Workpiece laser measuring machine

A technology of laser measurement and measurement mechanism, applied in measurement devices, optical devices, instruments, etc., can solve the problems of easy fatigue, occupation of large workers, unreasonable design, etc., to ensure repeatability, continuity and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

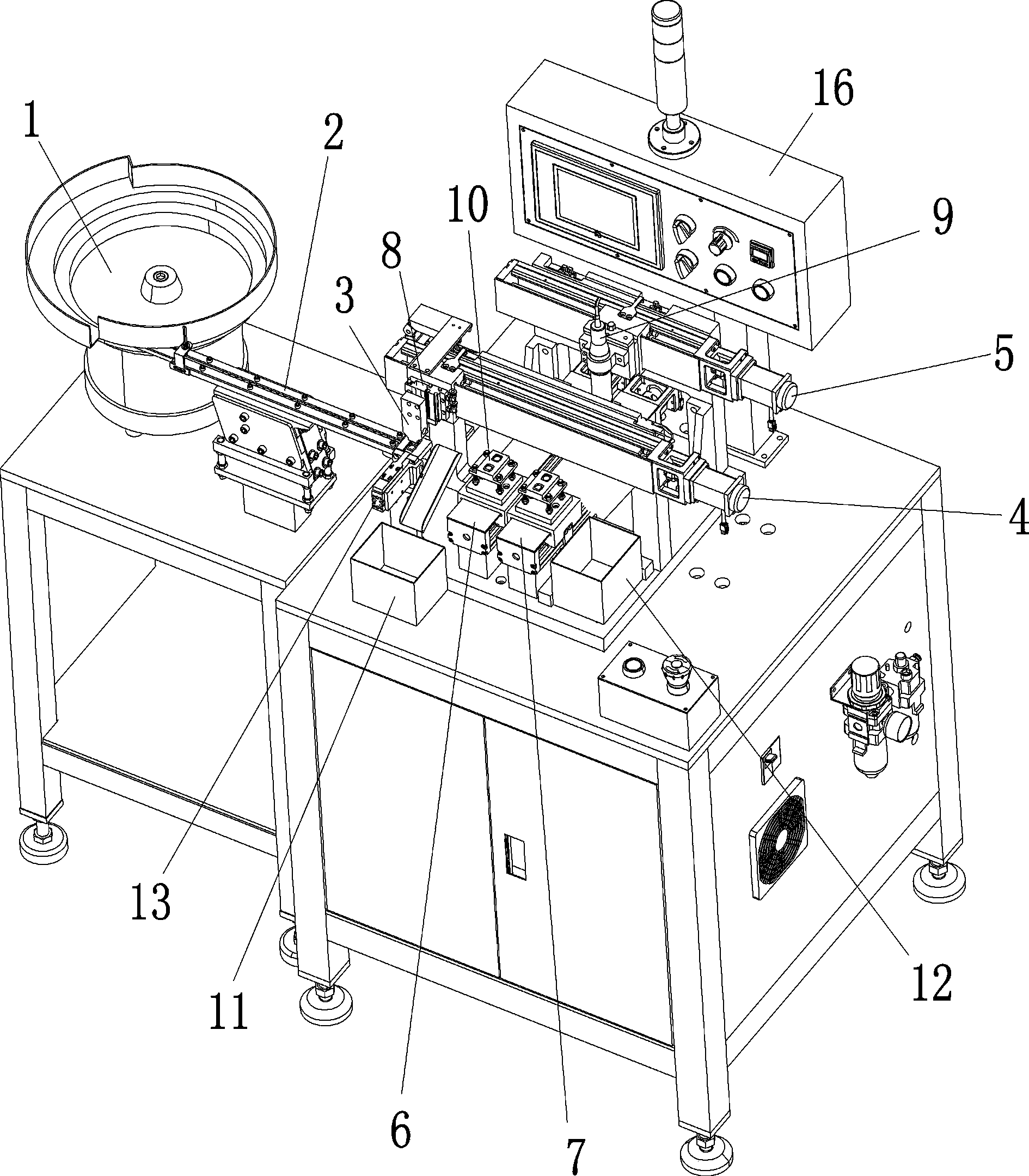

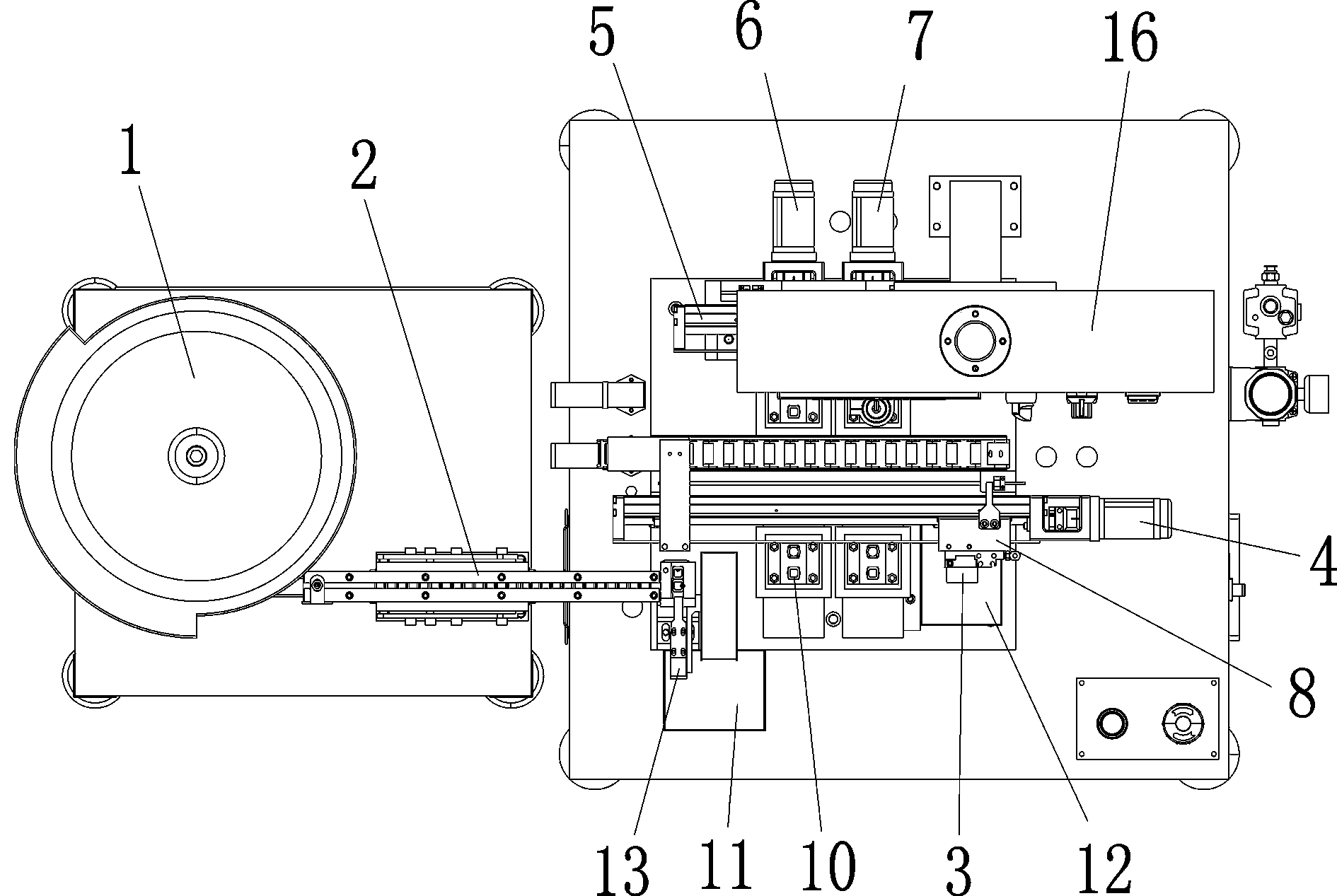

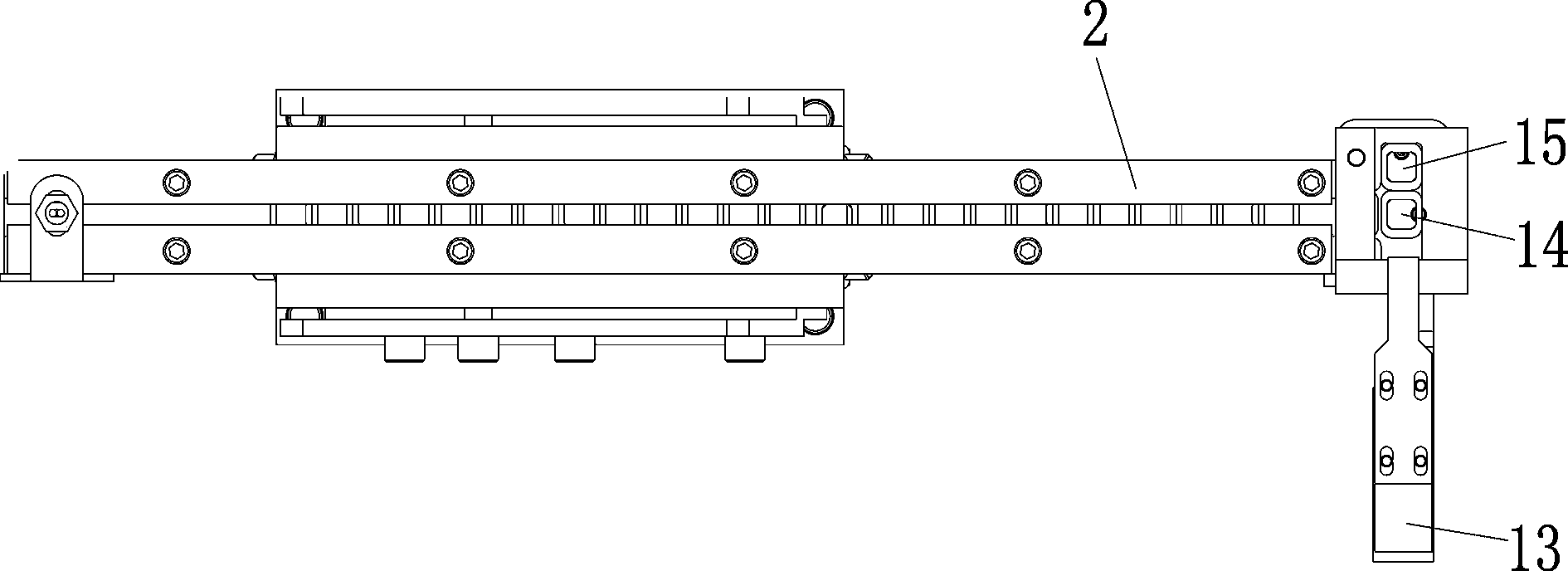

[0026] Such as figure 1 , 2 , Shown in 3, a kind of workpiece laser measuring machine comprises a feeding mechanism, a feeding mechanism and a measuring mechanism; the feeding mechanism is used for feeding, and includes a disc vibrating device 1 and a linear vibrating device 2, and the workpiece is obtained from the described The disc vibrating device 1 is arranged in the linear vibrating device 2; the transport mechanism is used for taking, loading and unloading, including a moving device and a manipulator 3; the measuring mechanism is used for data detection of workpieces , comprising a laser measuring head 9; the manipulator 3 and the laser measuring head 9 are installed in the moving device, and the moving device controls the simultaneous operation of the manipulator 3 and the laser measuring head 9; the manipulator 3 will The workpiece is transported t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com