Air cylinder control gear removal test device

A test device and gear removal technology, which is applied in the field of air cylinder control gear removal test device, can solve the problems of delay in construction period and large rework cost, and achieve the effects of accurately ensuring pressure, improving production efficiency, and controlling the quality of the air cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

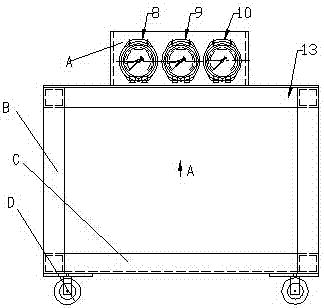

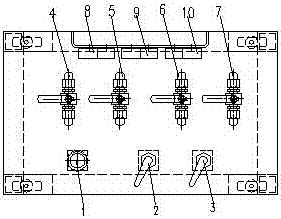

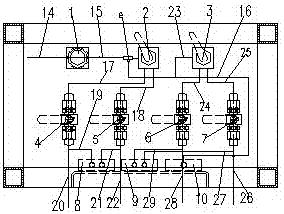

[0030] In the present invention figure 1 , figure 2 , image 3 And in the embodiment, use metal bar b and metal bar c to be welded rectangular test stand 13, the first and the second two support plates are respectively welded in the rectangular test stand 13, four square metal upright column bottoms of rectangular test stand 13 Universal wheel d is installed on the end. A metal plate a is installed on the upper surface of the rear side of the rectangular test stand 13 . Install and fix the first double-needle pressure gauge 8, the second double-needle pressure gauge 9 and the single-needle pressure gauge 10 on the top metal plate a in sequence with bolts respectively.

[0031] Connect the pressure reducing valve, the first manual valve, the second manual valve, the first cut-off plug door, the second cut-off plug door, the second The three cut-off plugs, the fourth cut-off plug, the first double-needle pressure gauge, the second double-needle pressure gauge, the single-ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com