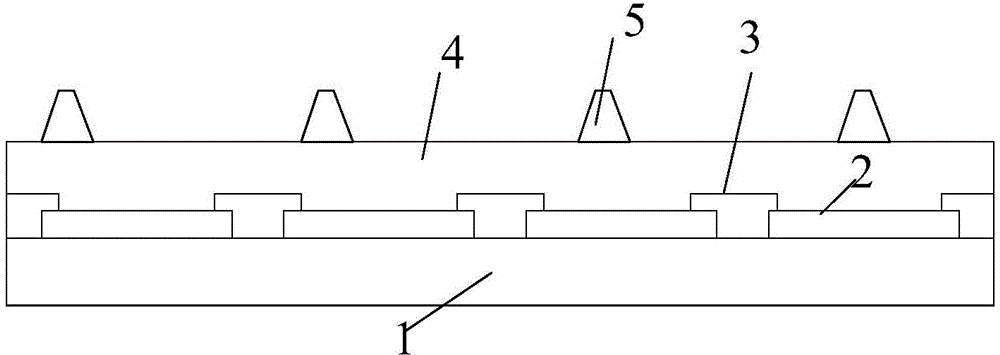

Array substrate and manufacturing method thereof and display device

A technology of an array substrate and a manufacturing method, applied in the field of display, can solve the problems of loss of transmittance of display panel, large step difference of color filter substrate, increase of backlight cost, etc., so as to shorten the production time, reduce the step difference, and reduce the number of patterning processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

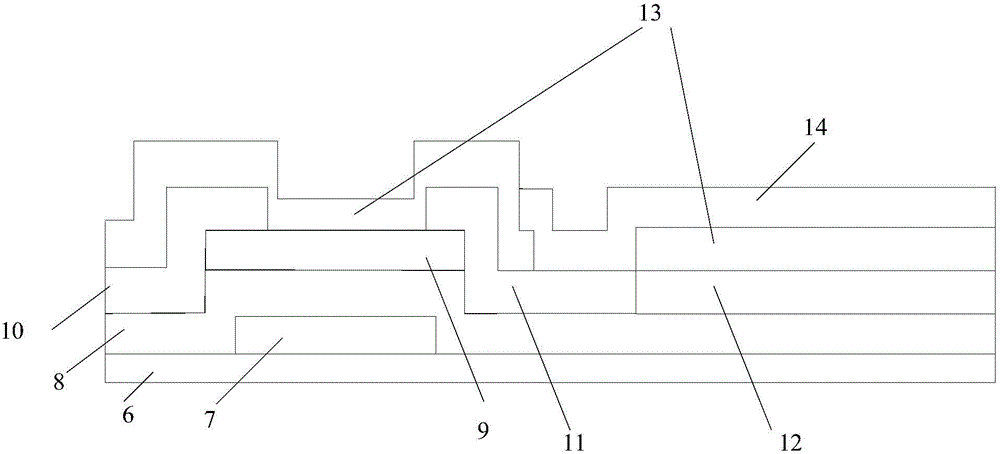

Embodiment 1

[0154] The array substrate in this embodiment is an array substrate in TN mode, and the method for manufacturing the array substrate in this embodiment specifically includes the following steps:

[0155] Step 1, providing a base substrate 6, forming patterns of gate electrodes 7 and gate lines on the base substrate 6;

[0156] Wherein, the base substrate 6 may be a glass substrate or a quartz substrate. Specifically, sputtering or thermal evaporation can be used to deposit a thickness of about The gate metal layer, the gate metal layer can be Cu, Al, Ag, Mo, Cr, Nd, Ni, Mn, Ti, Ta, W and other metals and alloys of these metals, the gate metal layer can be single-layer structure or multi-layer Structure, multi-layer structure such as Cu\Mo, Ti\Cu\Ti, Mo\Al\Mo, etc. A layer of photoresist is coated on the gate metal layer, and a mask is used to expose the photoresist, so that the photoresist forms a photoresist unreserved area and a photoresist reserved area, wherein the phot...

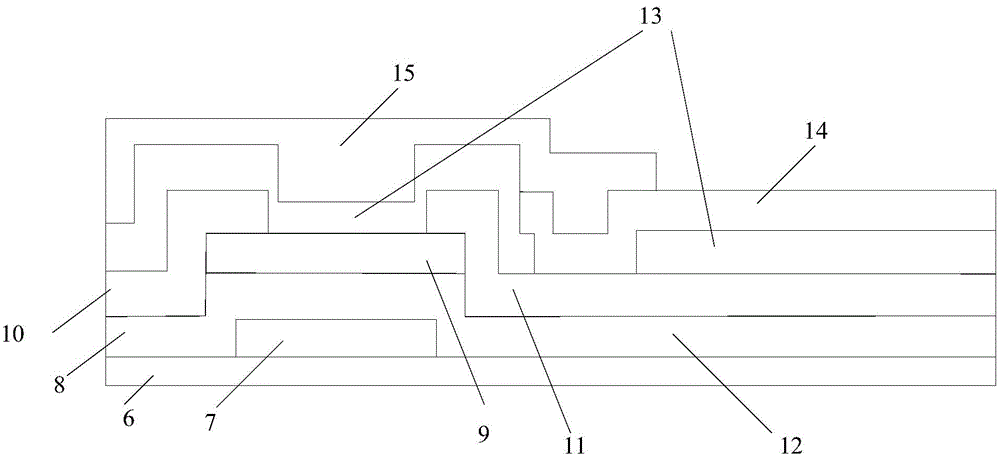

Embodiment 2

[0172] The array substrate in this embodiment is an array substrate in TN mode, and the method for manufacturing the array substrate in this embodiment specifically includes the following steps:

[0173] Step 1, providing a base substrate 6, forming patterns of gate electrodes 7 and gate lines on the base substrate 6;

[0174] Wherein, the base substrate 6 may be a glass substrate or a quartz substrate. Specifically, sputtering or thermal evaporation can be used to deposit a thickness of about The gate metal layer, the gate metal layer can be Cu, Al, Ag, Mo, Cr, Nd, Ni, Mn, Ti, Ta, W and other metals and alloys of these metals, the gate metal layer can be single-layer structure or multi-layer Structure, multi-layer structure such as Cu\Mo, Ti\Cu\Ti, Mo\Al\Mo, etc. A layer of photoresist is coated on the gate metal layer, and a mask is used to expose the photoresist, so that the photoresist forms a photoresist unreserved area and a photoresist reserved area, wherein the phot...

Embodiment 3

[0188] The array substrate in this embodiment is an array substrate in ADS (Advanced Super Dimension Switch) mode, and the manufacturing method of the array substrate in this embodiment specifically includes the following steps:

[0189] Step 1, providing a base substrate, forming patterns of gate electrodes and gate lines on the base substrate;

[0190] Wherein, the base substrate may be a glass substrate or a quartz substrate. Specifically, sputtering or thermal evaporation can be used to deposit a thickness of about The gate metal layer, the gate metal layer can be Cu, Al, Ag, Mo, Cr, Nd, Ni, Mn, Ti, Ta, W and other metals and alloys of these metals, the gate metal layer can be single-layer structure or multi-layer Structure, multi-layer structure such as Cu\Mo, Ti\Cu\Ti, Mo\Al\Mo, etc. A layer of photoresist is coated on the gate metal layer, and a mask is used to expose the photoresist, so that the photoresist forms a photoresist unreserved area and a photoresist reser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com