High-temperature superconducting cable and joint connecting method thereof

A high-temperature superconducting and cable joint technology, which is applied in the direction of conductive connection, superconducting devices, welding/welding connection, etc., can solve the problems of poor joint stability, difficult processing, large joint volume, etc., and the length requirement is small , solve the effect of limited length and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

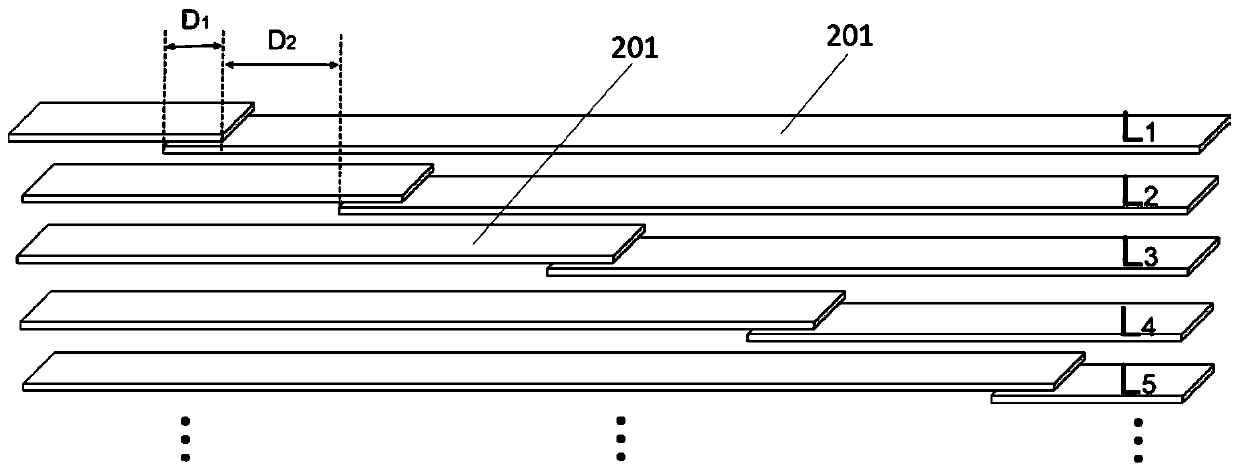

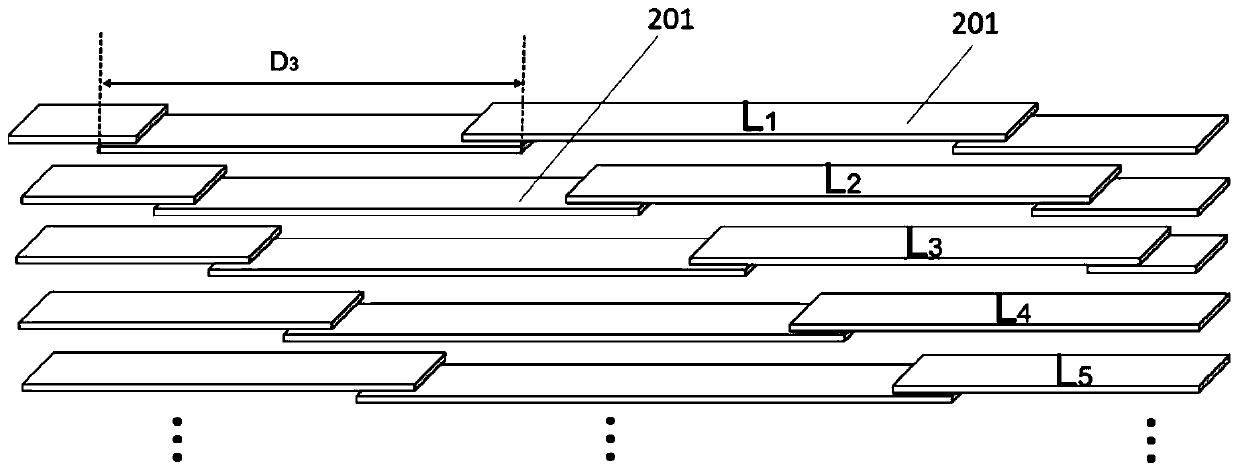

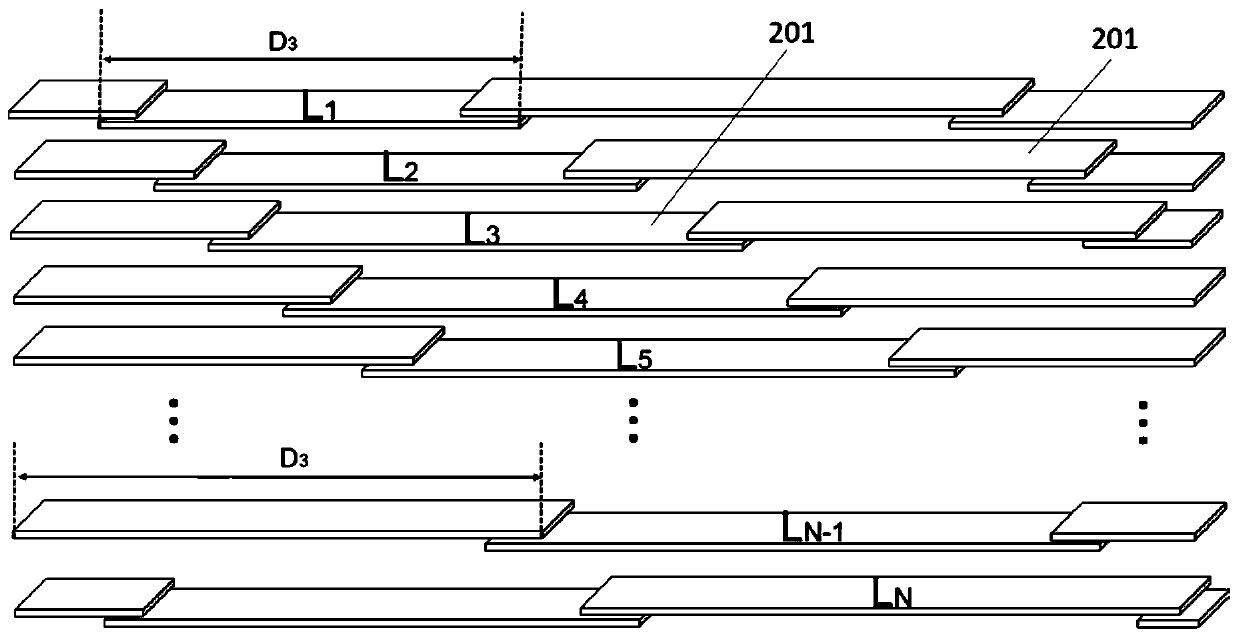

[0039]Because the lengths of high-temperature superconducting strips produced by high-temperature superconducting strip manufacturers vary from a few meters to several hundred meters, the longest mass-produced strips are basically more than 100 meters in length. If the cable is processed first, only strips of the same length can be used, which are basically more than 100 meters in length. As a result, the strips produced by the manufacturer have a lot of waste. If they are short, they cannot be used, and if they are long, they need to be cut off. A joint needs to be processed every 100 meters, and the size of the joint is much larger than the size of the cable, resulting in uneven cables and difficult coil winding. This embodiment provides a new high-temperature superconducting cable joint method. In the high-temperature superconducting cable joint connection method, the large joint of the traditional cable is changed into a joint of a single strip and evenly distributed in the...

Embodiment 2

[0057]An embodiment of the present invention discloses a high-temperature superconducting cable, which is connected based on the cable joint connection method in Embodiment 1. The high-temperature superconducting cable includes: a high-temperature superconducting stack 2, a high-temperature superconducting cable The superconducting stack 2 is set by stacking multiple single-layer long strips; the single-layer long strip is formed by stacking and welding multiple high-temperature superconducting strips 201 in sequence, and the welding points of two adjacent single-layer long strips It is arranged at intervals in the horizontal direction; it also includes a binding piece 3 that binds a plurality of stacked single-layer long strips into a high-temperature superconducting stack 2 .

[0058] In order to improve the performance of the high-temperature superconducting cable, a layer of aluminum gasket 1 is provided on the upper and lower surfaces of the high-temperature superconductin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com