Recoil square die

A mold and punching technology, applied in the direction of perforation tools, manufacturing tools, safety equipment, etc., can solve problems such as the impact of processing efficiency, hidden dangers to the safety of workers, and increase the time for replacing parts, so as to improve processing efficiency and save material change time. , high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

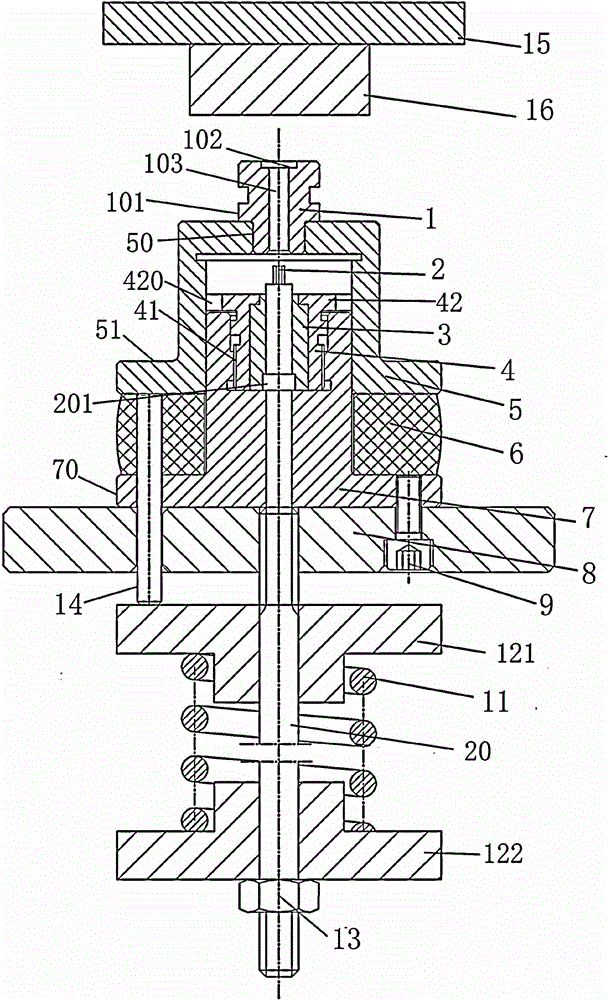

[0016] The embodiment of recoil square mold of the present invention: as figure 1Shown, comprise upper die 15 and lower die 8 that are arranged correspondingly up and down, lower die 8 is fixed on the punch workbench, the lower surface of upper die 15 is provided with pressure head 16, and upper die 15 can be driven to The stamping action is carried out below, and the punch 2 is fixed on the lower mold 8. The punch 2 includes a stamping part for contacting with the bolt to be processed and a support rod part 20 located below the stamping part. The punch 2 is fixed on the lower mold 8. , the lower mold 8 is also guided and slidably equipped with a fixing device in the up and down direction, and the fixing device is provided with a bolt installation channel for installing bolts that penetrates up and down. The bolt installation channel corresponds to the punch 2 up and down, and has an upper opening and The lower opening, the upper opening is used for loading bolts, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com