Anti-overheating electrical dynamic contact and structure thereof

A technology of moving contacts and contacts, which is applied in the direction of contact surface shape/structure, contact heating/cooling, etc. It can solve the problems of rapid recovery limitation of contacts, difficulty in quickly finding spares, and temperature rise at contact points, etc. , to achieve the effect of preventing contact heating, increasing the effective contact area, and enhancing the flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

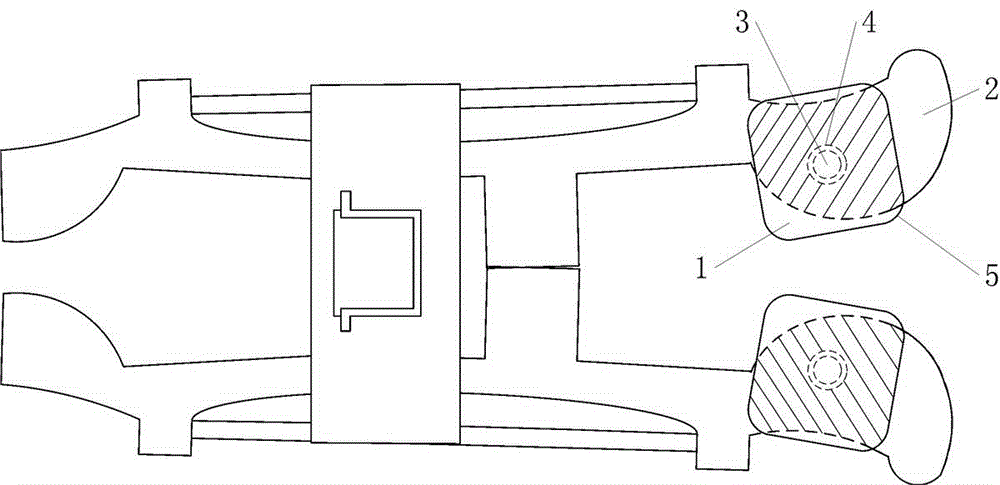

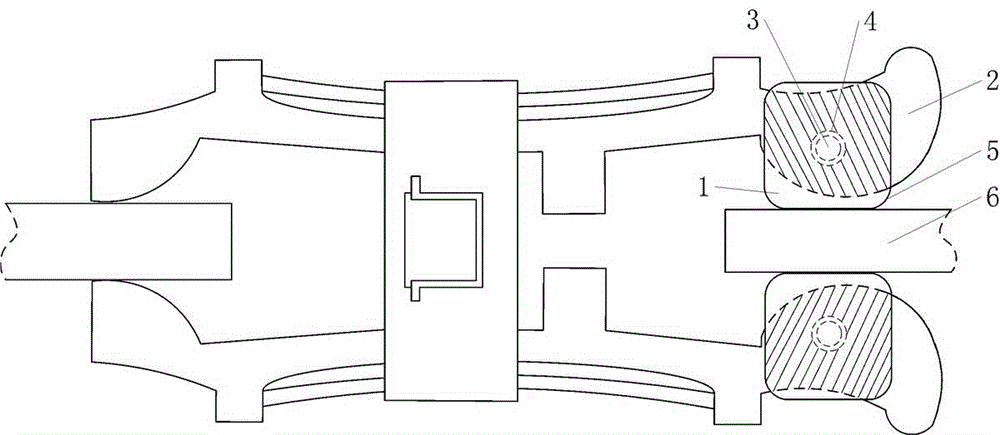

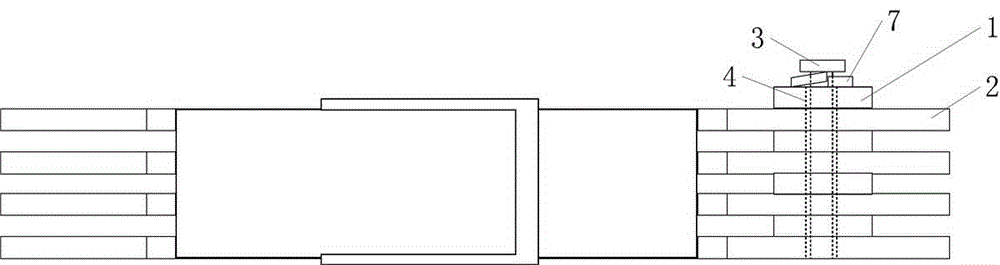

[0022] Such as figure 1 As shown, the moving contact structure of the present invention includes a movable part (1), a support part (2), and a fixed shaft (3). A shaft hole (4) is opened on the movable part (1) and the support part (2), and the fixed shaft (3) passes through the shaft hole (4), and the movable part (1) and the support part (2) are stacked and connected to the Together, make the two in close contact through the upper and lower sides. The electrical connection between the movable part (1) and the support part (2) is realized by close contact between the adjacent upper and lower surfaces, such as figure 1 The shaded part where the middle movable part (1) overlaps with the support part (2).

[0023] Such as figure 2 As shown, the movable part (1) of the present invention is a square, the four corners are arc-shaped chamfers (5), and the shaft hole (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com