Agricultural unmanned helicopter

An unmanned helicopter and agricultural technology, applied in aircraft parts, fuselage frames, launchers, etc., can solve the problems of poor adjustment of the center of gravity of the fuselage, small maneuvering load carrying capacity, and low strength ratio, and achieve rapid adjustment of the machine. Center of gravity, enhanced carrying capacity, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

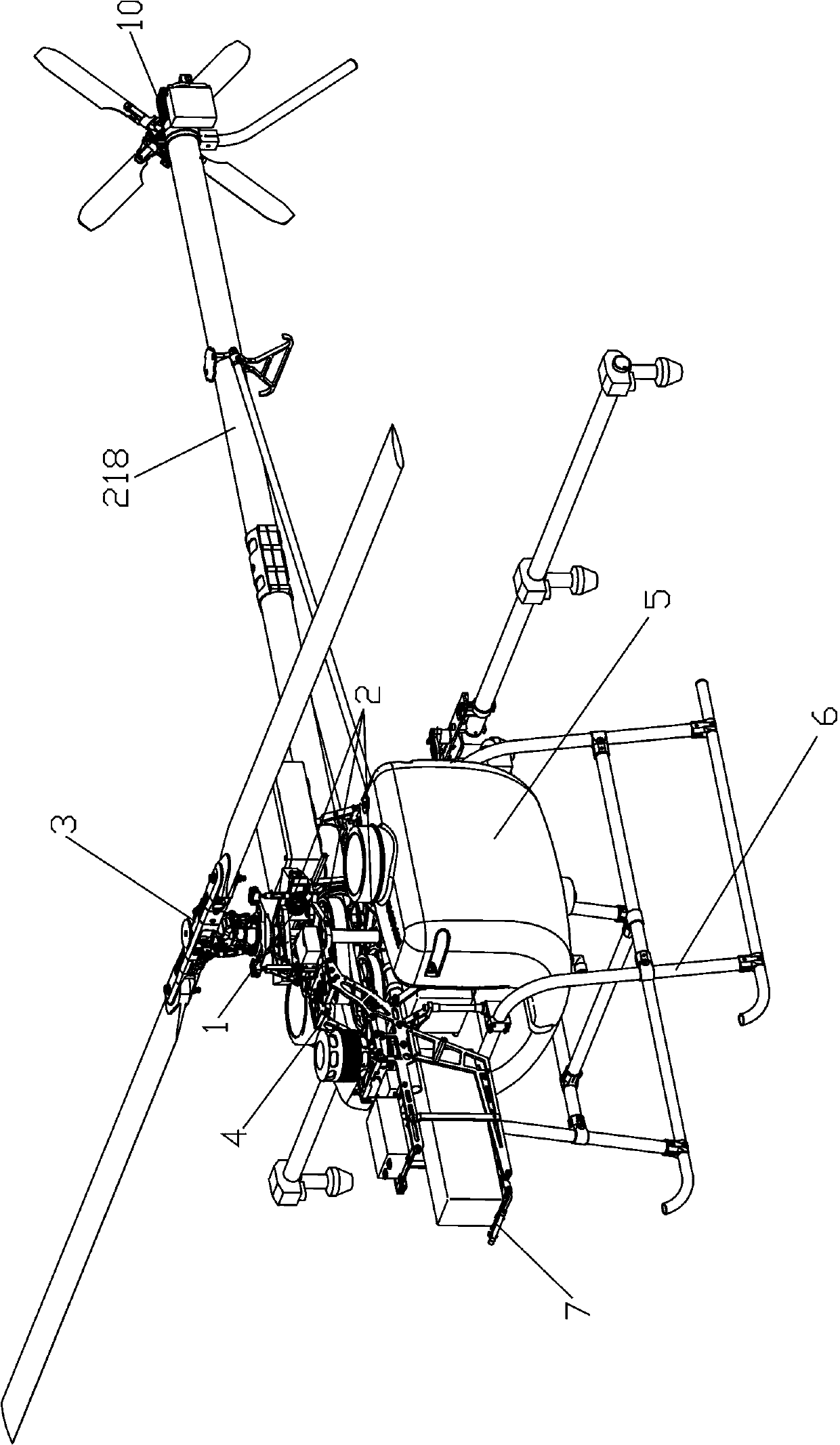

[0028] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

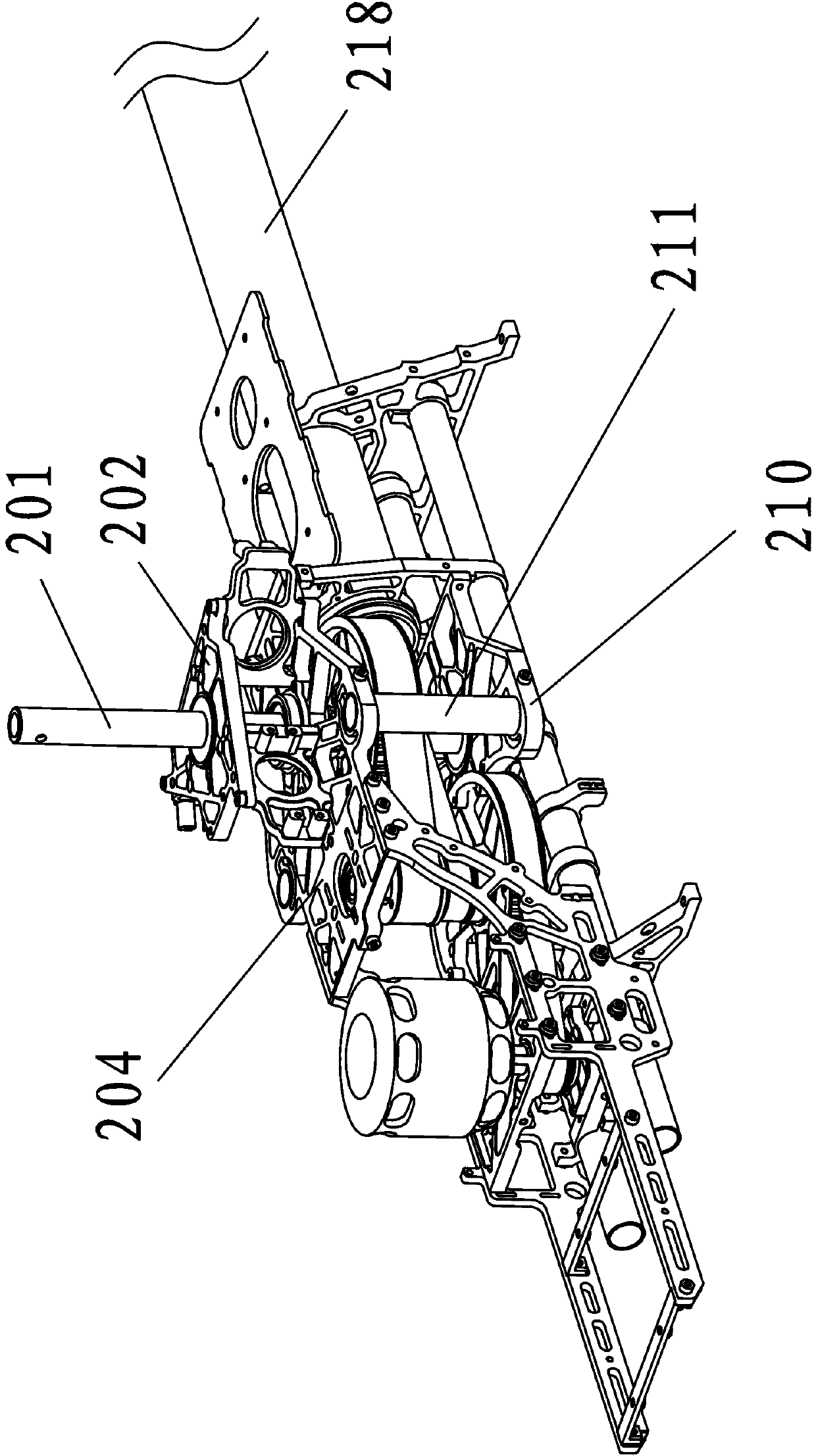

[0029] At present, due to structural design problems of the fuselage, agricultural unmanned helicopters have bottlenecks such as high cost, insufficient stability, and low matching between the fuselage and the load equipment, which have always restricted the wide application of unmanned helicopters at the industrial level. The present invention just improves this present situation, and invents a simple and firm fuselage body mechanism—a three-layer integrated frame, which solves the deficiencies in the prior art.

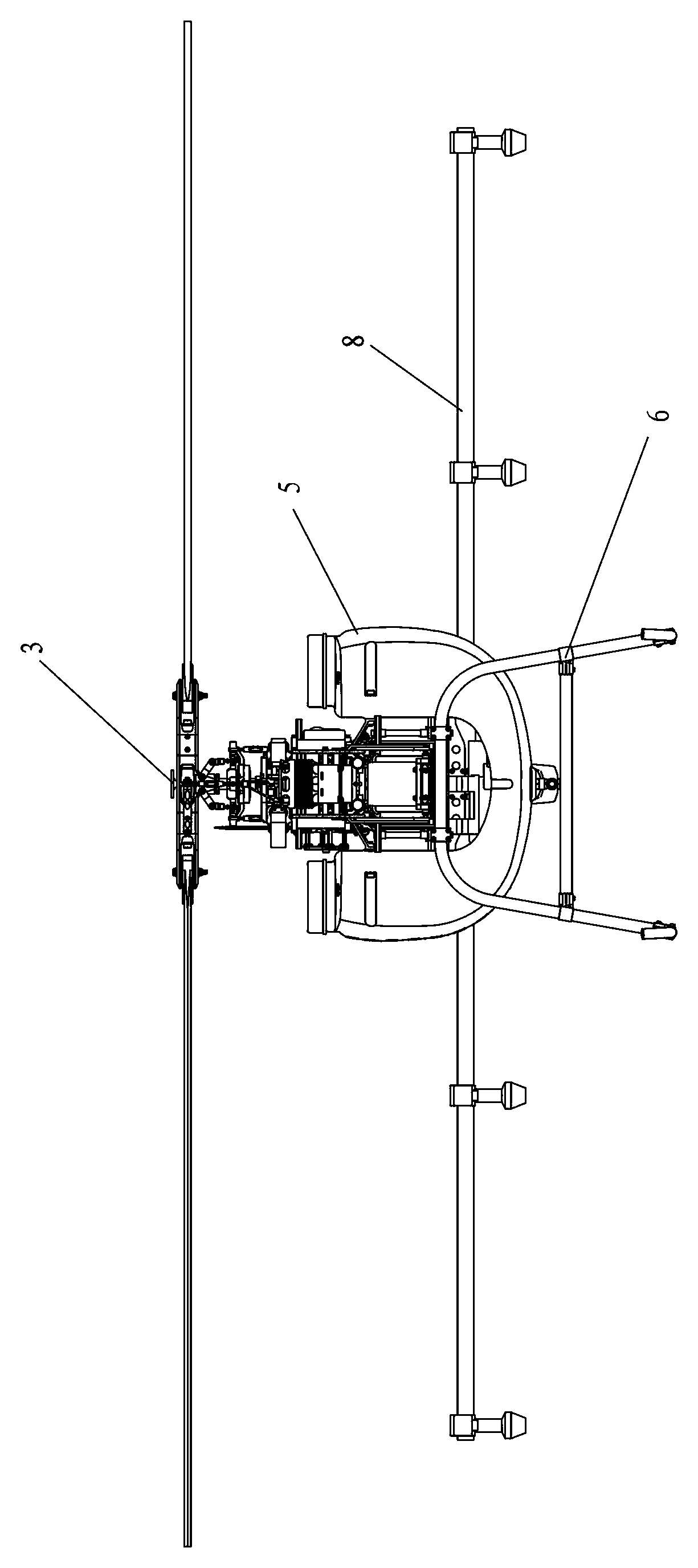

[0030] see Figure 1-Figure 4 , a kind of agricultural unmanned helicopter of the present invention, comprises fuselage body, and fuselage body comprises frame 2, and frame 2 is provided with the rotor head 3 that is used for fixing main rotor, and main rotor is installed in the large paddle clip of rotor head 3 It is driven by a brushles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com