Paper sheet cutting and polishing device

A technology for cutting and grinding paper, applied in the direction of grinding machines, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problem of cutting fingers and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

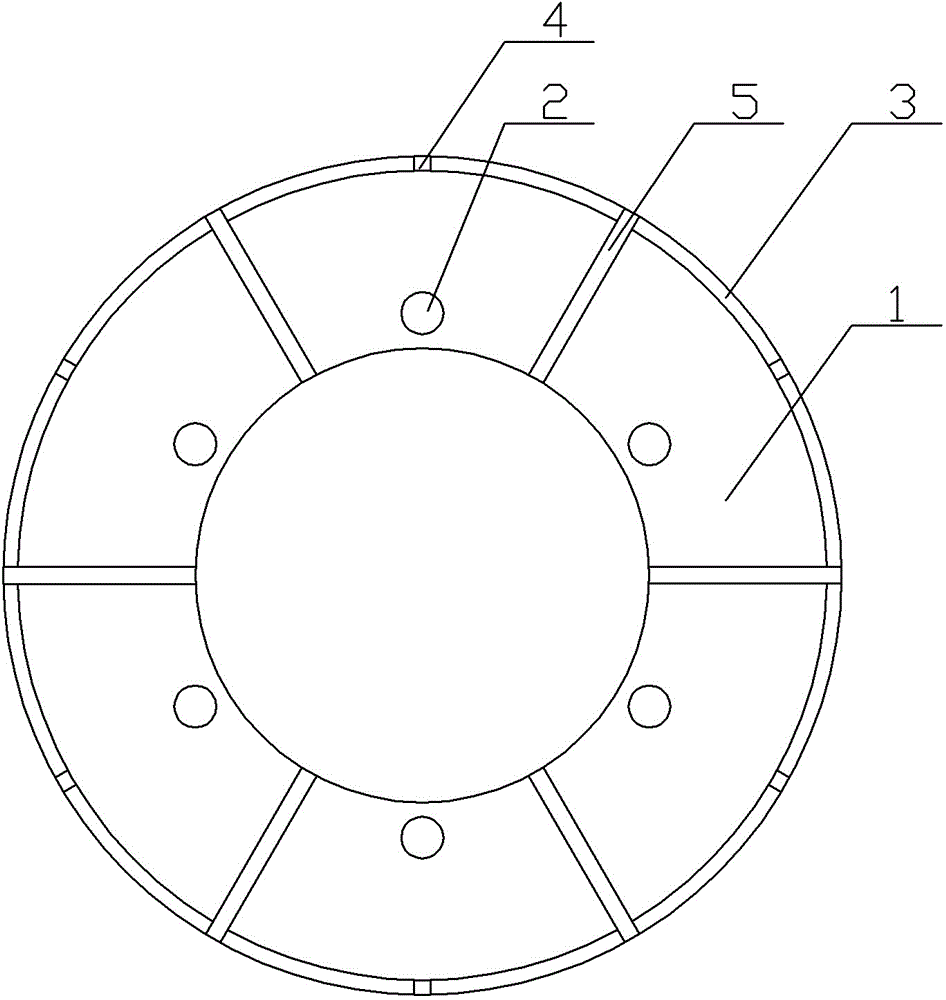

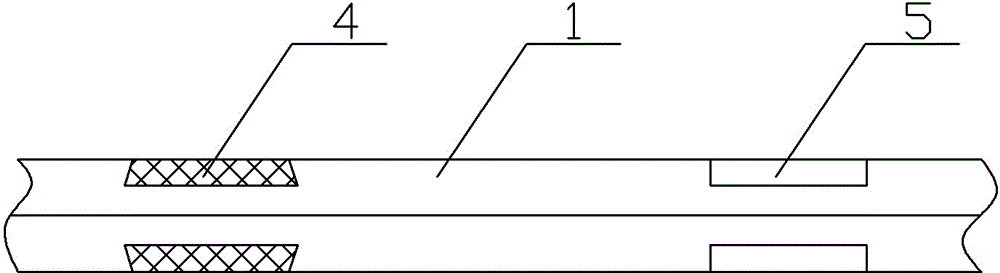

[0013] The reference signs in the accompanying drawings of the specification include: cutting knife 1 , bolt fixing hole 2 , blade portion 3 , grinding groove 4 , and chip collecting groove 5 .

[0014] The paper cutting and grinding device of the embodiment is as attached figure 1 and figure 2 As shown: it includes a circular cutting knife 1, the inner edge of the cutting knife 1 is provided with a bolt fixing hole 2, and is fixed on the cutting shaft through the bolt and the bolt fixing hole 2, and the outer edge of the cutting knife 1 is provided with a blade 3. The cutting knife 1 is provided with evenly spaced grinding grooves 4 and chip collecting grooves 5. The grinding grooves 4 and the chip collecting grooves 5 are symmetrically distributed on both sides of the cutting knife 1. The grinding groove 4 is filled with For abrasives with a flat surface, the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com