Production method for cutting and vulcanizing plant fiber elastic material

A technology of elastic materials and plant fibers, applied in chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve problems such as collapse, inconsistent mechanical properties of elastic materials, and bulges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

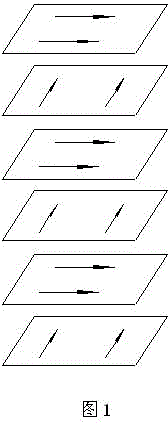

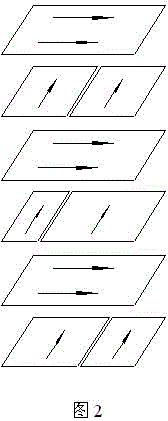

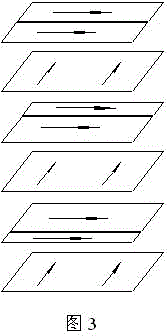

[0021] Embodiment 1 of the present invention. The plant fiber elastic material cutting and vulcanization production method is to produce plant fiber elastic sheets according to the prior art. The direction of the elastic sheet produced along the production line is regarded as the longitudinal direction, and the direction of the elastic sheet perpendicular to the production line is regarded as the horizontal direction. Rotate 90 degrees to get a transverse elastic sheet, such as figure 1 As shown, the longitudinal elastic sheet and the transverse elastic sheet of the whole block are produced and cut respectively, then the longitudinal elastic sheet and the transverse elastic sheet are stacked, and the stacked elastic sheets are heat-pressed, and then the elastic The material is cut and trimmed, vulcanized and packaged to obtain elastic material.

[0022] The leftovers obtained by cutting and trimming after hot pressing can repair the defects of the elastic sheet. Tear off the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com