Automatic centering slicer for areca nuts and slicing method thereof

A slicing machine and betel nut technology, applied in metal processing, etc., can solve the problems of two pieces of different sizes, oral injury of consumers, manual feeding, etc., and achieve the effect of small deviation of centering, saving personnel and work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

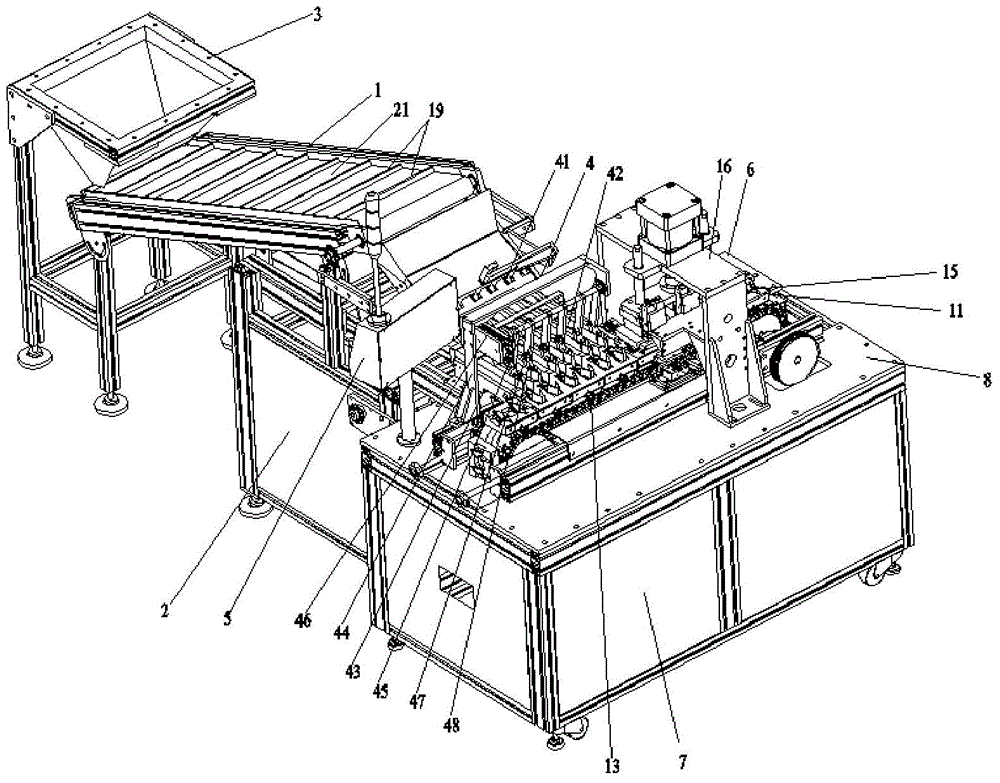

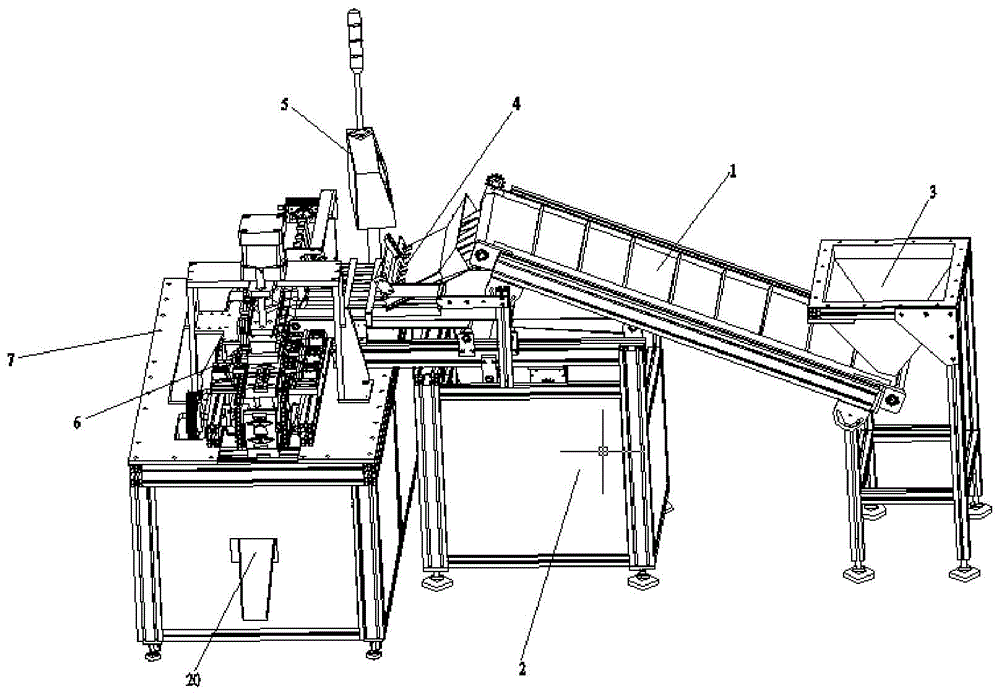

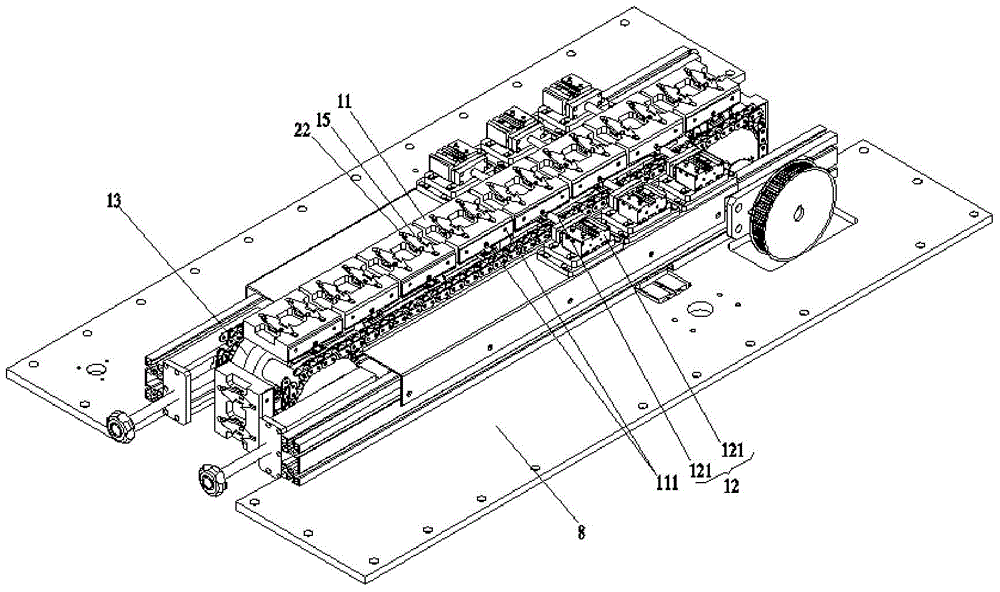

[0030] Such as figure 1 with Figure 4 As shown, a kind of betel nut automatic splitting slicer includes an automatic feeding mechanism 1, and the automatic feeding mechanism 1 is obliquely installed on the first frame 2, and a hopper 3 is provided above the automatic feeding structure 1; it also includes an automatic feeding mechanism 1. Feeding mechanism 4, control device 5 and cutting device 6, described automatic feeding mechanism 4 is installed in the downstream direction of described automatic feeding mechanism 1, and described cutting device 6 is installed on a side of described feeding mechanism 4, so The cutting device 6 is installed on the second frame 7, and the cutting device 6 includes a frame mounting plate 8 installed on the top surface of the second frame 7, an upper mold 9, an upper mold clamping device 10, a lower Die 11, lower mold positioning device 12, sprocket transmission device 13 and lower cutting device 14, said sprocket transmission device 13 is ins...

Embodiment 2

[0040] The slicing method of the betel nut described in embodiment 1 cuts the middle slicer automatically, comprises the following steps:

[0041] 1) Place the betel nut in the hopper on the automatic feeding device;

[0042] 2) Then transfer the betel nut to the automatic feeding mechanism;

[0043] 3) Finally, the betel nut on the automatic feeding mechanism is sent into the trough where the betel nut is positioned in the lower mold, the control device controls the servo motor to provide power, and the fixed-length rotation of the sprocket transmission device is realized through the servo, and the sprocket brings the betel nut to the cutting The position of the device, the positioning device of the lower mold positions the lower mold, and then the positioning groove of the upper mold and the material groove of the lower mold cover each other, the clamping device of the upper mold clamps the betel nut, the control device controls the cutter to perform positioning and cutting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com