Device and method for manually measuring normal thickness of large cavity deep radome

A measuring device and radome technology, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of manual adjustment and adjustment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

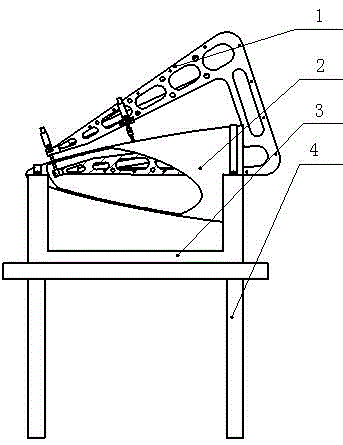

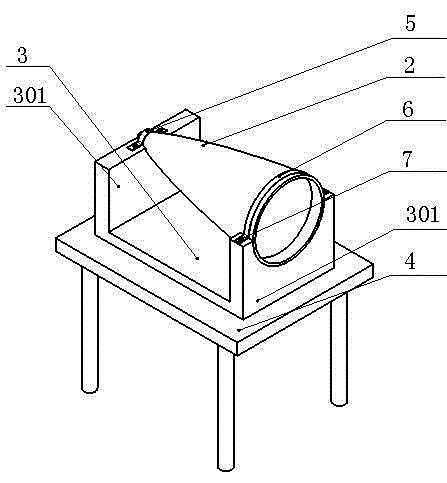

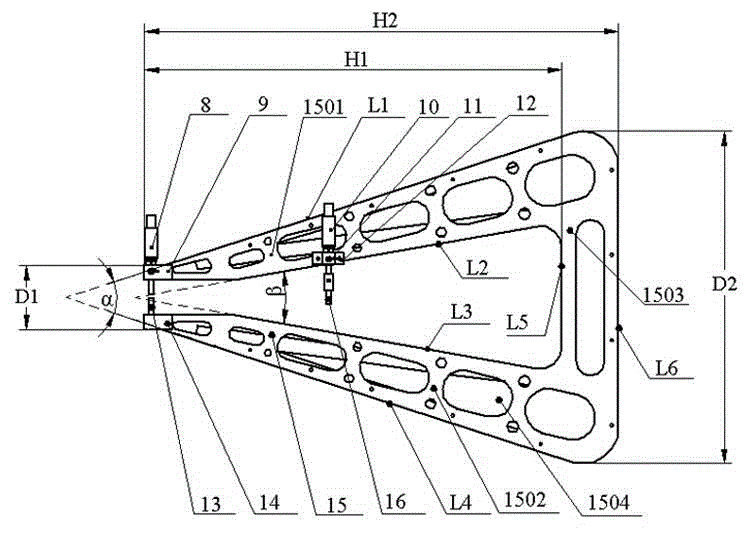

[0087] based on the following Figure 1 to Figure 6 , specifically describe the preferred embodiment of the present invention.

[0088] Such as figure 1 and figure 2 As shown, the present invention provides a manual measurement device for the normal thickness of a large-cavity deep radome, including a radome measurement fixture and a hand-held radome normal thickness caliper 1, and the radome measurement fixture is placed on the measuring platform 4, fix the radome 2 on the radome measurement fixture, and use the hand-held radome normal thickness caliper 1 to manually measure the normal thickness of the radome 2.

[0089] Such as figure 2 As shown, the described radome measurement fixture includes:

[0090] Measuring table 4, which is placed on the ground and welded by stainless steel, has a width of 600 mm in length, a length of 800 mm, and a height of 600 mm. The table top of measuring table 4 is horizontal;

[0091] Radome shelf 3, which is arranged on the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com