Integral press-fitting and welding process for heavy-duty transmission shaft

A welding process and drive shaft technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of taking into account tolerances, long production tact, and out of tolerance, so as to shorten the length and reduce the number of personnel. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

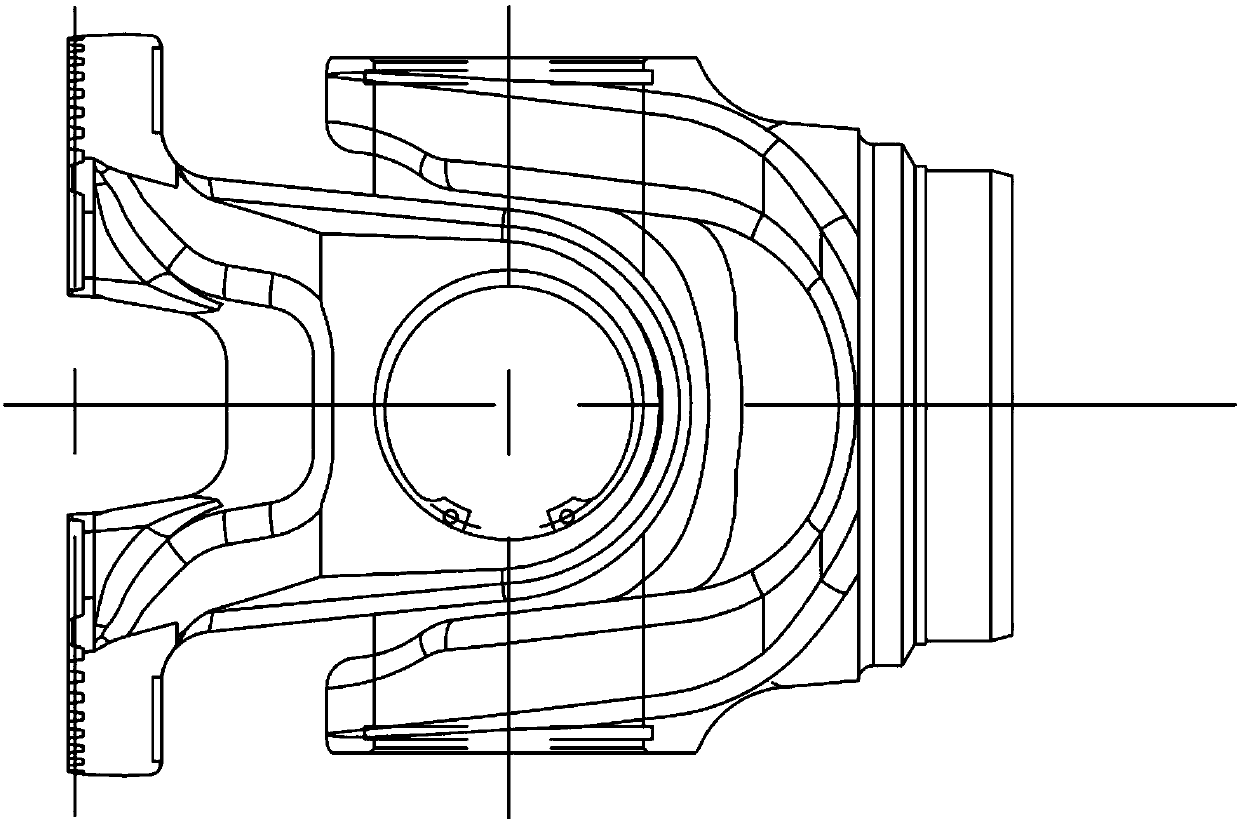

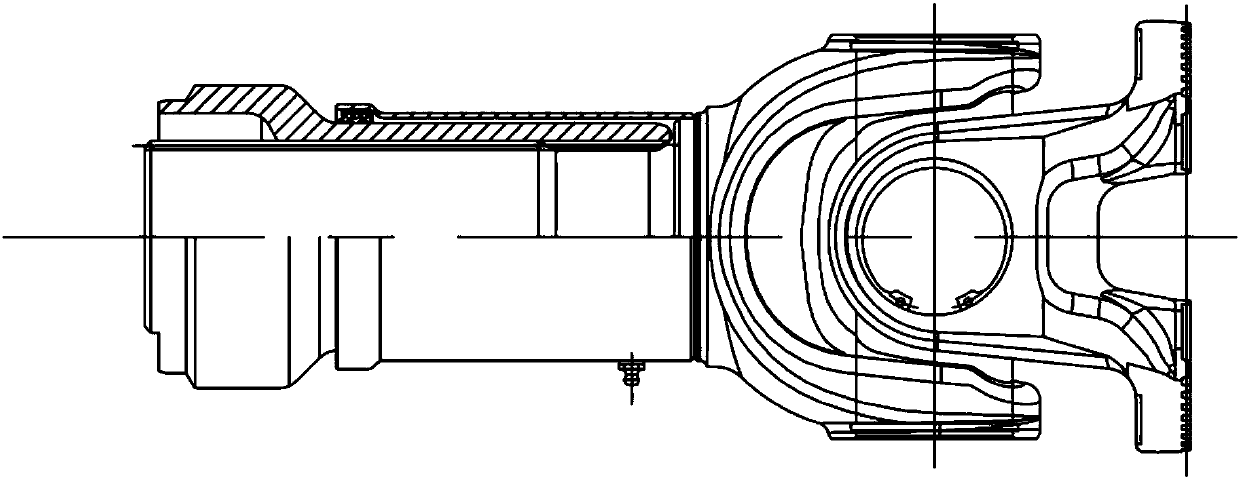

[0017] The present invention will be further described below in conjunction with accompanying drawing:

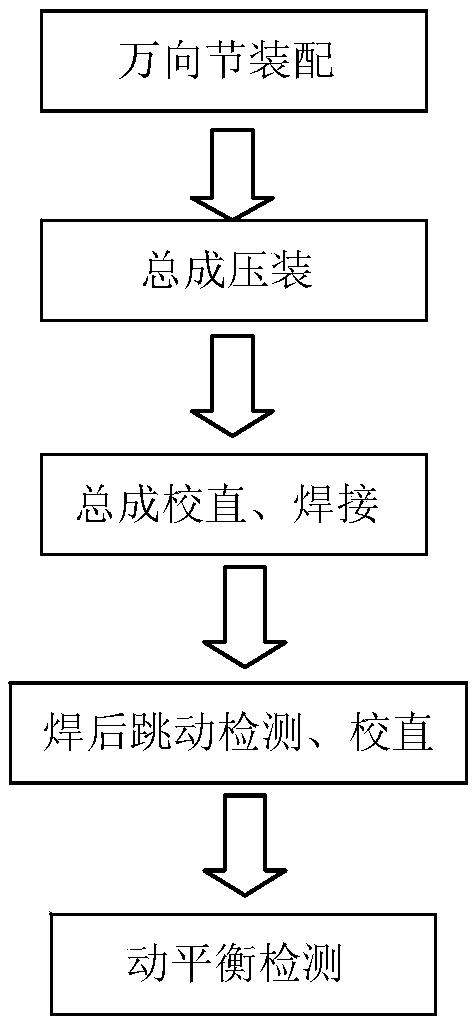

[0018] As shown in the figure, the overall press-fit welding process of the heavy-duty transmission shaft, the steps are as follows:

[0019] (1) Universal joint assembly;

[0020] (2) Assembly press-fitting: including welding fork small assembly and shaft fork small assembly;

[0021] (3) The assembly is relatively straight and welded;

[0022] (4) Runout detection after welding, straighter;

[0023] (5) Dynamic balance detection.

[0024] According to the production forecast order, the welding fork small assembly and the shaft fork small assembly are assembled online first. When the product is switched, only the clamps at both ends need to be replaced to achieve fast switching and improve production efficiency. The overall alignment welding is adopted to calculate all the shape and position tolerances of the parts into the runout of the drive shaft assembly, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com