Experimental method and experimental system of gas sealing performance of underground packer

A technology of sealing performance and gas sealing, applied in earthwork drilling, wellbore/well components, measurement, etc., to achieve the effects of improving safety, reducing operating costs, and extending maintenance periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

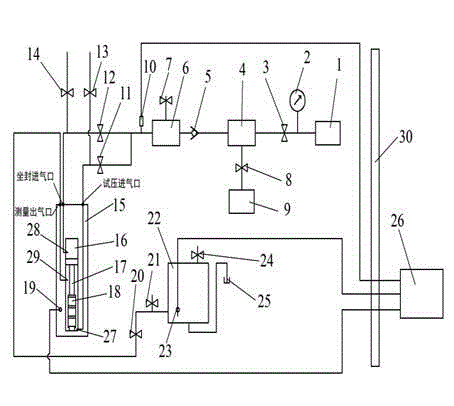

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail: see figure 1 , an experimental method for the gas sealing performance of a downhole packer is to install the simulated packer for the experiment in the high pressure cylinder 16, place the high pressure cylinder 16 in the constant temperature box 15, and pass the high pressure cylinder 16 and the constant temperature box 15 through the pressure test pipeline , the setting pipeline and the gas leakage collection pipeline are connected to the sealing performance experiment system to verify the sealing performance of the experimental simulated packer in the high pressure cylinder 16 . The experimental medium used in the sealing performance experiment system is CO 2 or N 2 . The simulated packer used in the experiment is provided with a setting piston 17 and a sealing member 18, both of which are installed on the center pipe to seal the annular space between the center pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com