Low-voltage motor slot insulation structure

A low-voltage motor and slot insulation technology, which is applied in the field of motor components, can solve the problems of affecting the quality of the motor, scratches, and high hardness, and achieve the effects of reducing the probability of breakdown between turns of the motor, improving the ease of operation, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

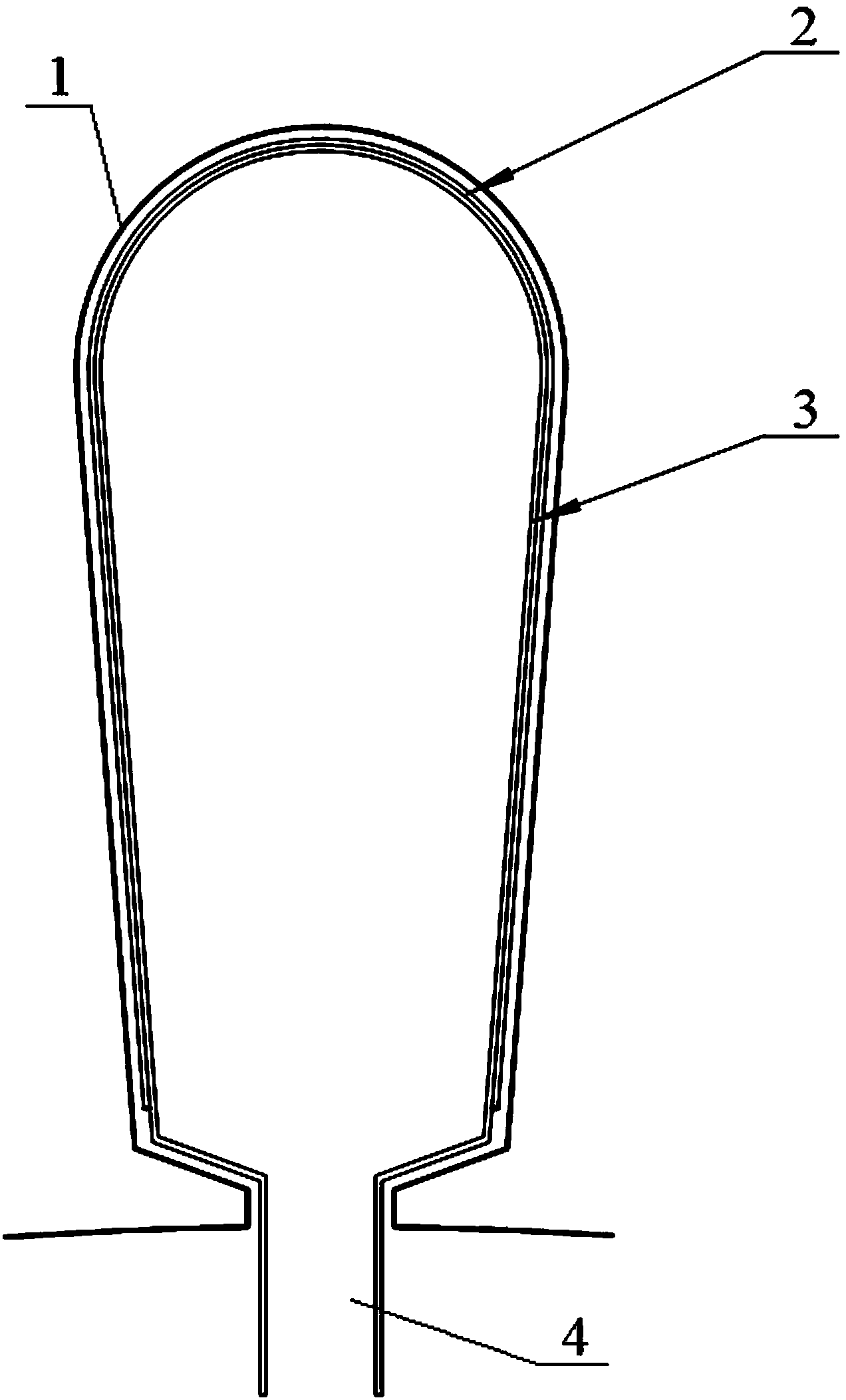

[0012] see figure 1 , a low-voltage motor slot insulation structure, including a slot body 1, along the inner wall of the slot body 1, a first layer of insulating paper 2 and a second layer of insulating paper 3 with the same thickness are sequentially arranged, and the two layers of the second layer of insulating paper 2 The ends respectively extend from the notch of the tank body 1, and the magnet wire guide opening 4 is formed between the two ends of the second layer of insulating paper 3.

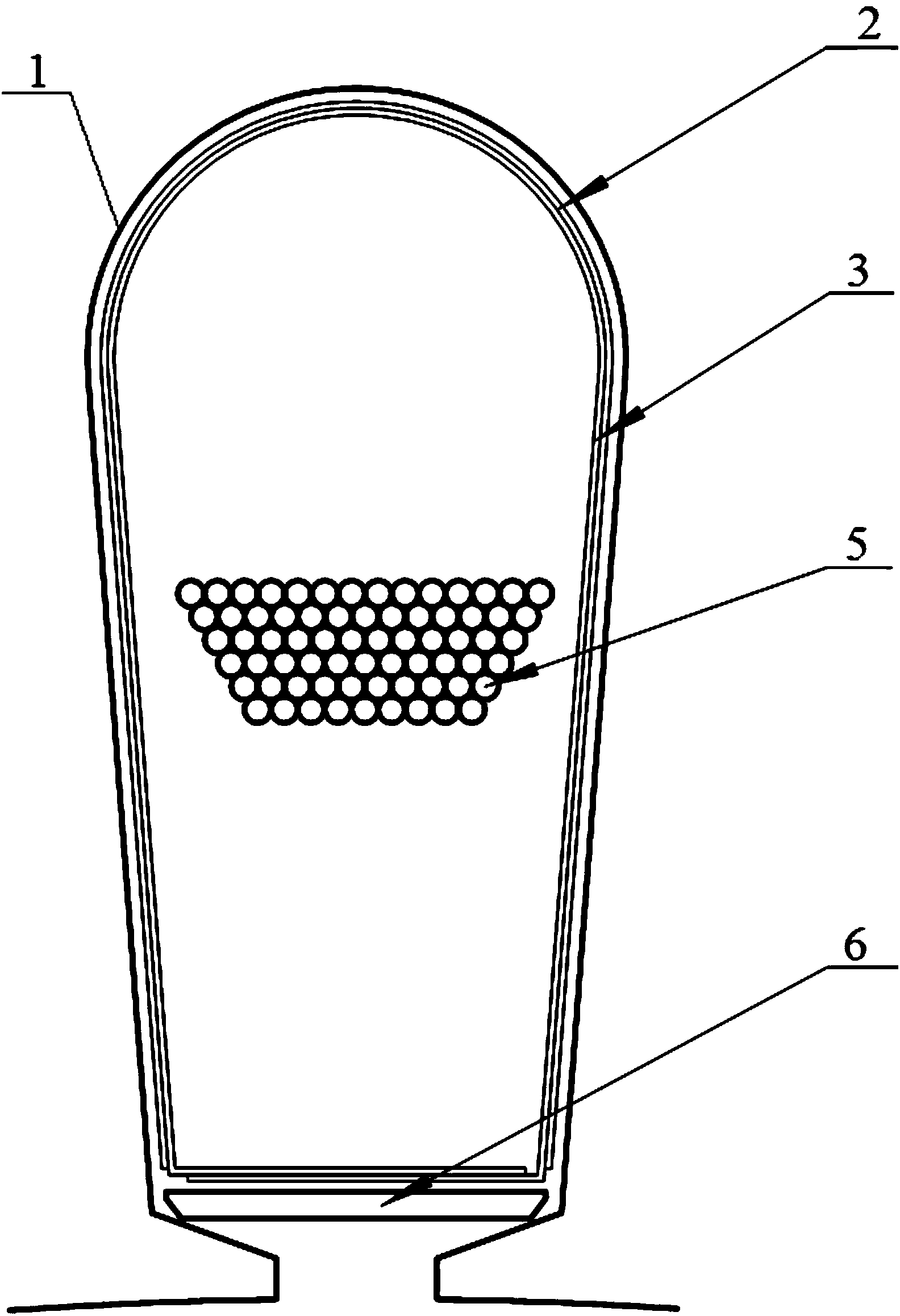

[0013] see figure 2 After inserting the magnet wire 5 into the groove body 1 along the magnet wire guide port 4, use a special tool to cut off the end of the redundant second layer of insulating paper 3, that is, to make the magnet wire guide port 4, the second The two ends of the layers of insulating paper 3 meet together on the inside of the notch of the tank body 1 , and then insert the slot wedge 6 inside the notch of the tank body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com