Fixing device used for rubber cutting and using method of fixing device

A fixing device and rubber technology, applied in the field of rubber processing, can solve the problems of affecting the cutting quality, the cutting machine is not labor-saving, etc., and achieve the effect of ensuring the cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

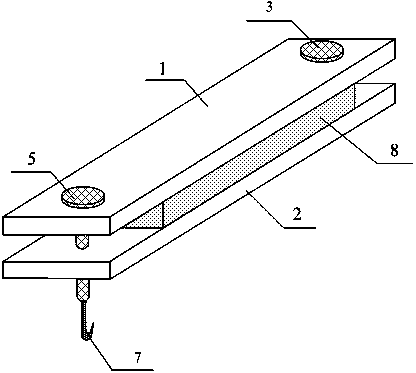

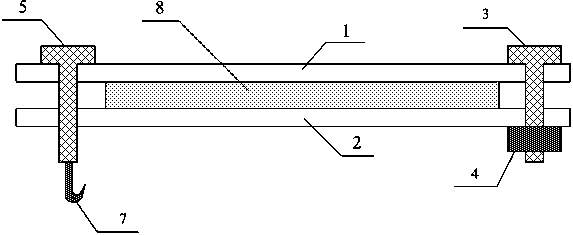

[0025] Embodiment one, figure 1 A schematic structural view of the first fixing device for rubber cutting of the present invention is shown, figure 2 A schematic cross-sectional view of the first fixing device for rubber cutting of the present invention is shown. The fixing device for rubber cutting is characterized in that it comprises: an upper splint 1, a lower splint 2, a first rivet 3, a nut 4, a second rivet 5 and a hook 7; There is a hole matched with the first rivet 3, the first rivet 3 passes through the holes of the upper splint 1 and the lower splint 2, the lower end of the first rivet 3 cooperates with the nut 4; the left end of the upper splint 1 and the lower splint 2 is provided with a The second rivet 5 fits through the holes of the upper splint 1 and the lower splint 2 , and the lower end of the second rivet 5 is connected with the hook 7 . After determining the cutting size of the cutting material 8, the processing personnel add a heavy object to the hook ...

Embodiment 2

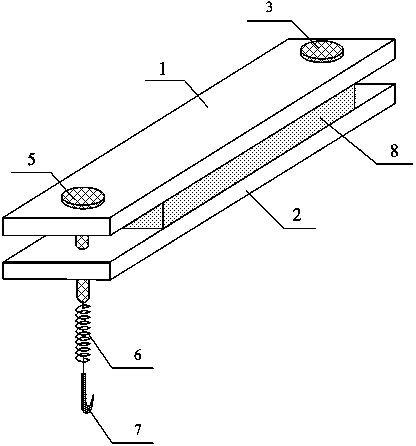

[0034] Embodiment two, image 3 A schematic cross-sectional view of the second fixing device for rubber cutting of the present invention is shown. The fixing device for rubber cutting in the second embodiment is different from the fixing device for rubber cutting in the first embodiment in that it includes: the lower end of the second rivet 5 is connected to one end of the spring 6, and the other end of the spring 6 is connected to the hook 7 connect.

[0035] The using method of the fixing device for rubber cutting provided in the second embodiment is different from the first embodiment in that:

[0036] Step 102 , pull down the spring to let the hook hang on the ground or a heavy object on the ground, so that the upper splint 1 and the lower splint 2 clamp the cutting material 8 .

[0037] Step 104, pull down the spring to unhook the hook, loosen the upper splint 1, and translate the cutting material 8 at the same time to determine the next cutting width, and then cycle th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap