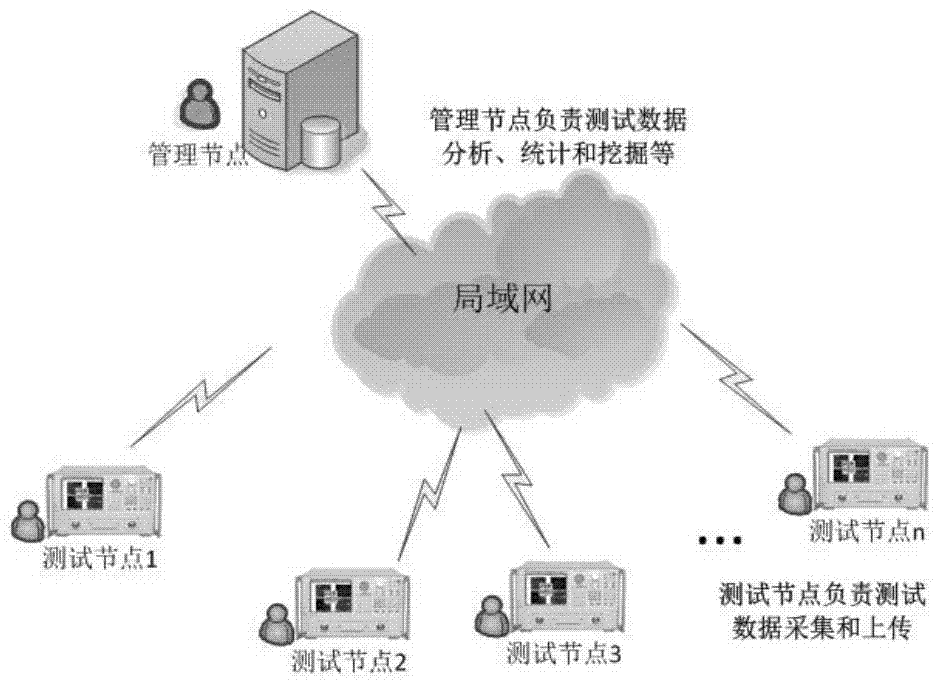

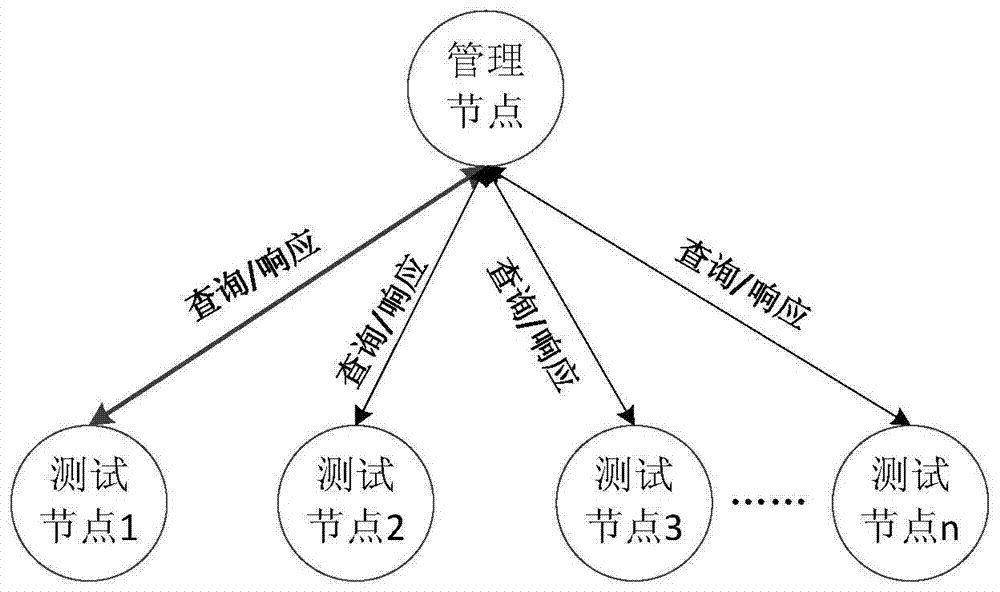

Multi-test node status monitoring system and method for component production line

A node state and node testing technology, applied in electrical components, transmission systems, digital transmission systems, etc., can solve problems such as insufficient scalability, poor real-time performance, and complex configuration, and achieve good scalability, small resource occupation, real-time strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

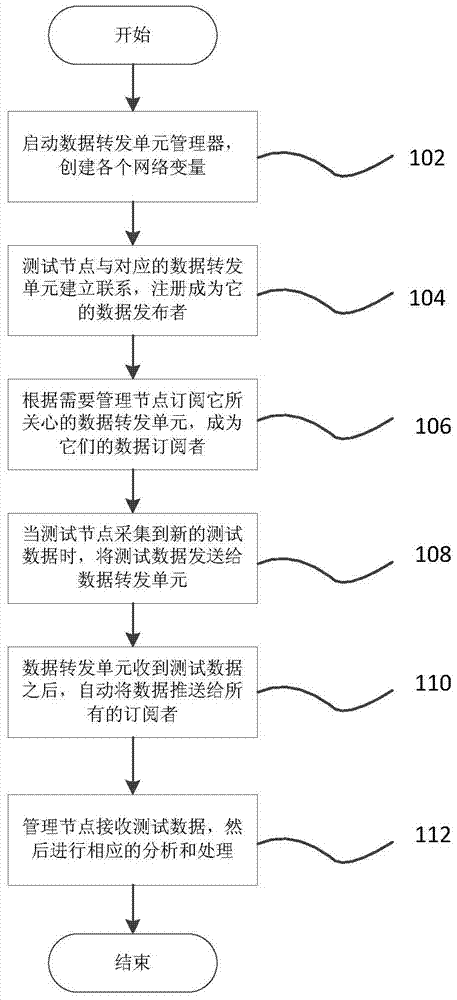

[0044] A multi-test node state monitoring method for a component production line, the method flow chart is shown in image 3 shown, including:

[0045] Step 102: start the data forwarding unit manager, and create each data forwarding unit;

[0046] Step 104: The test node establishes a connection with the corresponding data forwarding unit, and the test node registers as a data publisher of the data forwarding unit;

[0047] Step 106: The management node subscribes to the data forwarding unit concerned by the management node as needed, and becomes a subscriber of the corresponding data forwarding unit;

[0048] Step 108: When the test node collects new test data, send the test data to the data forwarding unit;

[0049] Step 110: After the data forwarding unit receives the test data, it automatically pushes the data to all management nodes;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com