Spiral contact voltage regulator

A contact voltage regulator, spiral technology, applied in the direction of transformers, variable transformers, inductors, etc., can solve the problems of temperature rise, large loss, short service life, etc., to achieve reliable contact, reduce loss, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with accompanying drawing:

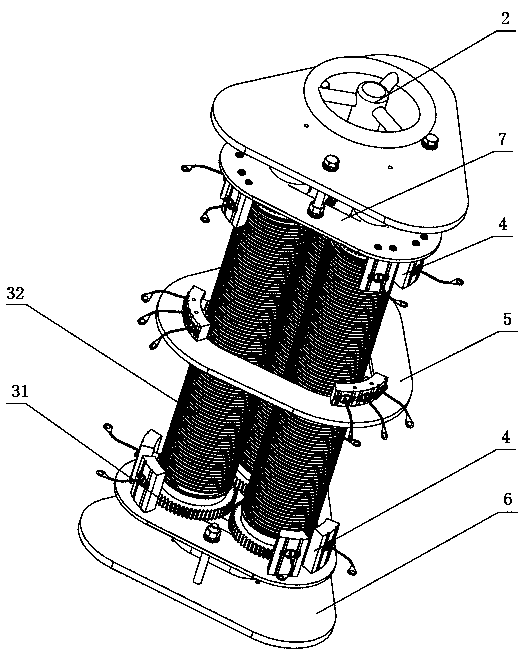

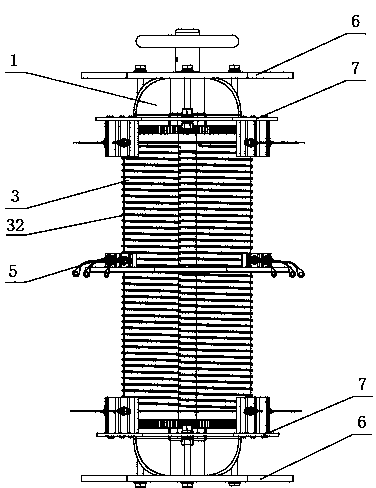

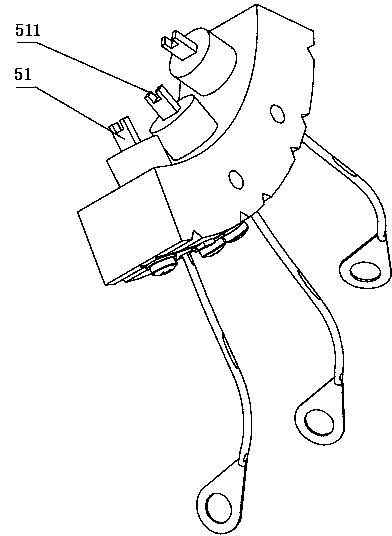

[0029] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The present invention includes a bracket, an iron core 1, a coil bobbin 3 sheathed outside the iron core 1, and a coil 32 spirally wound on the coil bobbin 3. The coil bobbin 3 is installed on the bracket and constitutes an axial limit and a circumferential To rotatably cooperate, the operating mechanism that drives the coil skeleton 3 to rotate is also provided on the bracket, and the fixed brush holder 4 is installed on the bracket, and the fixed brush holder 4 is provided with a fixed brush 41, and the fixed brush 41 Located on one side of the bobbin 3 and in close contact with the peripheral side of the coil 32, the coil 32 is also provided with a movable brush holder 5, and the movable brush holder 5 is provided with a movable brush 51, the movable brush The brush head of 51 is provided with a chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com