Boiler chimney dust collection system and dust collection method

A dust removal system and chimney technology, applied in the field of dust removal, can solve the problems that the dust removal device cannot adjust the dust removal capacity, large investment, and does not meet the emission requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

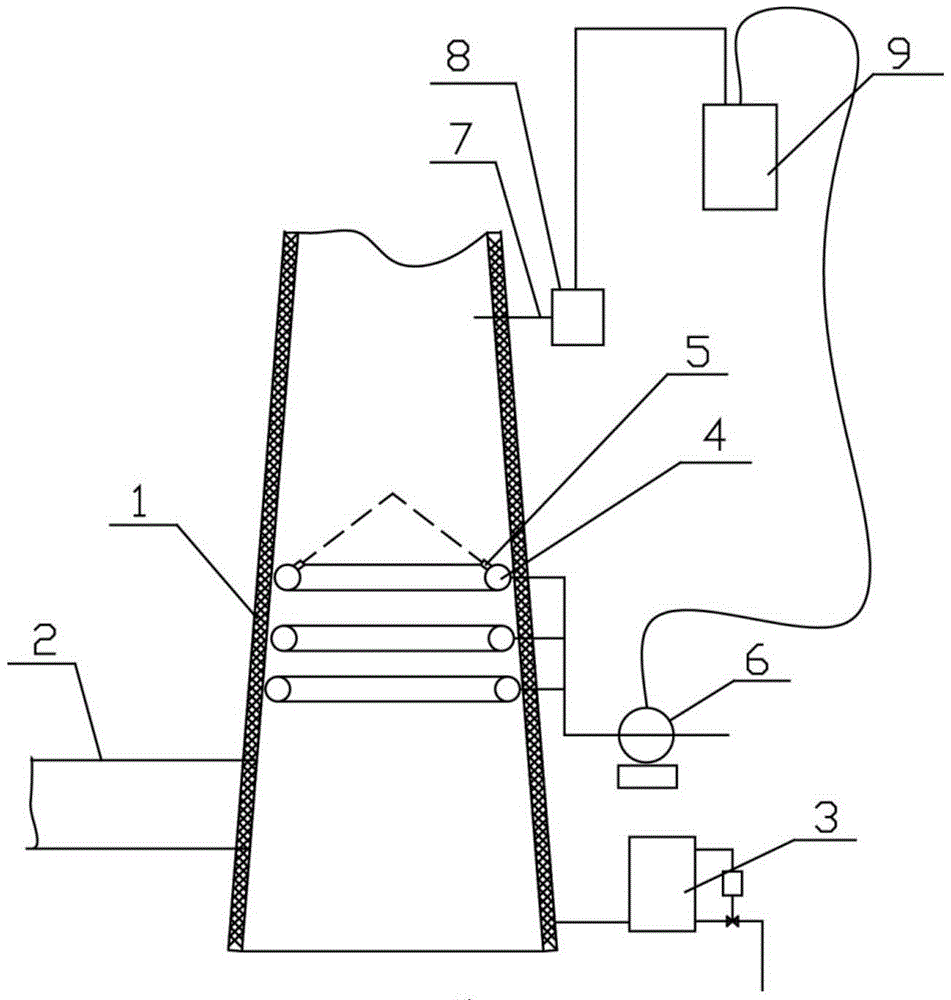

[0017] Such as figure 1 As shown, a boiler chimney dust removal system according to an embodiment of the present invention includes a drainage device 3, a spray device, a water pump 6, a sampler 7, a detector 8 and a controller 9, and the air inlet pipe 2 is installed at the bottom of the chimney 1 , the drainage device is installed at the bottom of the chimney 1 and below the intake pipe 2, the flue gas after a dust removal enters the chimney 1 from the intake pipe 2, and is discharged from the top of the chimney 1, and the spray device is installed on the chimney 1 Inside and above the intake pipe 2, it can ensure that the dust in the flue gas discharged from the intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com