A kind of ti2alnb intermetallic compound laser welding method

An intermetallic compound, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of lack of laser welding seam cold crack laser welding technology and other problems, and achieve good internal quality and appearance quality of welding seam , The comprehensive mechanical properties of the weld are excellent, and the weld is excessively smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

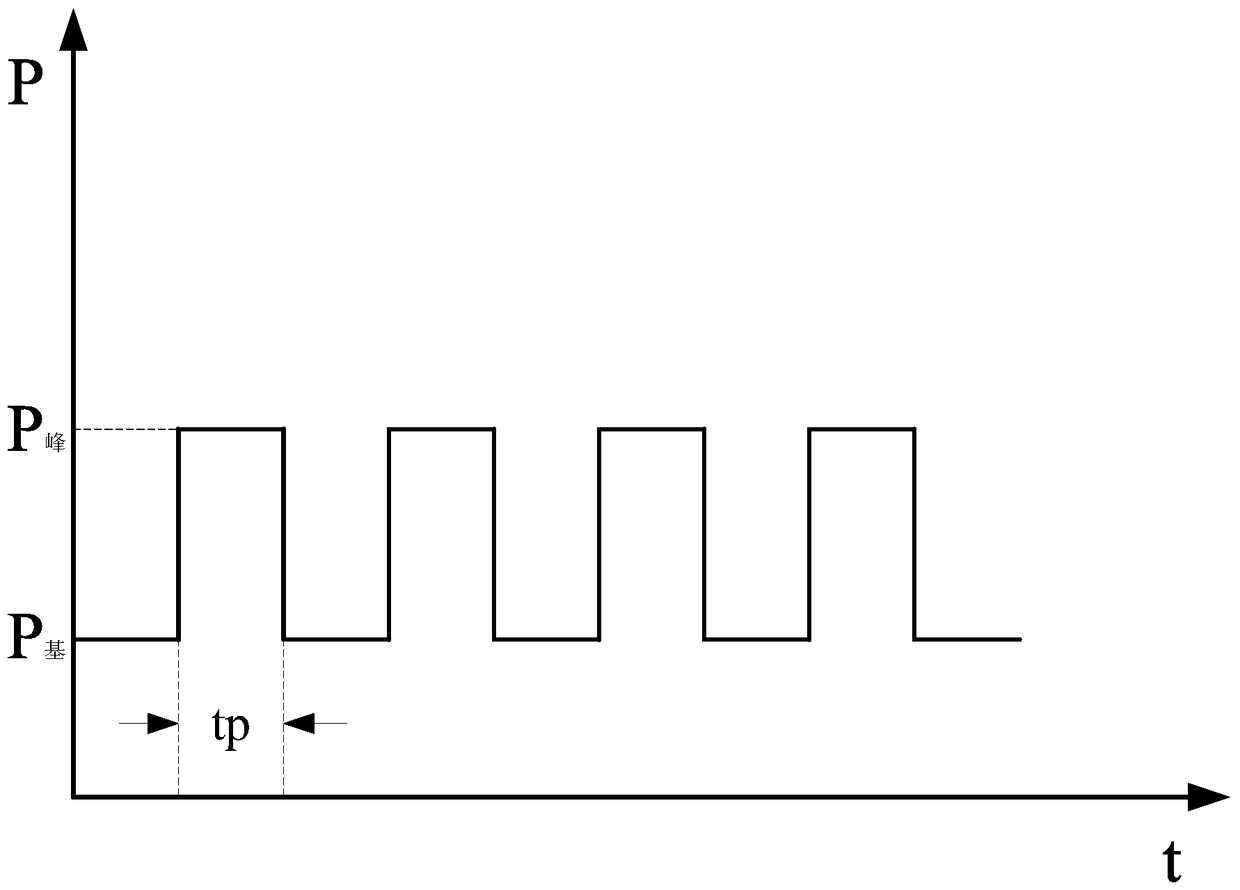

[0030] Example 1: Ti 2 AlNb intermetallic compound 1mm thick plate butt welding

[0031] Weld joint thickness 1mm Ti 2 AlNb intermetallic compound (cold rolled sheet) butt welding. Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the laser base power P 基 800W, laser peak power P 峰 1800W, pulse width tp is 20ms; welding speed v is 1300mm / min; spot diameter D is 0.45mm, defocus l is 0mm; 99.99% high-purity argon is used for front and back protection, and the front gas flow rate is 18L / min, the back gas flow rate is 5L / min; the welding arc closing distance is 1mm, and the continuous attenuation zigzag laser output is adopted. After the arc closing, the front side blowing gas and the back protection gas are delayed for 7s to 8s and then stop blowing. Welding result surface: The surface of the weld seam is well formed, without pores, cracks and other defects. The average tensile stre...

Embodiment 2

[0032] Example 2: Ti 2 AlNb intermetallic compound 2mm thick plate butt welding

[0033] Weld joint thickness 2mm Ti 2 AlNb intermetallic compound (hot rolled sheet) butt welding. Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the laser base power P 基 600W, laser peak power P 峰 1200W, pulse width tp is 20ms; welding speed v is 1200mm / min; spot diameter D is 0.45mm, defocus l is 0mm; 99.99% high-purity argon is used for front and back protection, and the front gas flow rate is 15L / min, the gas flow rate at the back is 4L / min; the welding arc closing distance is 2mm, and the continuous attenuation zigzag laser output is adopted. After the arc closing, the front side blowing gas and the back protection gas are delayed for 7s to 8s and then stop blowing. Welding result surface: The surface of the weld seam is well formed, without pores, cracks and other defects. The average tensil...

Embodiment 3

[0034] Example 3: Ti 2 AlNb Intermetallic Compound 3mm Thick Plate Butt Welding

[0035] Weld joint thickness 3mm Ti 2 AlNb intermetallic compound (hot rolled sheet) butt welding. Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the laser base power P 基 1000W, laser peak power P 峰2500W, pulse width tp is 20ms; welding speed v is 1500mm / min; spot diameter D is 0.45mm, defocus l is 0mm; 99.99% high-purity argon is used for front and back protection, and the front gas flow rate is 20L / min, the back gas flow rate is 6L / min; the welding arc closing distance is 3mm, and the continuous attenuation zigzag laser output is adopted. After the arc closing, the front side blowing gas and the back protection gas are delayed for 7s to 8s and then stop blowing. Welding result surface: The surface of the weld seam is well formed, without pores, cracks and other defects. The average tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com