Target material sand blasting clamp and target material sand blasting method

A target material and sandblasting technology, which is applied in the direction of manufacturing tools, abrasive jetting machine tools, metal material coating technology, etc., can solve the problems of scratches on the sputtering surface, uneven force, complex shape, etc., to ensure that the sandblasting quality, improve blasting efficiency, and save the cost of tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background section, the accuracy of blasting the sandblasting area in the target material through tape protection is poor, and the size of the sandblasting area is difficult to ensure, which affects the formation position of the reverse sputtering film. Moreover, when removing the tape beyond the sputtering area by blade cutting technology, it is easy to leave scratches on the sputtering surface, which affects the adhesion of the anti-sputtering film.

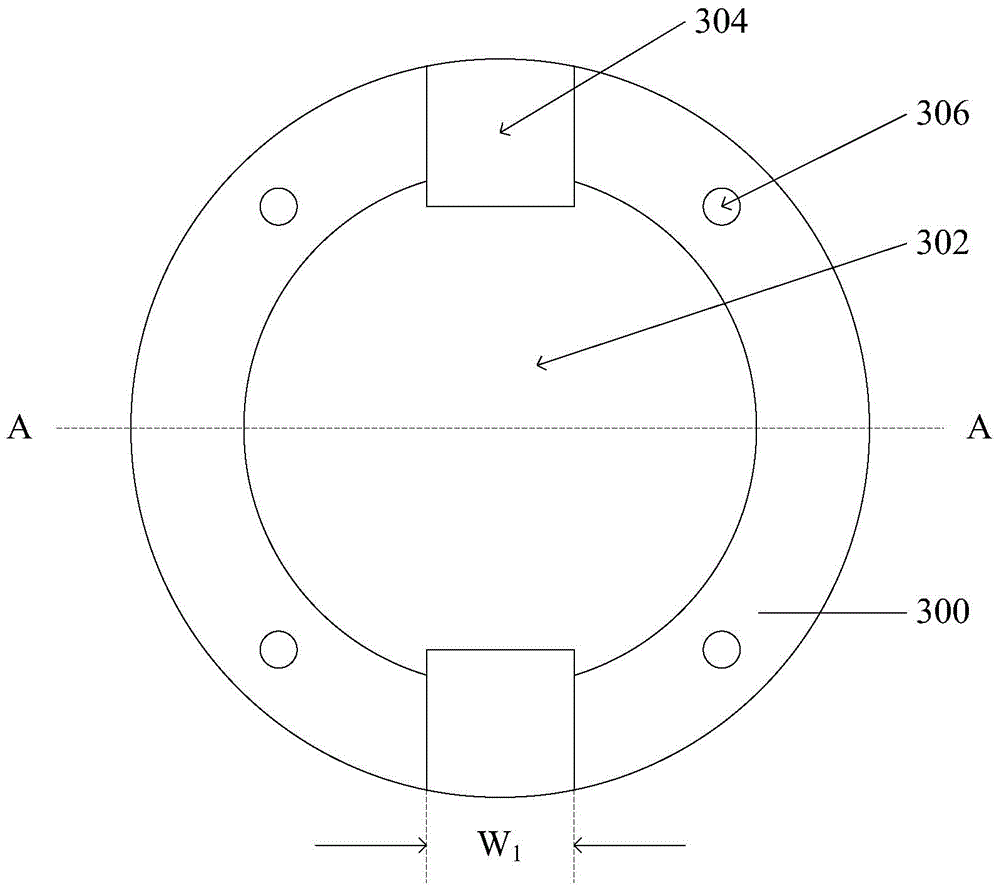

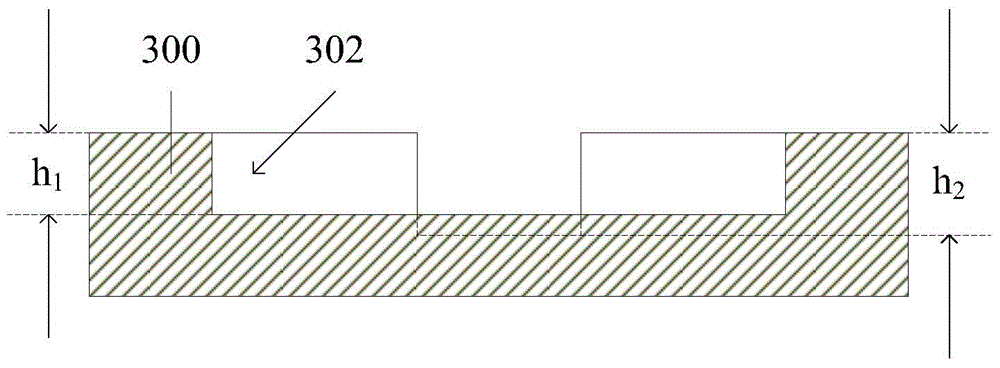

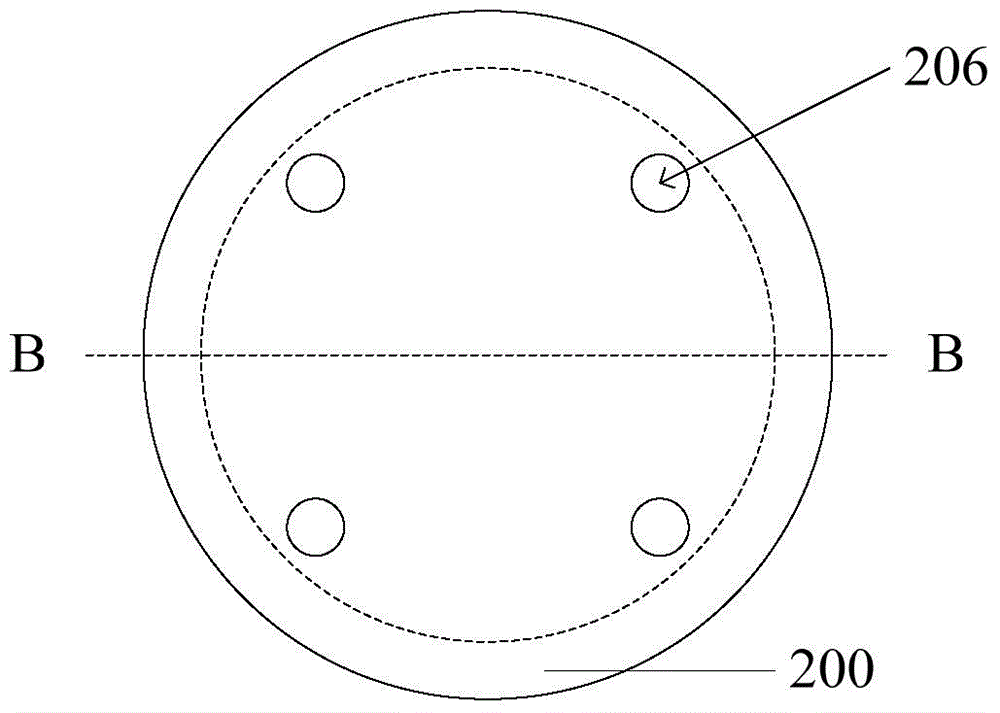

[0035] The invention provides a target sandblasting fixture comprising a target chuck, a cover plate and more than two connectors. Before sandblasting, the target is placed in the first groove of the target chuck, and The sputtering area of the target is opposite to the bottom surface of the first groove, and the cover plate is placed on the sputtering area of the target, and the first end of the connector is fixed on the target chuck outside the first groove , fix the second end of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com