Feeding device for circular cans

A technology of feeding device and round cans, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high equipment cost and low efficiency of manual transmission, and achieve the effect of low cost, simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

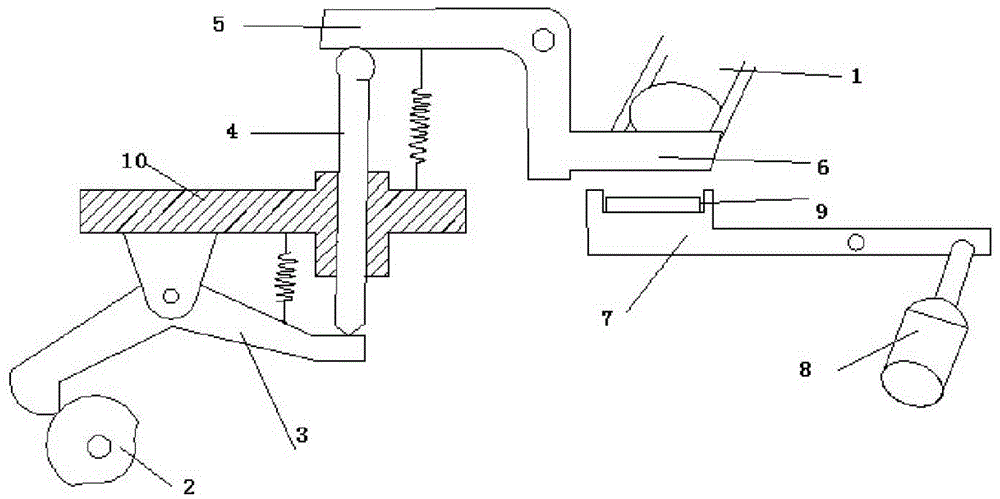

[0014] The reference signs in the description of the drawings are: storage tank 1, cam mechanism 2, lever type swing rod 3, push rod 4, "L" shaped rotating arm 5, baffle plate 6, rotary table 7, cylinder 8, assembly Clip groove 9, frame 10.

[0015] Such as figure 1 As shown, the technical solution provides a feeding device for round cans, including a frame 10, a storage tank 1, a control device and a steering device, and the storage tank 1 is an inclined chute. The control device includes a cam mechanism 2, a lever swing lever 3, a push rod 4, an "L" shaped rotating arm 5 and a baffle plate 6. Lever type swing bar 3 is " V " shape structure, and middle part is hinged on the frame 10 , the left end of lever type swing bar 3 is connected with the follower of cam mechanism 2 , and its right end is hinged with the lower end of push rod 4 . In addition, a tension spring is connected between the right end of the lever swing rod 3 and the frame 10 . A slide rail is vertically ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com