Local positioning method of one-dimensional material

A positioning method and local technology, applied in the field of nanomaterials, can solve the problems of expensive equipment and complex optical signal process, and achieve the effect of reversible effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The "one-dimensional material" referred to in the present invention is a nano-scale one-dimensional material or a micron-scale one-dimensional material, wherein the nano-scale one-dimensional material includes nanowires, nanotubes, nanobelts, nanofibers or nanorods.

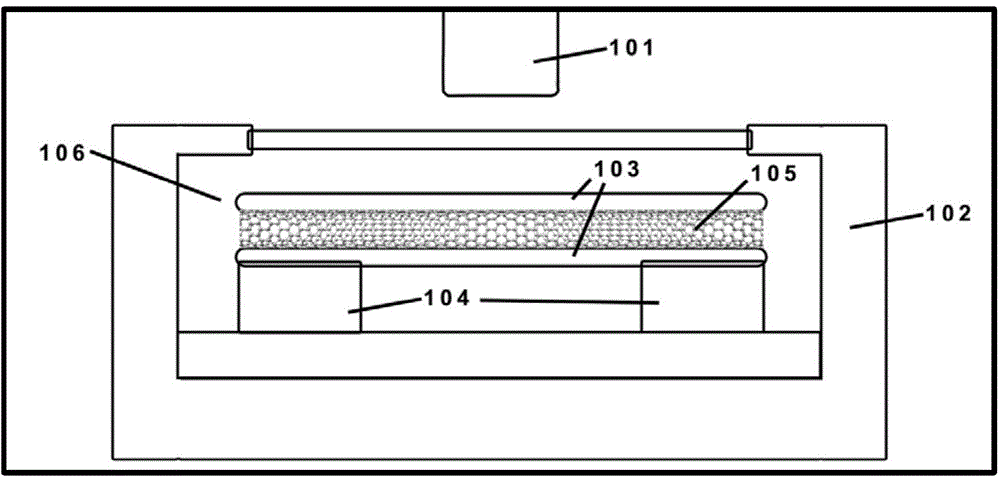

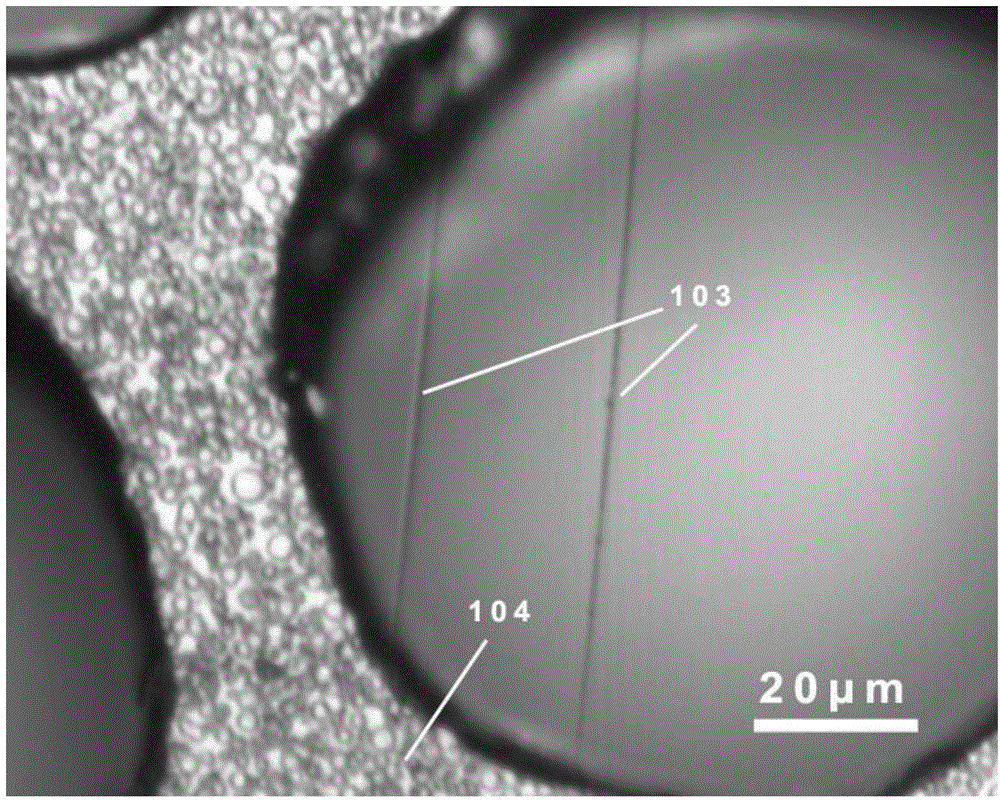

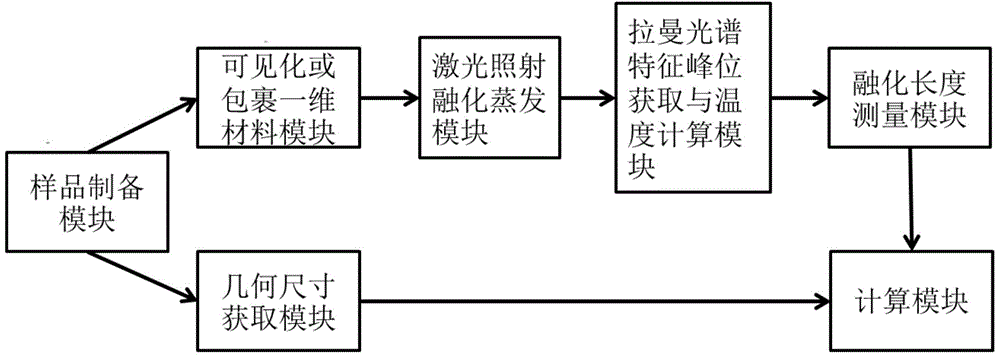

[0054] In order to solve the problems of extremely small one-dimensional materials, such as expensive equipment such as scanning electron microscope or even transmission electron microscope, complicated steps, high requirements on the production process and sample properties, etc., as well as the extremely small The one-dimensional material of the size cannot be positioned, so that subsequent operations cannot be performed. The present invention provides a local positioning method for one-dimensional materials, which is used for local positioning of one-dimensional materials under one observation condition, so as to The required subsequent manipulations are performed locally on the one-dimensional material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com