Prefabricated member for tertiary air hose elbow

A technology for pipe elbows and prefabricated parts, which is applied in the field of prefabricated parts for tertiary air pipe elbows, which can solve the problems of heavy maintenance workload, high maintenance cost, and short service life of prefabricated parts, so as to reduce the working intensity and prolong the service life , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

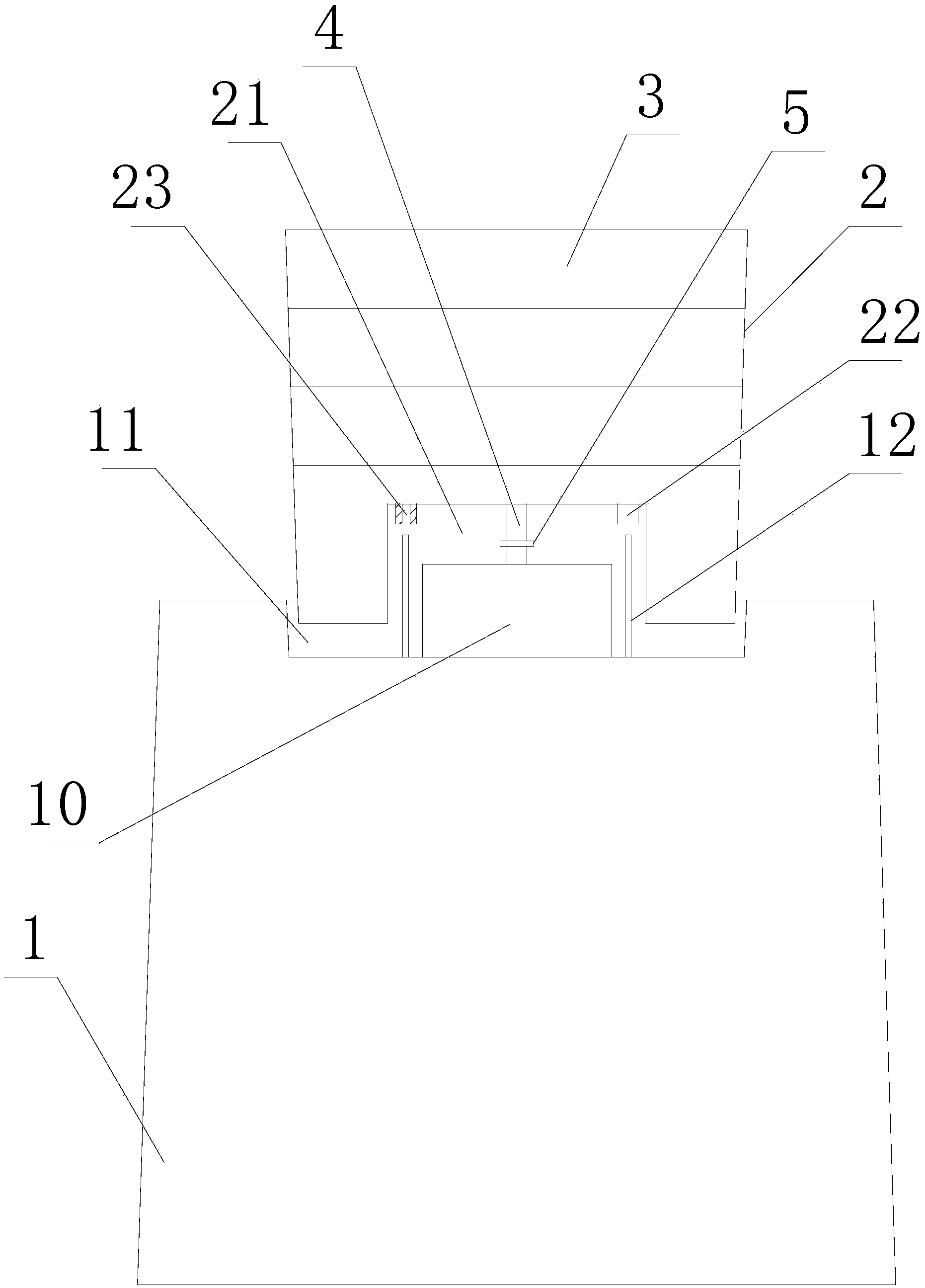

[0014] Such as figure 1 As shown, a prefabricated part for a tertiary air duct elbow, including a prefabricated brick body 1, the prefabricated brick body 1 is a pyramidal structure, and the top of the prefabricated brick body 1 is provided with a connecting boss 10, and the connecting boss A bump 2 is fixedly connected in the table 10, and the bottom end of the bump 2 is provided with a groove 21 matched with the connecting boss 10, and the bottom end of the bump 2 is provided with at least one for the bump 2 The screw rod 4 installed in the groove 21, the two ends of the screw rod 4 are respectively built in the groove 21 and the bump 2, and the top of the prefabricated brick body 1 is provided with a positioning groove 11 matching with the bump 2 , the connecting boss 10 is built in the positioning groove 11, and each outer wall of the protrusion 2 is provided with several guide vanes 3, the cross section of the guide vanes 3 is rectangular and the guide vanes 3 It is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com