Packaging structure for thermistor temperature coefficient calibration

A thermistor and temperature coefficient technology, applied in thermometers, thermometer testing/calibration, measuring devices, etc., can solve problems such as unsatisfactory, calibration failure, medium pollution, etc., and achieve the effect of convenient operation, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

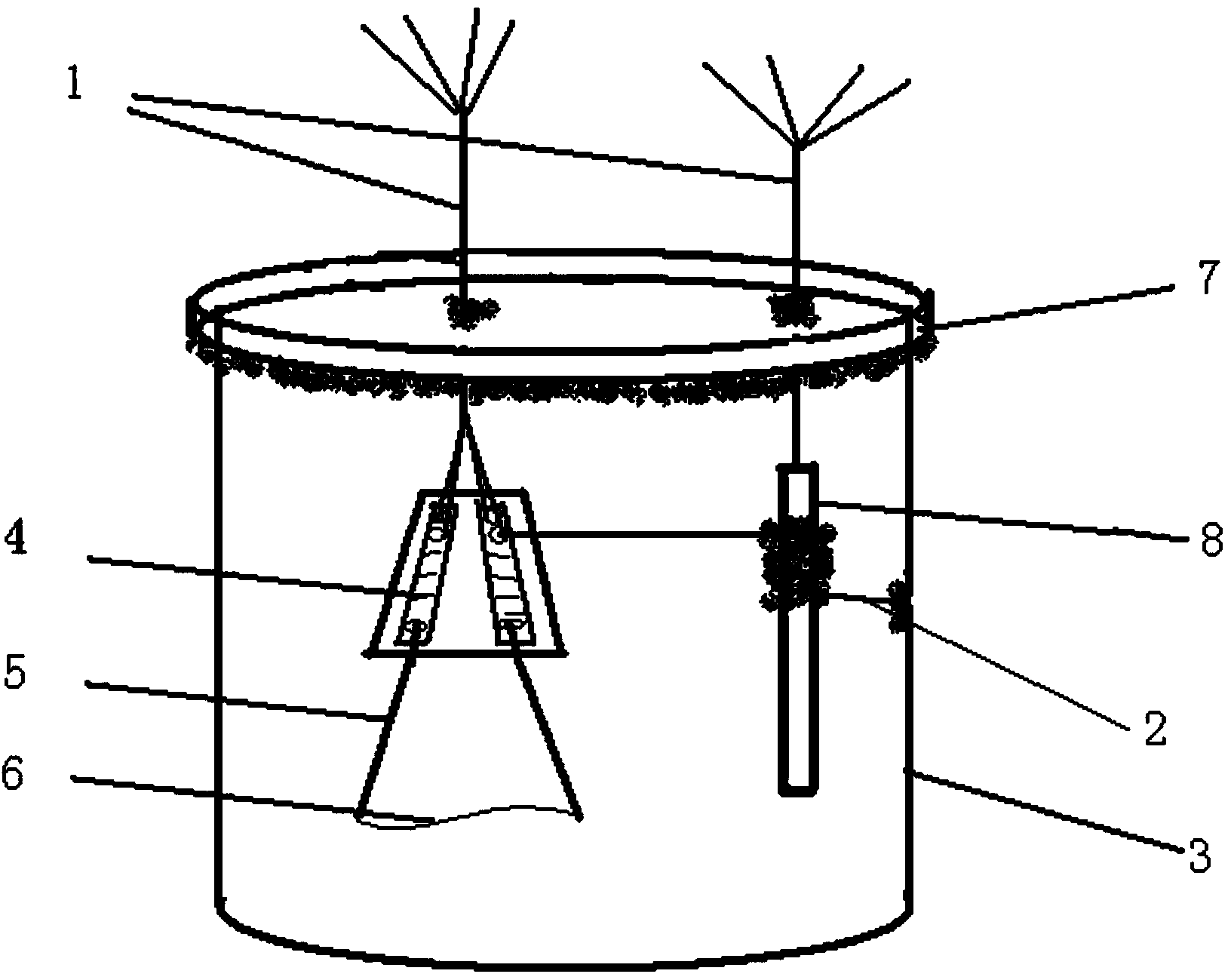

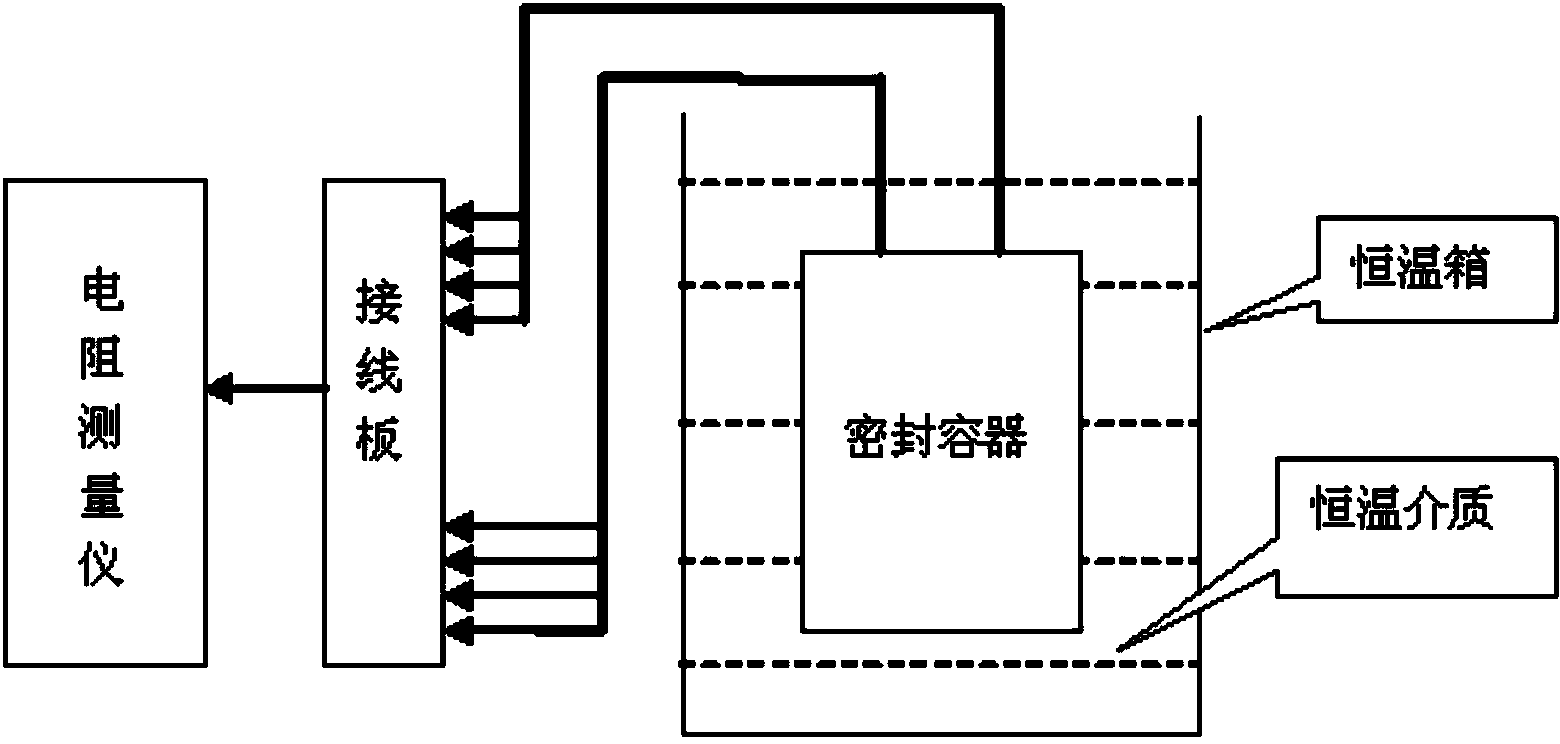

Image

Examples

Embodiment 1

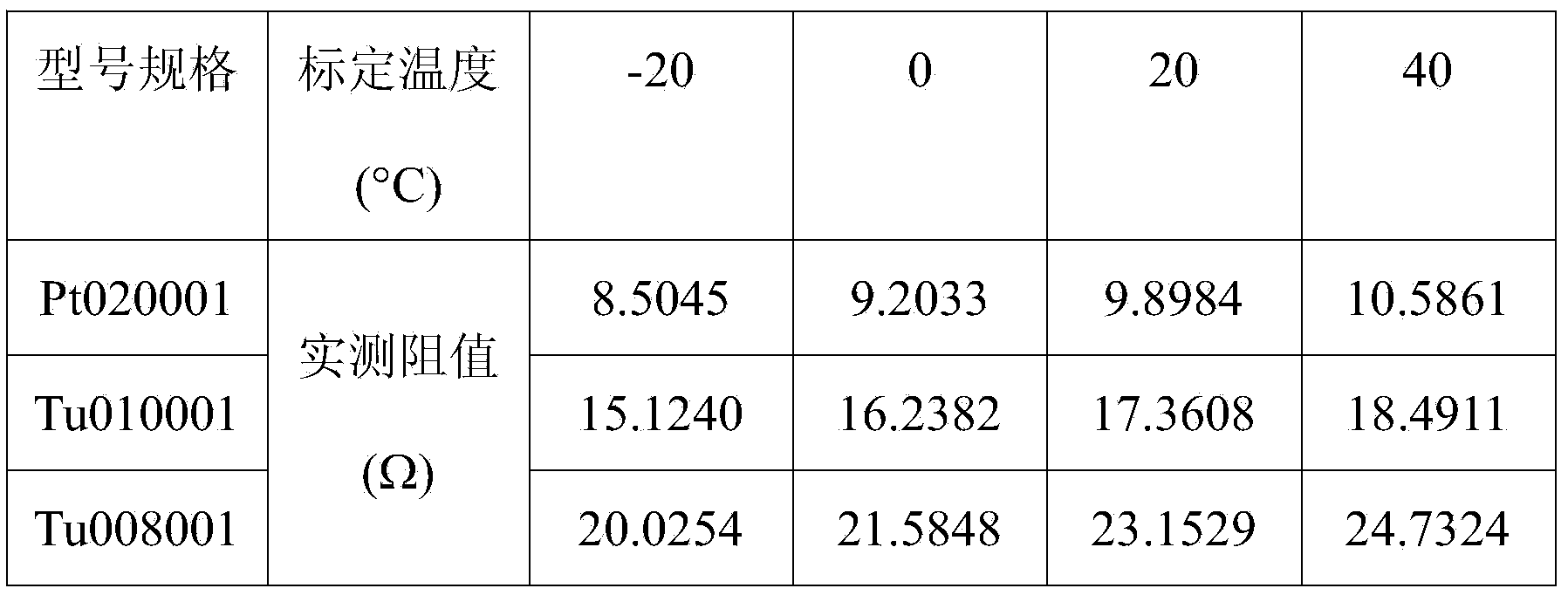

[0031] The three temperature sensors to be calibrated at the four temperature points of -20℃, 0℃, +20℃ and +40℃ were calibrated in real time. The results are as follows:

[0032] Verification Regulation: JJG229-2010 Verification Regulation of Industrial Platinum and Copper Thermal Resistance

[0033] Equipment: Super resistance thermometer 5~400Q, uncertainty U=5*10 -6 Q, k=2,

[0034] Standard platinum resistance thermometer -189.344~419.527℃

[0035] Platinum wire: Pt020001 (20μm diameter)

[0036] Tungsten wire: Tu010001 (10μm diameter)

[0037] Tungsten wire: Tu008001 (8μm diameter)

[0038] Table 1 shows the resistance values of three thermistors to be calibrated at different temperatures. Then, the temperature coefficients of the three thermistors to be calibrated are obtained by linear fitting, as shown in Table 2:

[0039] Table 1

[0040]

[0041] Table 2

[0042] Model specification

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com