Method for identifying bamboo fibers

A technology of bamboo fiber and bamboo pulp fiber, which can be applied in the direction of measuring device, material analysis by optical means, instrument, etc., can solve the problem of identifying less bamboo fiber and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Strong oxidant treatment of the cellulose fibers to be tested: use hydrogen peroxide as a strong oxidant, the treatment temperature is 90° C., the treatment time is 1 h, the hydrogen peroxide content is 5 g / L, and the bath ratio is 1:45.

[0024] (2) The treated fiber is made into a sample piece: ① Pulverize spectral-grade KBr in an agate mortar and grind it to a fine powder, dry it in a vacuum oven, and place it in a desiccator for use; ② Put the treated fiber Wash with water at 80°C until neutral, and dry in a vacuum oven for 16 hours to dryness; weigh 2 mg of fiber samples for drying, adjust the humidity for 24 hours, and grind to 2 μ; ③ Weigh 2 mg of fiber samples, and use 1 mg of samples to The ratio of 150mg KBr weighs dry KBr and pours it into an agate mortar and grinds it in a drying oven until the two are completely mixed; 13mm transparent sheet with a thickness of 0.8mm.

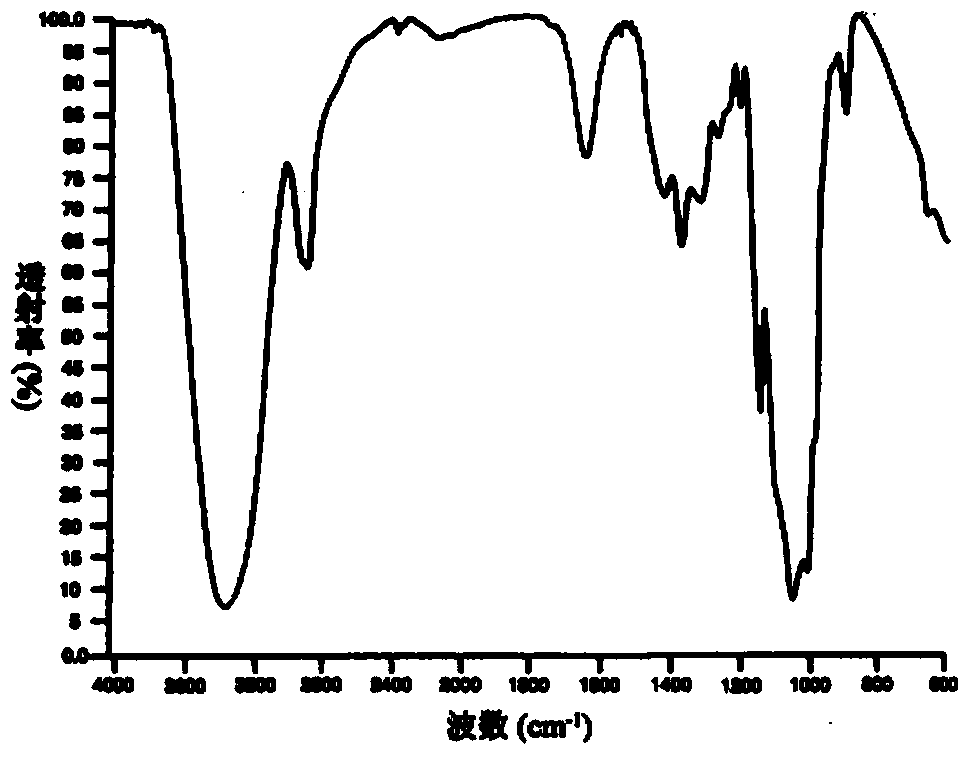

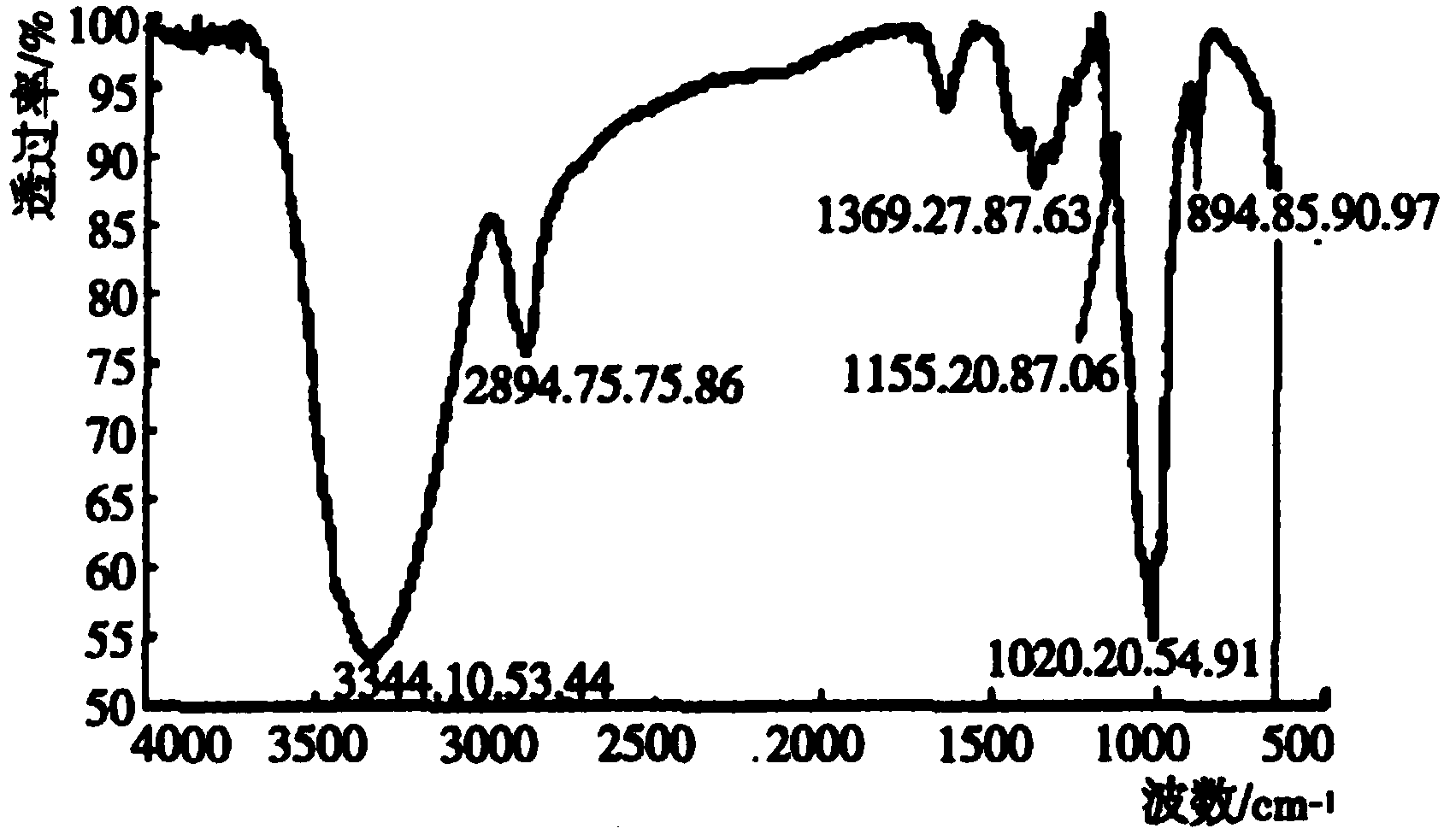

[0025] (3) Measure the infrared spectrogram of the sample piece on the infrared spe...

Embodiment 2

[0027] (1) Strong oxidant treatment of the cellulose fibers to be tested: use hydrogen peroxide as a strong oxidant, the treatment temperature is 90° C., the treatment time is 1 h, the hydrogen peroxide content is 5 g / L, and the bath ratio is 1:45.

[0028] (2) The treated fiber is made into a sample piece: ① Pulverize spectral-grade KBr in an agate mortar and grind it to a fine powder, dry it in a vacuum oven, and place it in a desiccator for use; ② Put the treated fiber Wash with water at 80°C until neutral, and dry in a vacuum oven for 16 hours to dryness; weigh 2 mg of fiber samples for drying, adjust the humidity for 24 hours, and grind to 2 μ; ③ Weigh 2 mg of fiber samples,

[0029] And weigh the dry KBr with the ratio of 1mg sample to 150mgKBr, pour it into an agate mortar and grind it in a drying oven until the two are completely mixed and uniform; A transparent sheet with a diameter of 13 mm and a thickness of 0.8 mm was made.

[0030] (3) Measure the infrared spectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com