Regeneration method of cation exchange resin for amino acid analysis

A technology of cation exchange and amino acid, which is applied in the direction of ion exchange regeneration, ion exchange, chemical instruments and methods, etc., can solve the problems of resin regeneration interference, high resin loss, poor operability, etc. Few, highly operable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

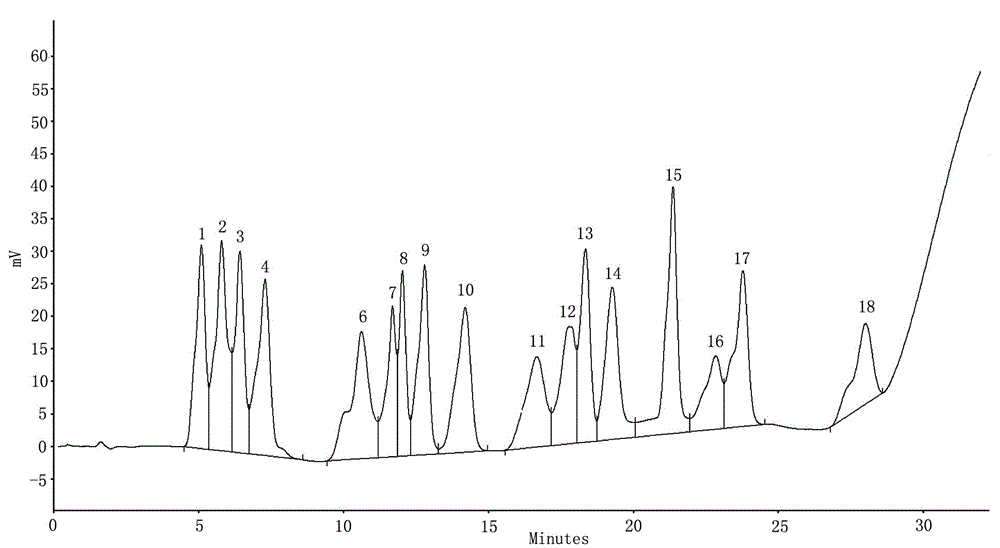

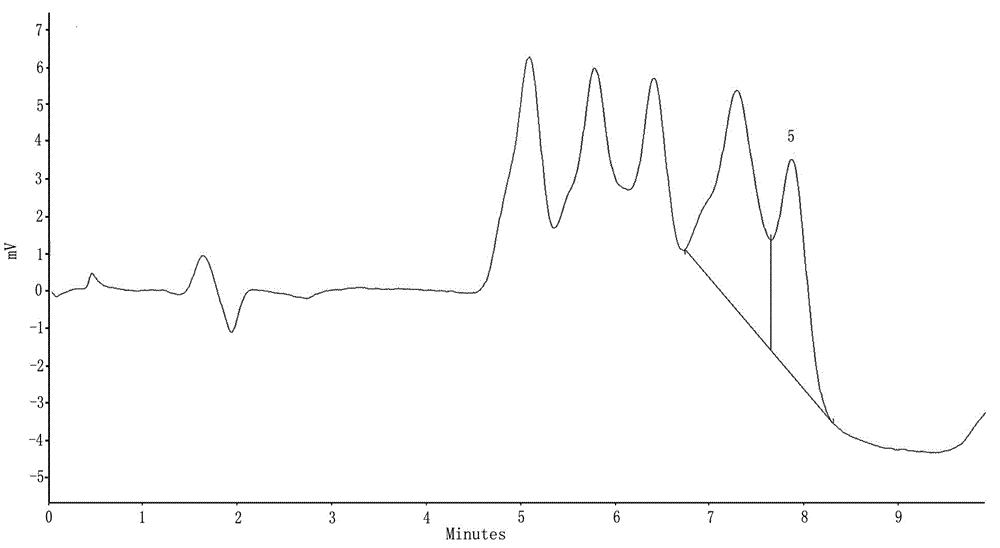

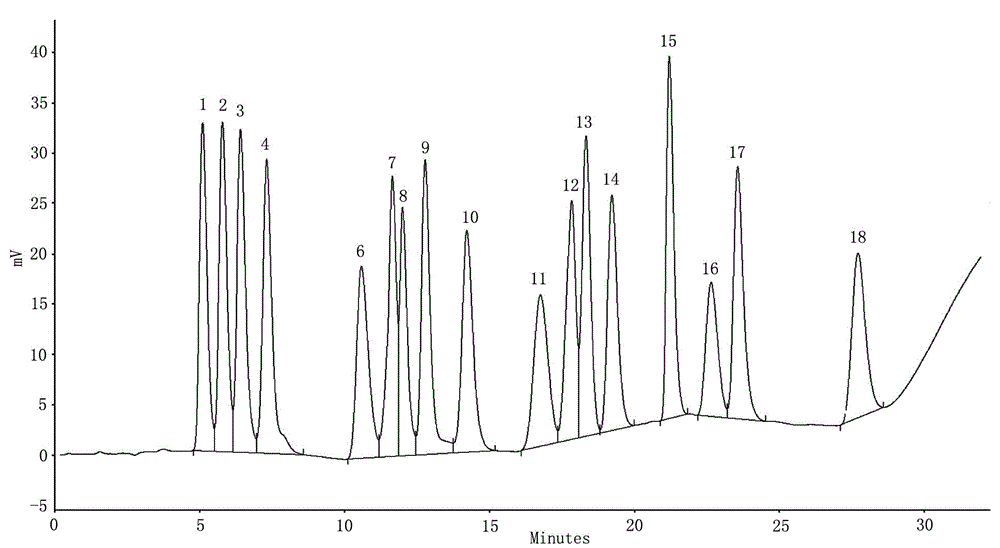

Image

Examples

no. 1 example

[0033] Cation exchange resin to be regenerated: The amino acid analysis column of L-8900 Hitachi Amino Acid Automatic Analyzer decreases after being used for a period of time, and the cation exchange resin in the separation column is taken out as the cation exchange resin to be regenerated.

[0034] Ultrasonic instrument: ultrasonic cleaning machine (D-78224 Singen / Htw); ultrasonic cleaning parameters: frequency 26 KHz, power 60W, temperature 22°C, duration 5 minutes, medium is water, water level is higher than the lowest in the ultrasonic container water line.

[0035] Centrifugation conditions: the rotation speed is 4000 rpm, and the duration is 5 minutes.

[0036] The amount of reagent used for each ultrasonic cleaning: 15 mL / g resin.

[0037] Regeneration steps: put 15 grams of the cation exchange resin to be regenerated into a centrifuge tube (the material of the centrifuge tube is polypropylene), and then use ultrapure water to ultrasonically clean once, acetone ultraso...

no. 2 example

[0049] Cation exchange resin to be regenerated: The amino acid analysis column of L-8900 Hitachi Amino Acid Automatic Analyzer is used for a period of time, and the column efficiency decreases. The cation exchange resin in the separation column is taken out as the cation exchange resin to be regenerated.

[0050] Ultrasonic instrument: ultrasonic cleaning machine (D-78224 Singen / Htw); ultrasonic cleaning parameters: frequency 28KHz, power 60W, temperature 0°C, duration 3 minutes, medium is water, water level is higher than the lowest water level in the ultrasonic container line.

[0051] Centrifugation conditions: the rotation speed is 3000 rpm, and the duration is 3 minutes.

[0052] The amount of reagent used for each ultrasonic cleaning: 18 mL / gram of resin.

[0053] Regeneration steps: put 18 grams of the cation exchange resin to be regenerated into a centrifuge tube (the material of the centrifuge tube is polypropylene), and then use ultrapure water to ultrasonically clean...

no. 3 example

[0065] Cation exchange resin to be regenerated: The amino acid analysis column of L-8900 Hitachi Amino Acid Automatic Analyzer decreases after being used for a period of time, and the cation exchange resin in the separation column is taken out as the cation exchange resin to be regenerated.

[0066] Ultrasonic instrument: ultrasonic cleaning machine (D-78224 Singen / Htw); ultrasonic cleaning parameters: frequency 30KHz, power 60W, temperature 30°C, duration 4 minutes, medium is water, water level is higher than the lowest water level in the ultrasonic container line.

[0067] Centrifugation conditions: the rotating speed is 5000 rpm, and the duration is 4 minutes.

[0068] The amount of reagent used for each ultrasonic cleaning: 20 mL / gram of resin.

[0069] Regeneration steps: put 20 grams of the cation exchange resin to be regenerated into a centrifuge tube (the material of the centrifuge tube is polypropylene), and then ultrasonically clean it once with ultrapure water, onc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com