Acid liquid safety transfer device and acid liquid transfer method

A technology for transferring device and acid solution, applied in liquid distribution, conveying or transferring device, device for controlling liquid flow, distribution device, etc., can solve problems such as operator injury and environmental pollution, and prevent acid solution from leaking and flowing out. Smooth and stable, no contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

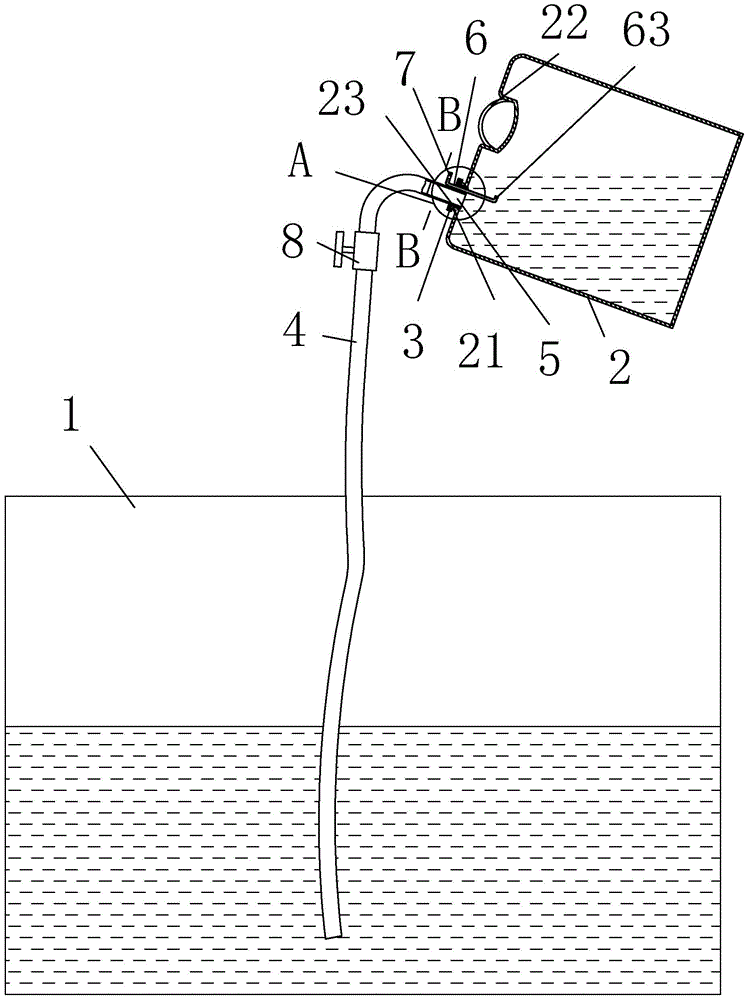

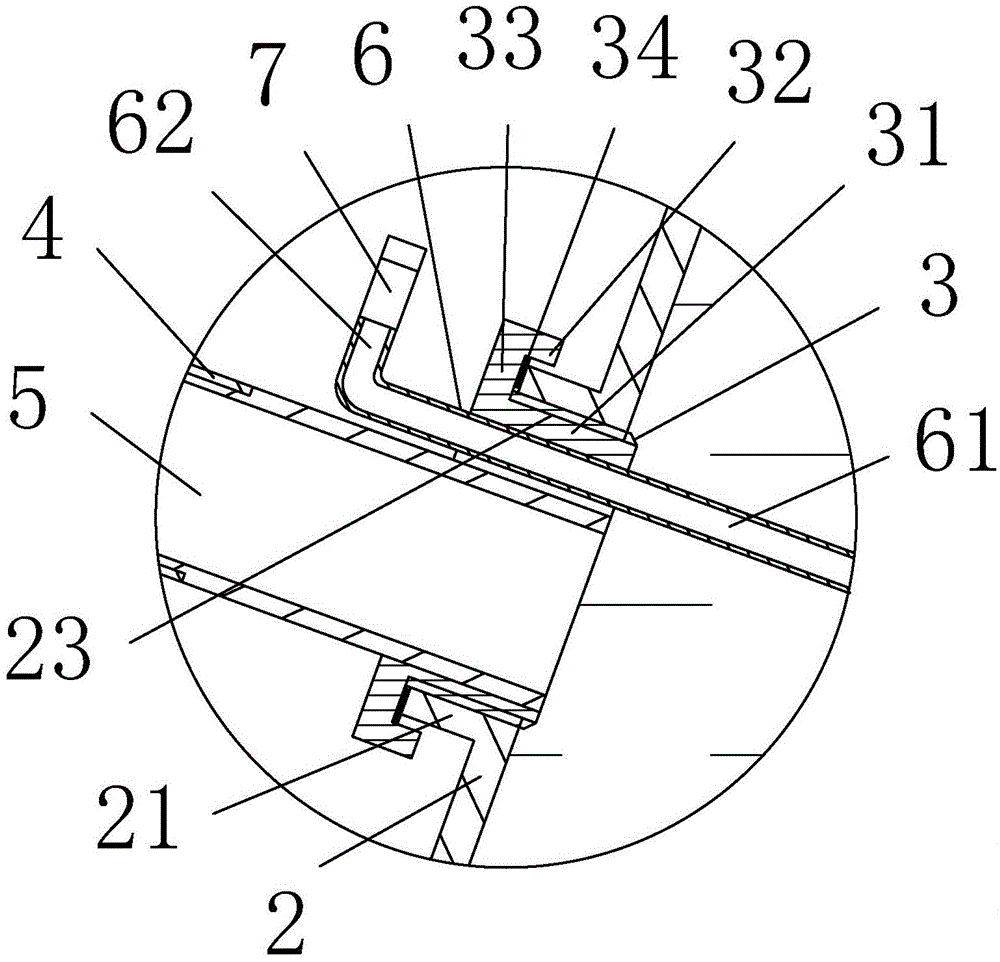

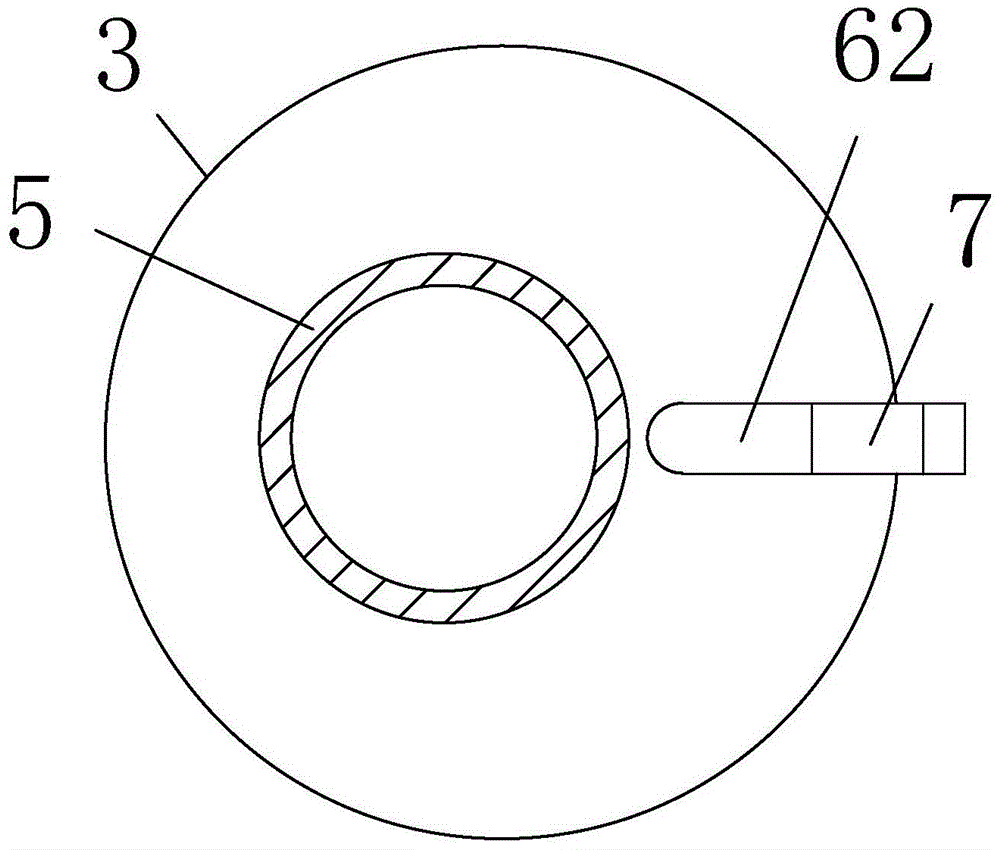

[0018] as attached figure 1 , attached figure 2 , attached image 3 Shown: an acid liquid safety transfer device, including a tank reactor 1 and an acid liquid bucket 2 with a round bump 21 and a handle 22 on the top; Threaded through hole 23; the acid liquid safety transfer device also includes a connecting cover 3, a connecting pipe 4, an acid liquid outlet pipe 5 and an air intake pipe 6 threaded in the connecting cover 3, which are threadedly connected with the internally threaded through hole 23 ; One end of the connecting pipe 4 is connected to one end of the acid outlet pipe 5; the other end of the connecting pipe 4 is a free end.

[0019] The connecting cover 3 includes a main body 31 threadedly connected with the internally threaded through hole 23, a protective ring 32 sleeved on the outside of the side wall of the round bump 21, and a connecting ring 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com