High-stable and semi-flexible supporting structure for secondary lens of space camera

A support structure and space camera technology, applied in the field of aerospace optical remote sensing cameras, can solve the problems of poor static performance, large acceleration response multiple, low stiffness, etc., achieve high stiffness and small mass, eliminate influence, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The highly stable semi-flexible support structure for the secondary mirror of a space camera according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

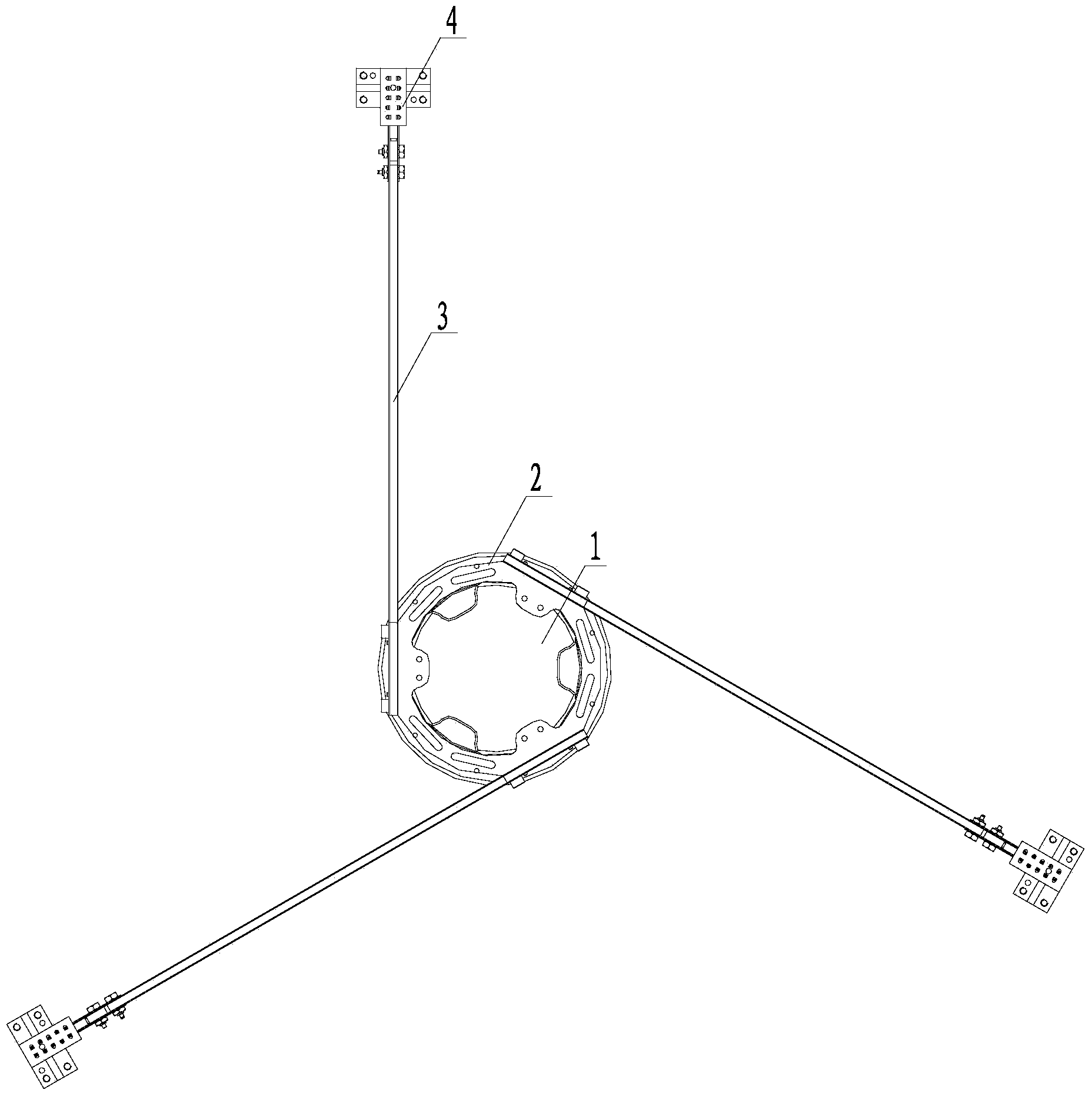

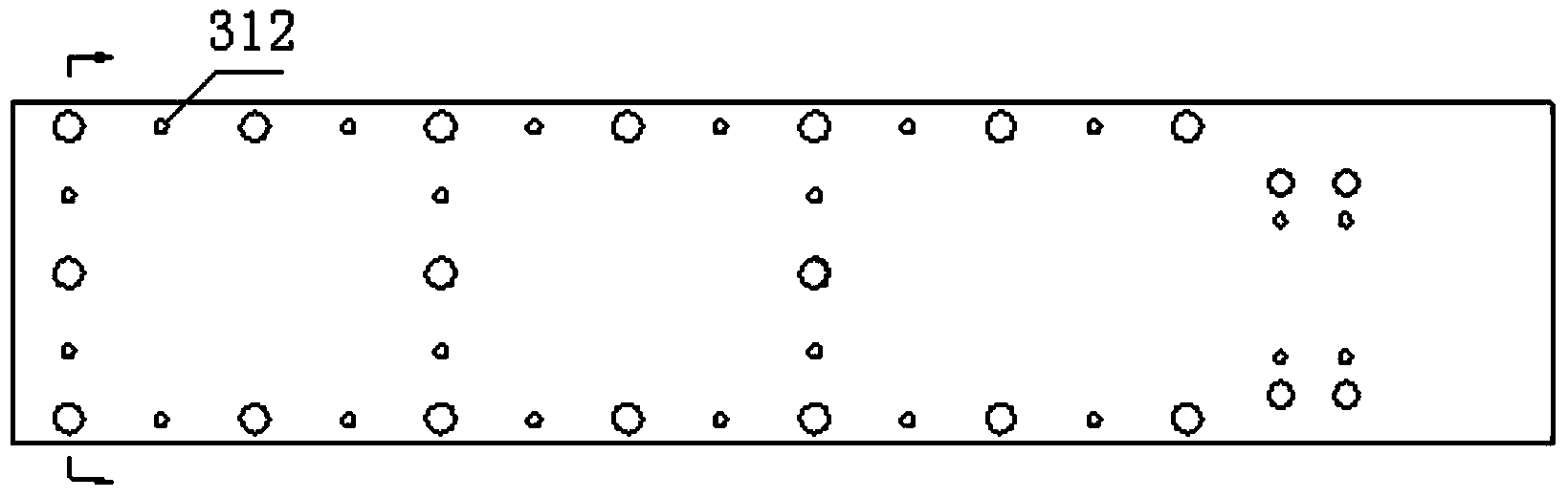

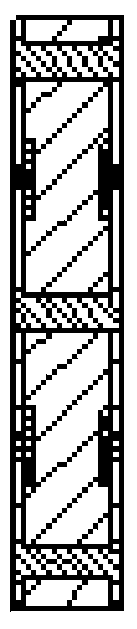

[0021] Such as Figure 1-Figure 7c As shown, the highly stable semi-flexible support structure for the secondary mirror of a space camera according to the present invention includes a secondary mirror support frame 2 , three support rods 3 , and three support seats 4 . Wherein, the secondary mirror support frame 2 is an annular frame, and the secondary mirror 1 is glued and fixed on the secondary mirror support frame 2 . Three support rods 3 are evenly distributed on the secondary mirror support frame 2, the first end of each support rod 3 is fixed on the secondary mirror support frame 2 along the tangential direction of the secondary mirror 1, and the three support rods 3 are positioned on the secondary mirror 1 The back of the reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com