Irregular shale sample and preparation method thereof as well as ultrasonic testing device

A technology of rules and samples, which is applied in the preparation of test samples and the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of high cost and difficulty, and difficulty in obtaining regular samples, and achieve fast rock testing and convenient acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

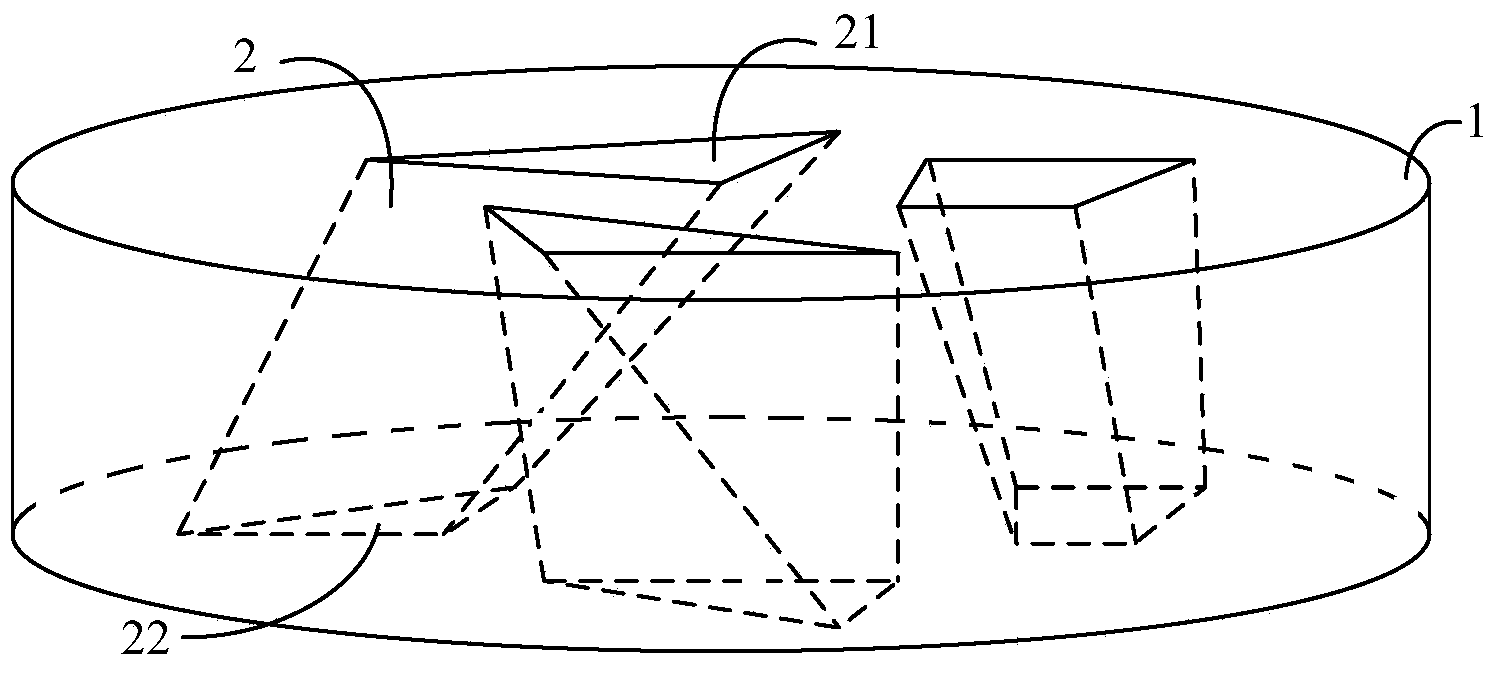

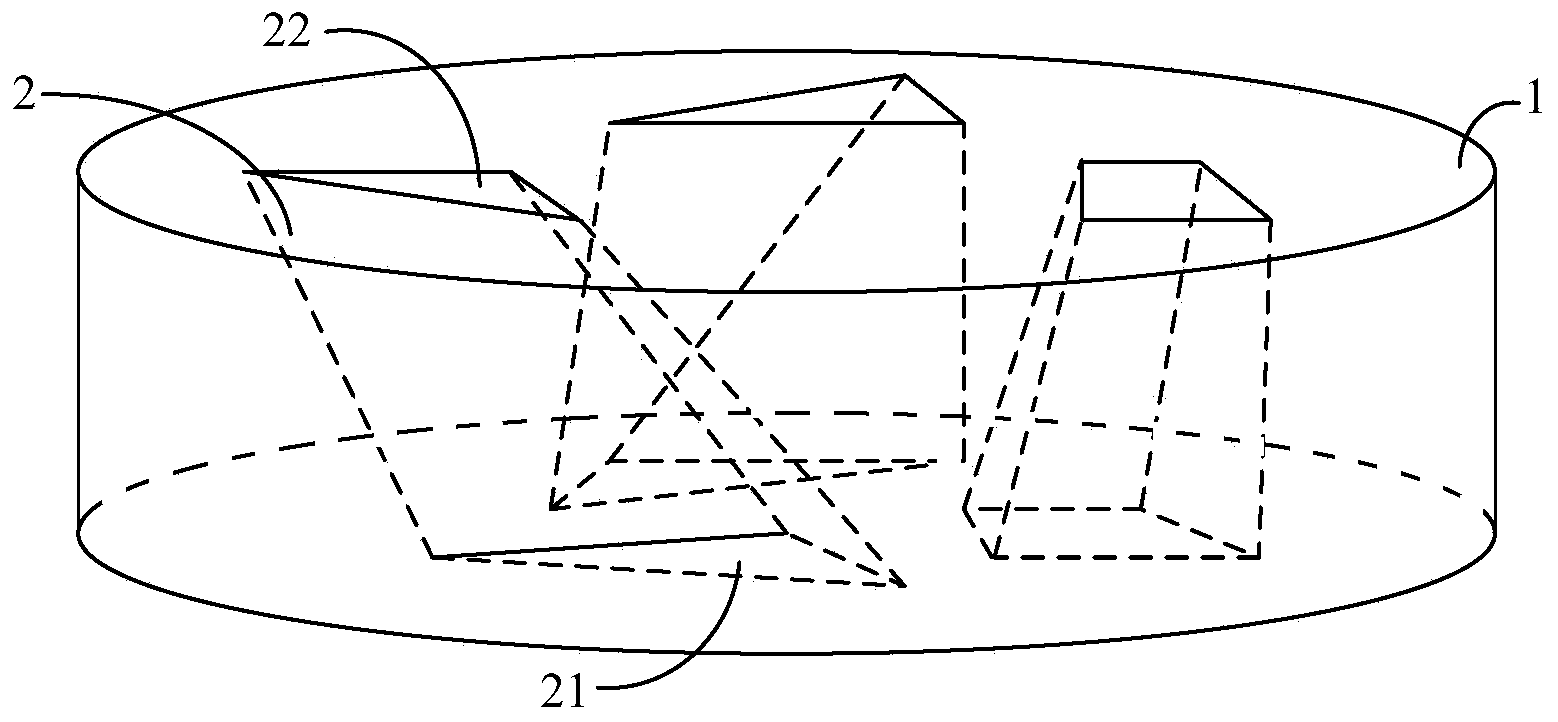

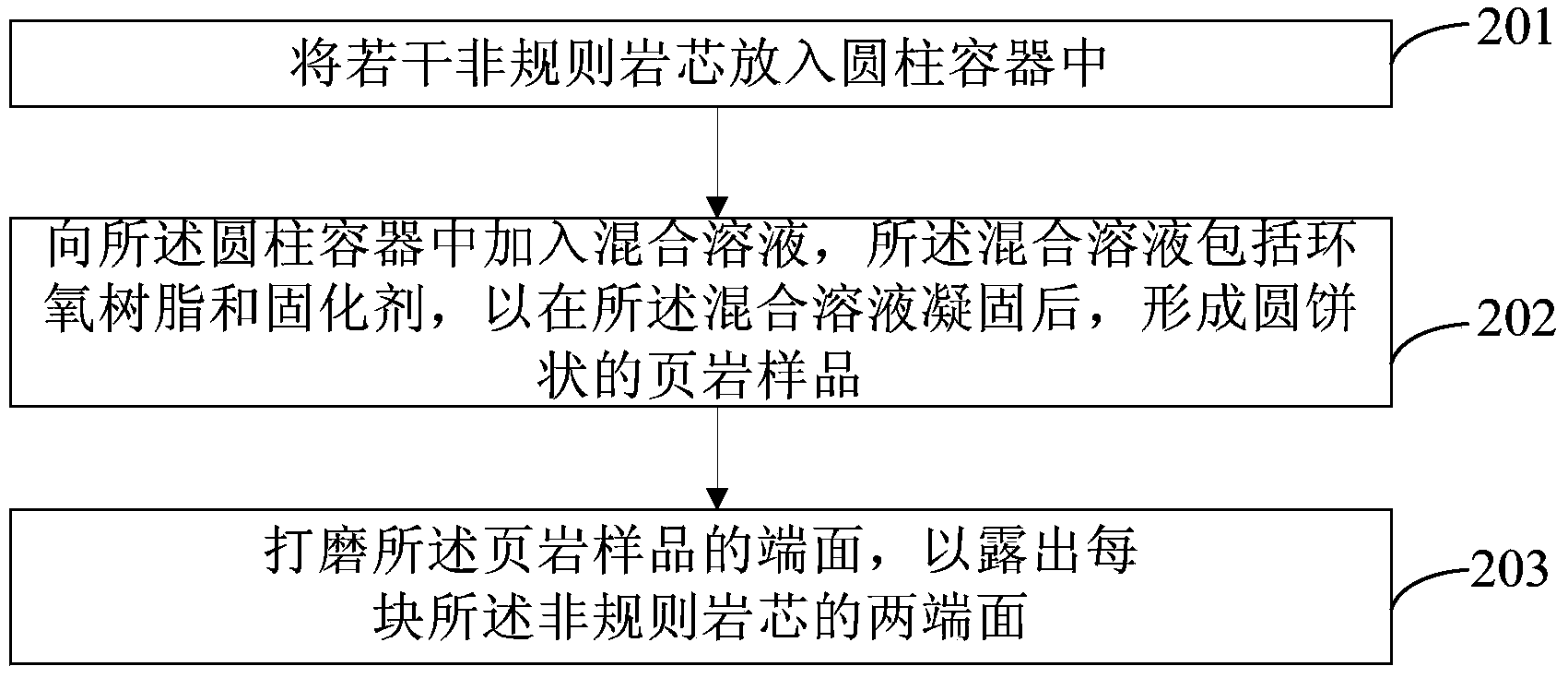

[0027] figure 2 A schematic flow chart of the irregular shale sample preparation method provided in Example 2 of the present invention, the irregular shale sample preparation method is used to prepare the irregular shale sample as described in Example 1, such as figure 2 As shown, the method includes:

[0028] 201. Put some irregular rock cores into a cylindrical container;

[0029] 202. Add a mixed solution into the cylindrical container, the mixed solution includes an epoxy resin and a curing agent, so that after the mixed solution is solidified, a disc-shaped shale sample is formed;

[0030] 203. Grinding the end faces of the shale samples to expose the two end faces of each irregular core.

[0031] Specifically, in practical applications, at least one irregular core can be selected, for example, it can be an irregular shale core. Mix epoxy resin and curing agent in a certain proportion to form a mixed solution, stir evenly and set aside. The container can be a paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com