Cage Induction Rotor Core Transposition Speed Regulation Method

A rotor core and cage-type technology, which is applied in the field of AC speed control transmission, can solve the problem of not being able to drive the load with stepless speed control, etc., and achieve the effect of excellent soft start function, cost reduction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

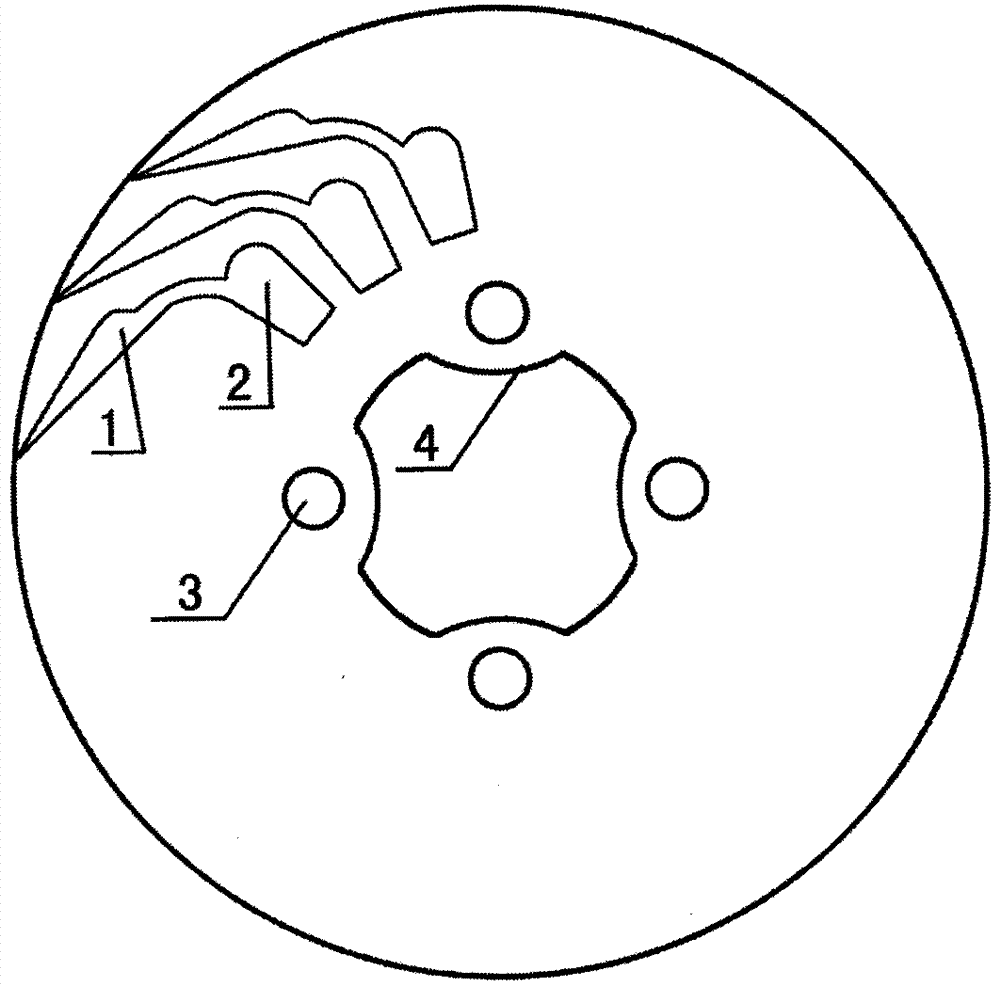

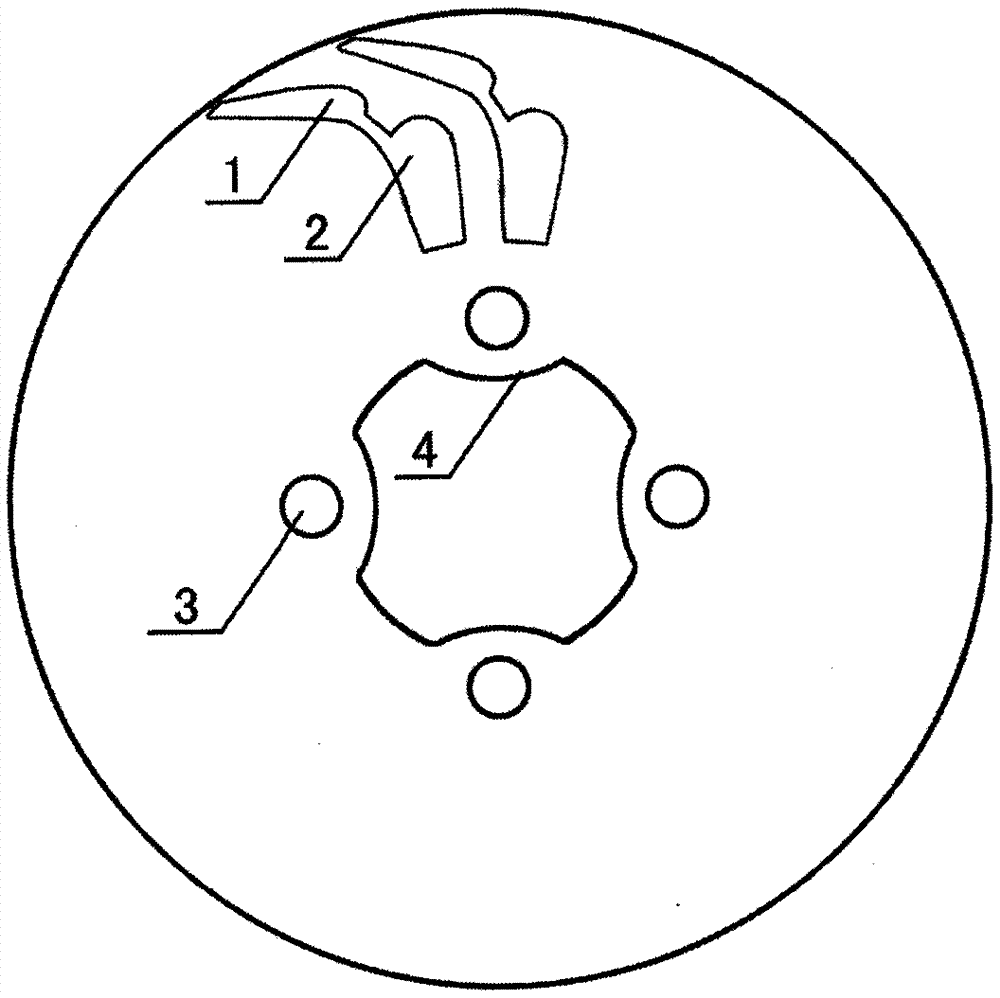

[0019] The rotor core is stacked and fixed on multiple axial connectors by lamination of the large bird-shaped rotor groove silicon steel punching bird head in the positive direction. The length is 0.9 stator core length, which can make the The bird's head of the long laminations and punched sheets that induce positive AC potential on the rotor bar is reversely laminated and fixed on the axial connector, so that the rotor bar embedded in the bird's body part with slot insulation in the lower half slot The short laminations that induce reverse AC potential are composed of short laminations. The rotor core is 40% longer than the stator core and can slide axially on the axial guide groove on the surface of the middle section of the rotor shaft so that the forward and reverse laminations are in the stator. An independent integral rotor core with the inner side of the core transposed and transmitting torque. When the long laminations that induce positive AC potential on the rotor g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com