A kind of preparation method of active khaki dye semi-finished product

A technology of semi-finished products and khaki, which is applied in the field of preparation of semi-finished products of reactive khaki dyes, which can solve the problems of large dust, poor color brightness, and difficult washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of above-mentioned active khaki dye semi-finished product, comprises the following steps:

[0022] (a) will Dissolve in water, adjust the pH to 6.7-7.2, then add acetic anhydride, heat up to 40-45°C, and react for 1-3 hours to obtain the first mixed solution. The molar ratio with the acetic anhydride is 1:1.05~1.1;

[0023] (b) will Dissolve in water, keep the temperature at 0-5°C, add equimolar amounts of hydrochloric acid and sodium nitrite solution to react for 1-3 hours, then add the first mixed solution to it, at 45-60°C, pH is 3.5 to 3.8 under the conditions of reaction for 1 to 3 hours to obtain the second mixed solution, the with the said The molar ratio is 1:1~105;

[0024] (c) Add diatomite to the second mixed solution, react at 40-50°C for 30-60 minutes, filter and dry the filtrate, and the volume ratio of the diatomite to the second mixed solution is 0.5~1%.

[0025] In step (a), control temperature 23~28 ℃ after adding ace...

Embodiment 1

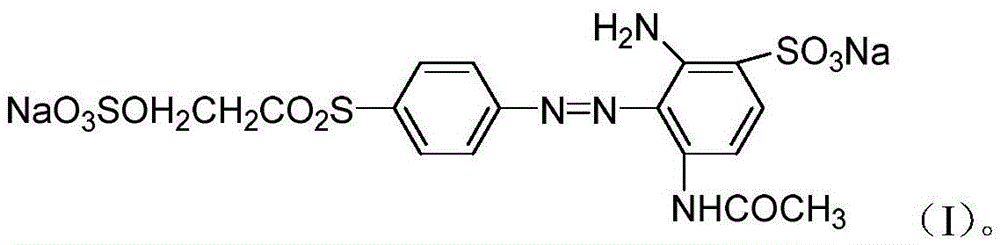

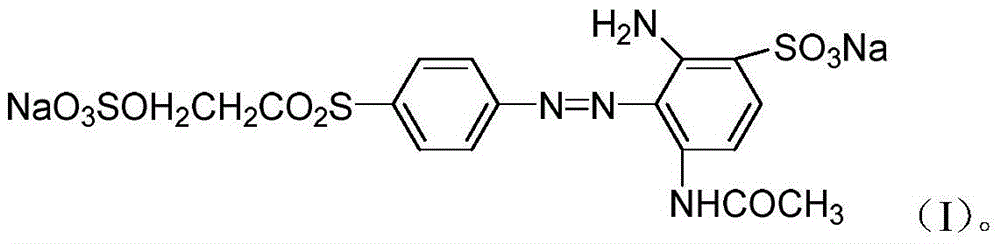

[0031] The present embodiment provides a kind of active khaki dye semi-finished product, and its chemical structural formula is:

[0032]

[0033] Its preparation method comprises the following steps:

[0034] (a) will Dissolve in water, adjust the pH to 6.7, then add acetic anhydride, control the temperature at 23°C, stir for 30 minutes, uniformly heat up to 40°C in 20 minutes, and react for 1 hour to obtain the first mixed solution. The mol ratio with described acetic anhydride is 1:1.05;

[0035] (b) will Dissolve in water, keep the temperature at 0°C, add equimolar hydrochloric acid and sodium nitrite solution dropwise at a rate of 0.5kg / hour for 3 hours, then add the first mixed solution to it, stir evenly and adjust the pH value to 2.5, continue to stir for 0.5 hours, control the temperature at 10°C, then adjust the pH value to 3.5 with 10wt% soda lye, raise the temperature to 45°C at a rate of 20°C / hour, and react for 1 hour to obtain the second mixed solution....

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of active khaki dye semi-finished product in embodiment 1, comprises the following steps:

[0039] (a) will Dissolve in water, adjust the pH to 7.2, then add acetic anhydride and control the temperature at 28°C, stir for 60 minutes, uniformly heat up to 45°C in 30 minutes, and react for 3 hours to obtain the first mixed solution. The mol ratio with described acetic anhydride is 1:1.1;

[0040] (b) will Dissolve in water, keep the temperature at 5°C, dropwise add equimolar hydrochloric acid and sodium nitrite solution to it at a rate of 2.5kg / hour to react for 3 hours, then add the first mixed solution to it, stir evenly and adjust When the pH value reaches 3.5, continue to stir for 1 hour, control the temperature to 15°C, then adjust the pH value to 3.8 with 30wt% soda lye, raise the temperature to 60°C at a rate of 30°C / hour, and react for 3 hours to obtain the second mixed solution. The molar ratio is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com