Method for spraying marks on surface of high-temperature object

A high-temperature object and marking technology, which is applied in the field of spraying marking on the surface of high-temperature objects and the surface marking of high-temperature products, can solve problems such as burrs and missing spray points, limited characters or patterns, and difficulty in compatibility, etc., to achieve equipment structure and Simple system structure, improved reliability and maintainability, and reduced procurement and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

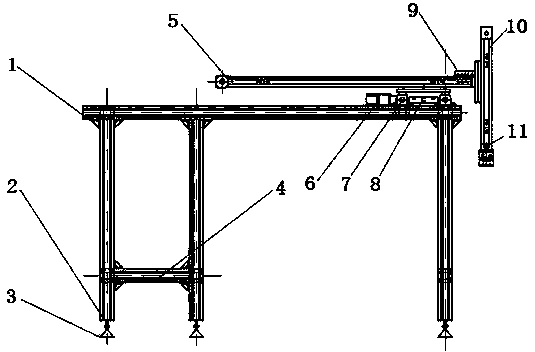

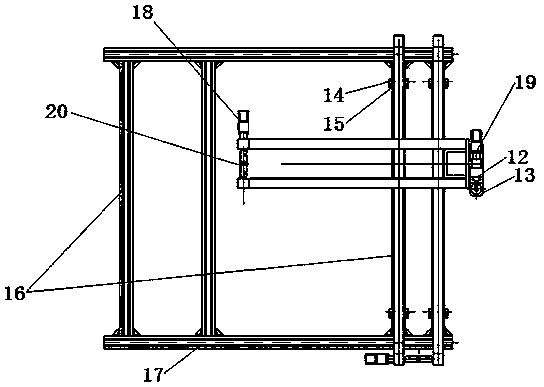

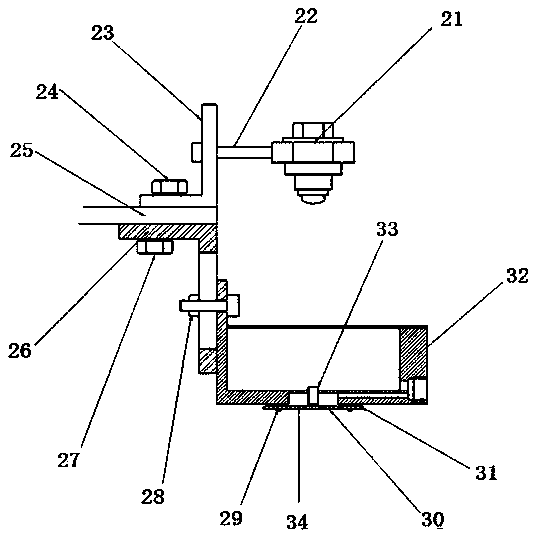

[0045]The drawings of the present invention are as follows: 1-reinforced corner piece; 2-column; 3-supporting foot; 4-connecting column 1; 5-Y axis linear module; 6-X axis servo motor; 7-X axis line Module; 8-X-axis synchronization rod; 9-valve box; 10-Z-axis linear module; 11-nozzle connector; 12-nozzle seat; 13-beam device; 14-installation base plate; 15-fixed block ;16-working beam; 17-beam; 18-Y-axis servo motor; 19-Z-axis servo motor; 20-Y-axis synchronization rod; 21-paint nozzle; 22 nozzle fixing screw; Screw; 25-fixed bottom plate; 26-adjusting plate; 27-fixing screw; 28-fixing bolt, nut; 29-screw; 30-hole plate; 31-sealing gasket; 32-beam plate; -Negative pressure hole; 35-computer; 36-servo control card; 37-terminal board; 38-servo controller; 39-AC servo motor; 40-manual ball valve; 41-air filter; 42-pressure regulating valve; 43 -atomizing gas solenoid valve; 44-cleaning water valve; 45-paint valve; 46-cleaning water valve control solenoid valve; 47-paint valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com