Cyclone mud-sand separation apparatus

A technology for sediment separation and sediment, which is applied in the field of sediment separation devices and cyclone sediment separation devices, can solve problems such as inappropriateness, and achieve the effect of improving applicability and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

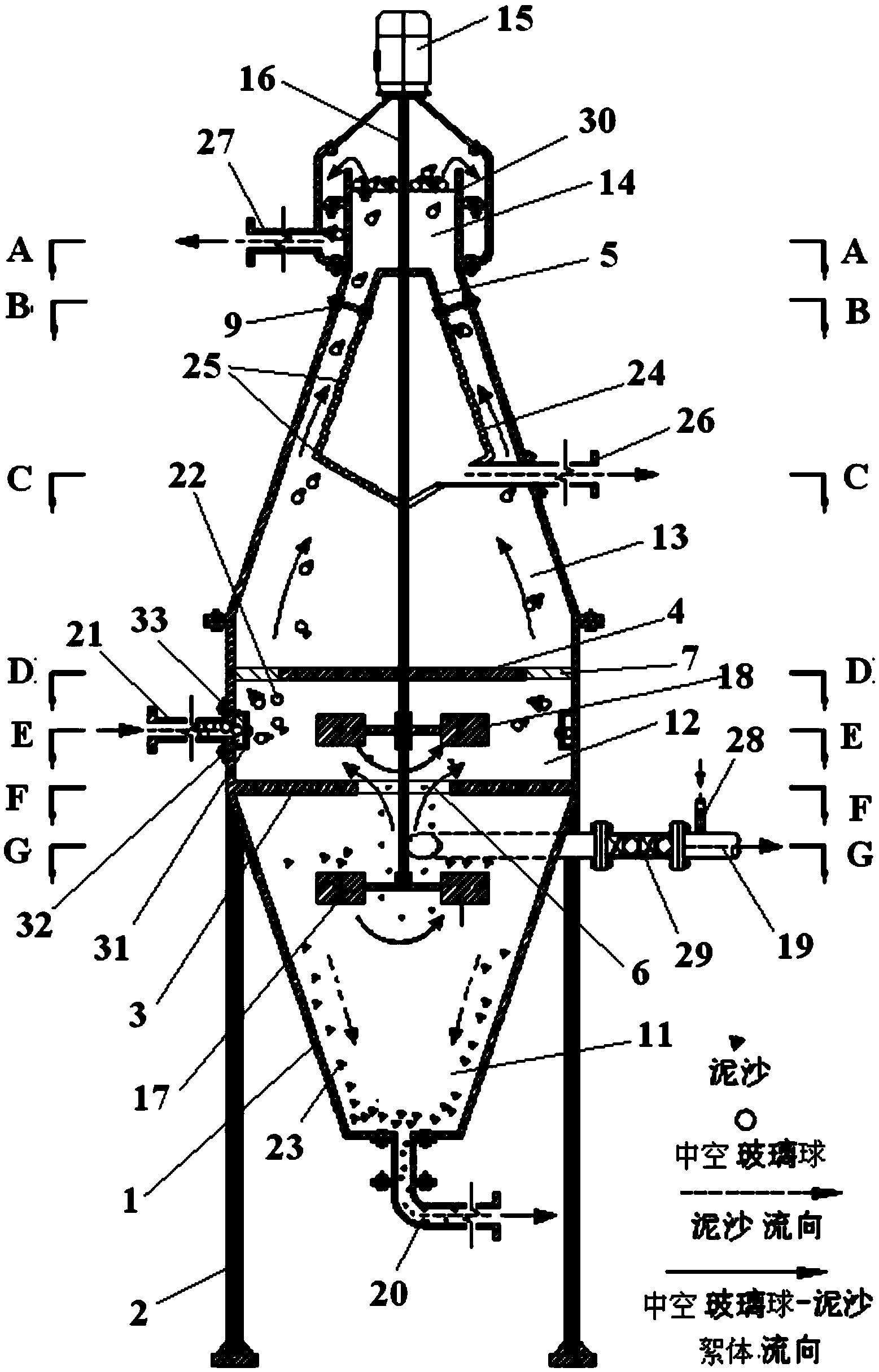

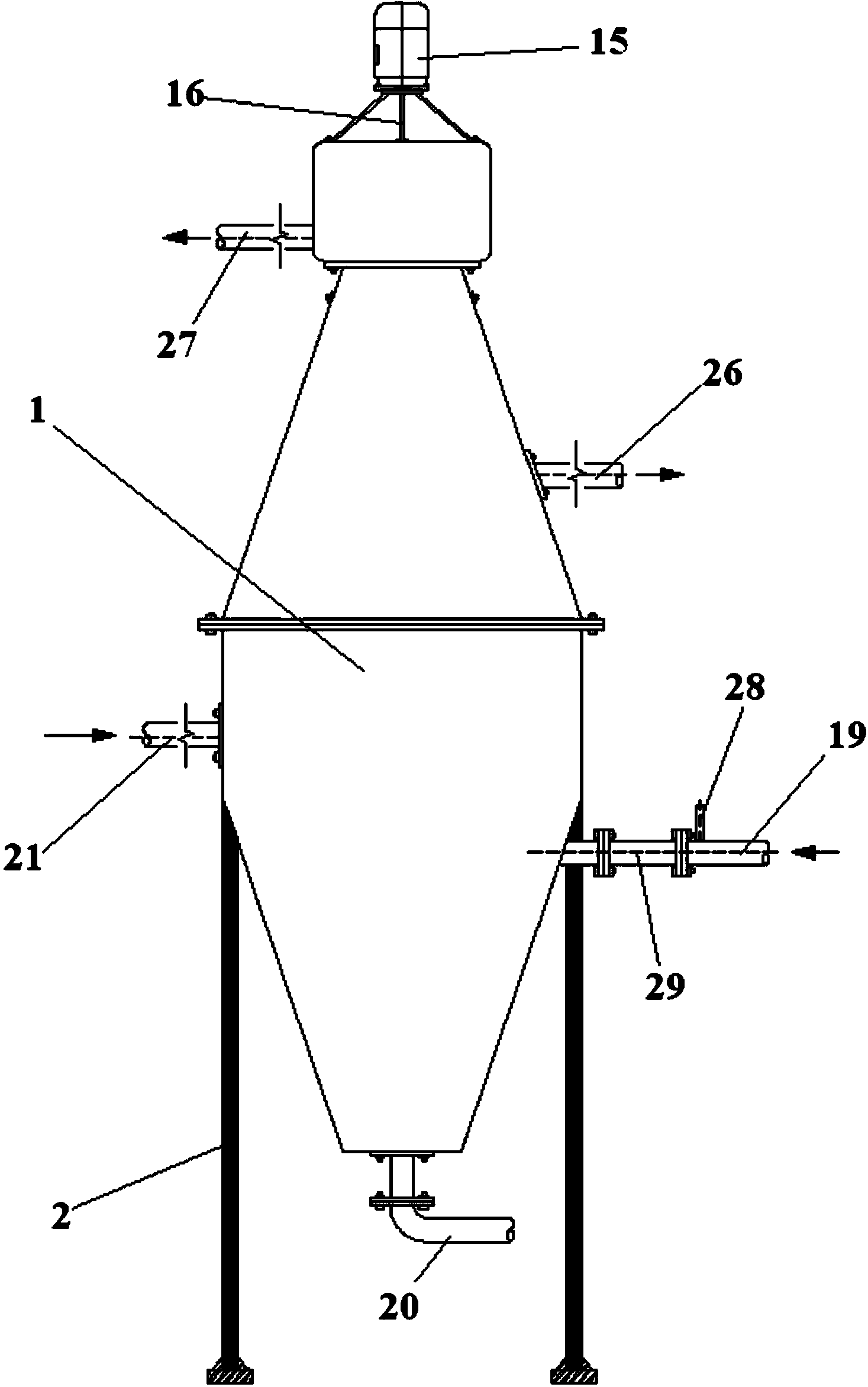

[0048] Follow the above technical solutions, such as Figure 1 to Figure 11 As shown, this embodiment provides a cyclone sediment separation device, including a base frame 2 on which a tank body 1 is fixed;

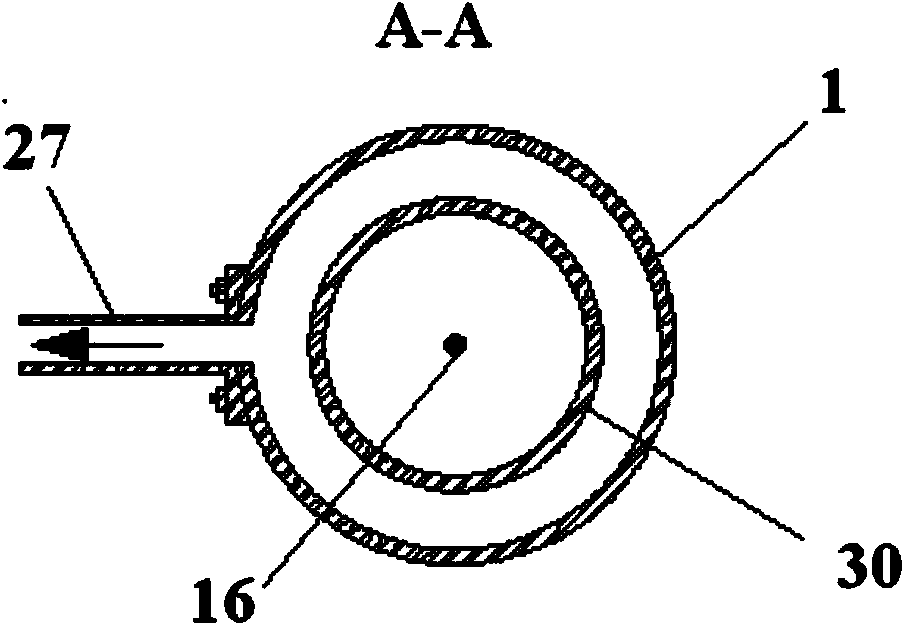

[0049] The said tank body 1 is successively installed with a sand baffle 3, a support plate 4 for installing the stirring shaft 16 and a fixing frame 5 for fixing the clear water collection cover 25 from bottom to top. The center of the sand baffle 3 The water through hole 6 is processed, the support plate 4 is fixed on the inner wall of the tank body 1 through the ribs 7, and the gap between the tank body 1 and the support plate 4 is divided into sector-shaped channels 8 by the ribs 7, and the fixing frame 5 passes through The connecting piece 9 is fixed on the inner wall of the tank body 1, and the connecting piece 9 uses bolts. The gap between the tank body 1 and the fixing frame 5 is divided into an overflow channel 10 by the connecting piece 9;

[0050] The sediment baff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com