Method utilizing NaY molecular sieve to recycle rare earth from low concentration rare earth solution

A rare earth solution and molecular sieve technology, applied in the direction of improving process efficiency, can solve problems such as harming human health, affecting ecological safety, causing various diseases, etc., and achieve the effects of no environmental pollution, good regeneration, and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) SiO 2 :Al 2 o 3 : Na 2 O: H 2 Under the condition that the molar ratio is 7:1:12:420, stir vigorously to obtain a uniform sol. After half an hour, pour it into a stainless steel reactor lined with polytetrafluoroethylene, react at 100°C for 10 hours, and take out the reactor. Cool and take out the sample and dry it, it is NaY molecular sieve.

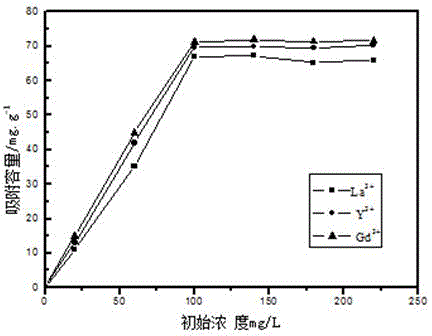

[0023] (2) Weigh 40 mg of NaY molecular sieve and add to the 3+ , Y 3+ , La 3+ In the rare earth wastewater (different initial concentrations of ions), when the adsorption time is 70min, pH=3, V=30ml, and 25°C, the filtrate is taken after suction filtration, and the residual rare earth ion content in the solution is determined by the arsenazoⅢ colorimetric method ( Measure absorbance, according to Gd 3+ , Y 3+ , La 3+ Calculate the amount of ions that are not adsorbed by the standard curve), and then obtain the amount of ions that are adsorbed by the subtraction method. Depend on figure 1 It can be seen that when ...

Embodiment 2

[0025] (1) SiO 2 :Al 2 o 3 : Na 2 O: H 2 Under the condition that the molar ratio is 7:1:12:420, stir vigorously to obtain a uniform sol. After half an hour, pour it into a stainless steel reactor lined with polytetrafluoroethylene, react at 100°C for 10 hours, and take out the reactor. Cool and take out the sample and dry it, it is NaY molecular sieve.

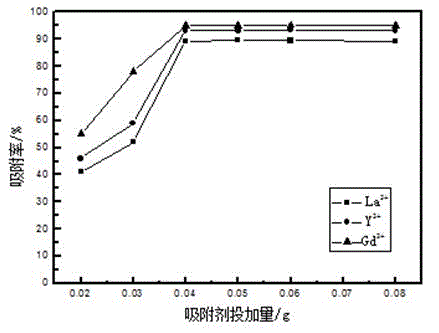

[0026] (2) In rare earth ions (Gd 3+ , Y 3+ , La 3+ ) when the initial mass concentration is 100mg / L, the adsorption time is 60min, pH=4, V=30mL, and 45°C, the effect of the amount of NaY molecular sieve adsorbent on the adsorption efficiency of rare earth ions is according to the arsenazo method in Example 1 Measure the concentration of the solution to obtain the amount of adsorbed ions, which is determined by figure 2 It can be seen that as the amount of adsorbent increases, the adsorption rate also increases; when the amount of adsorbent added is greater than 40mg, the increase in the adsorption efficiency is smal...

Embodiment 3

[0028] (1) SiO 2 :Al 2 o 3 : Na 2 O: H 2 Under the condition that the molar ratio is 7:1:12:420, stir vigorously to obtain a uniform sol. After half an hour, pour it into a stainless steel reactor lined with polytetrafluoroethylene, react at 100°C for 10 hours, and take out the reactor. Cool and take out the sample and dry it, it is NaY molecular sieve.

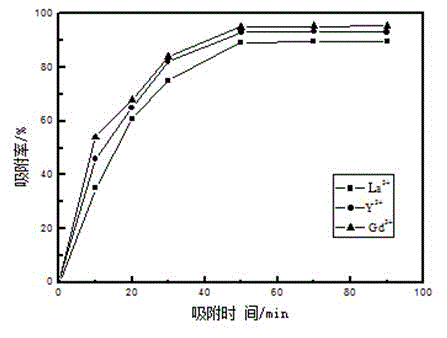

[0029] (2) In rare earth ions (Gd 3+ , Y 3+ , La 3+ ) When the initial mass concentration is 100mg / L, the amount of adsorbent added is 40mg, pH=3, V=30ml, and 35°C, the influence of adsorption time on the adsorption efficiency is determined by the arsenazo method in Example 1. Solution concentration, The amount of adsorbed ions is obtained by image 3 It can be seen that the adsorption rate increases gradually between 0 and 50 minutes. When the adsorption time is 50 minutes, 40 mg of the adsorbent has reached the saturated adsorption capacity, and the adsorption rate is the largest, reaching 95%. After 50 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com