Oil-water separation device

An oil-water separation device, oil-water separation technology, applied in the direction of grease/oily substance/floating matter removal device, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of solid residues that are difficult to remove, oil, water , impurity sludge is difficult to separate and other problems, to achieve the effect of improving efficiency, avoiding clogging and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

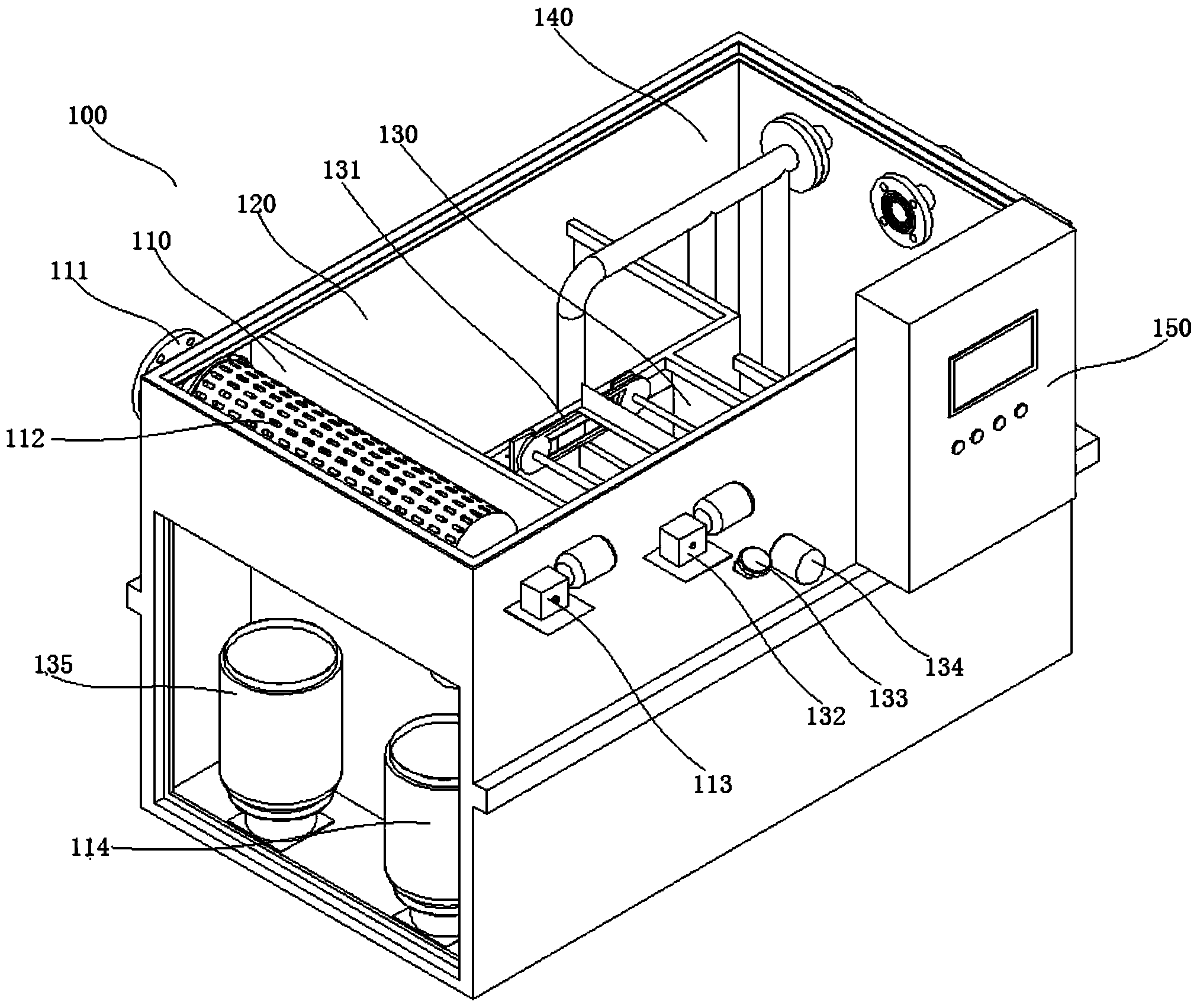

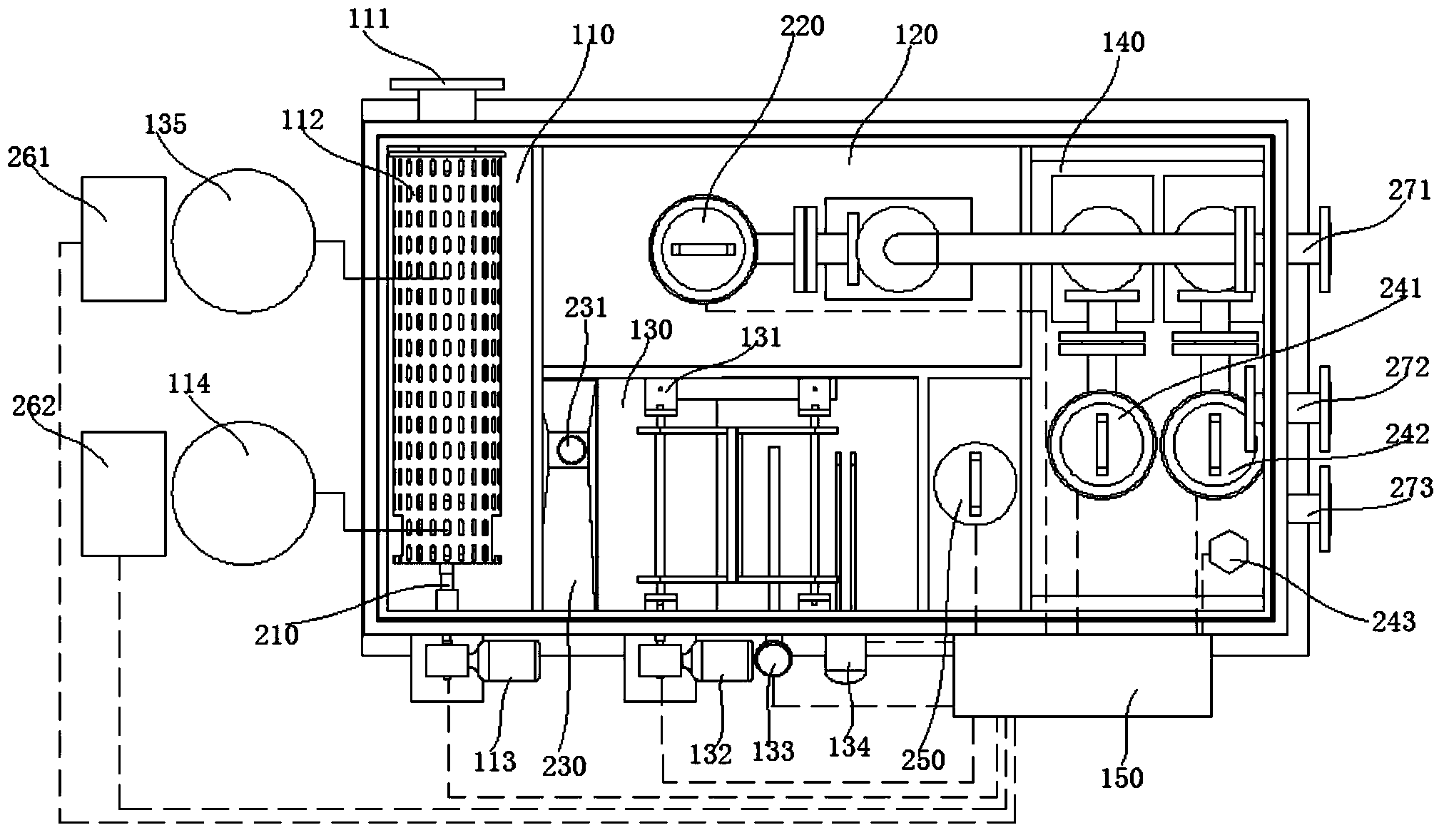

[0036] Such as figure 1 , figure 2 As shown, the oil-water separation device in this embodiment includes a device body 100. The device body 100 is provided with a water inlet 111 and a water outlet 271; the device body 100 is also provided with a slag removal chamber 110, a sedimentation chamber 120, and oil and water. Separating cavity 130 and water storage cavity 140;

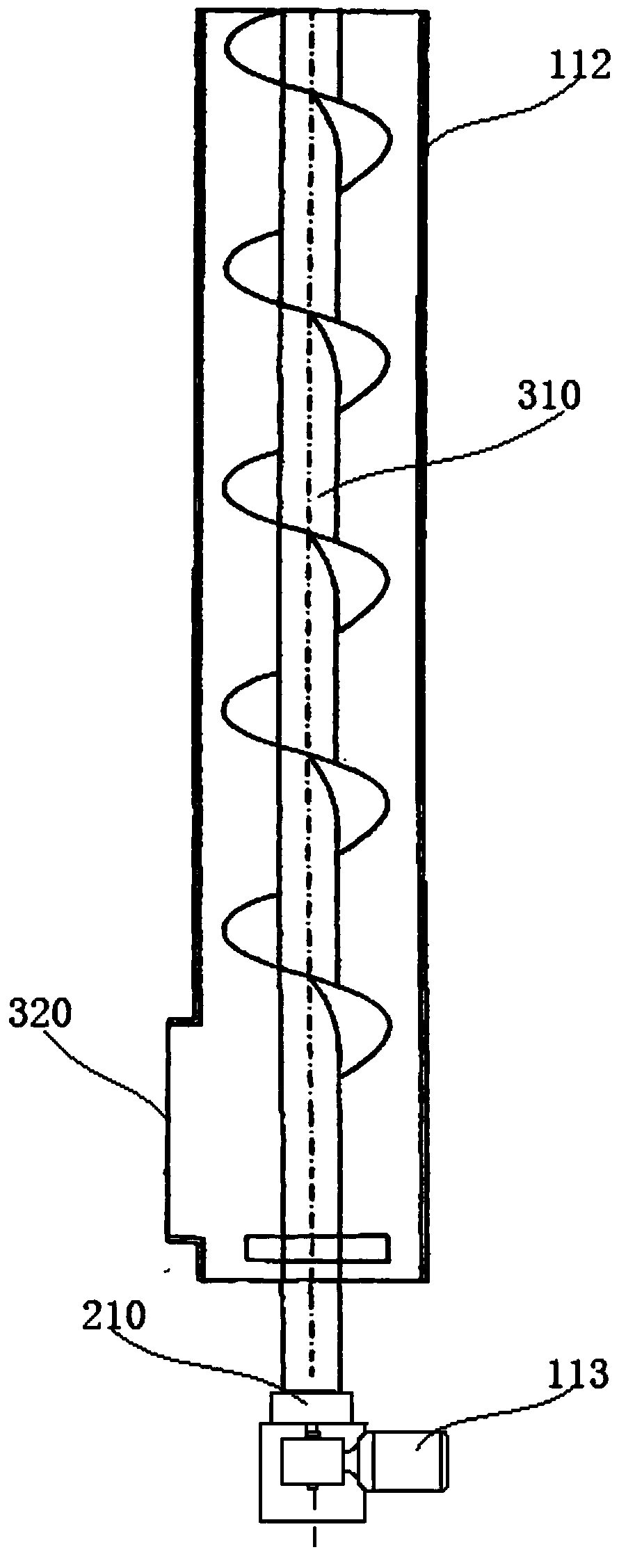

[0037] The deslagging chamber 110 is provided with a deslagging drum 112. The water inlet 111 communicates with the interior of the deslagging drum 112. The side wall of the deslagging drum 112 is structured in a grid shape; the sewage flows into the deslagging drum 112 from the water inlet 111 and flows from the deslagging drum 112. The side wall of the cylinder 112 flows out, and flows into the precipitation chamber 120 after the solid residue is removed, and flows into the oil-water separation chamber 130 after precipitation and removal of small particles in the precipitation chamber 120;

[0038] A submersibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com