Polyester fiber membrane for wastewater treatment and preparation method thereof

A polyester fiber membrane and wastewater treatment technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve good regenerative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

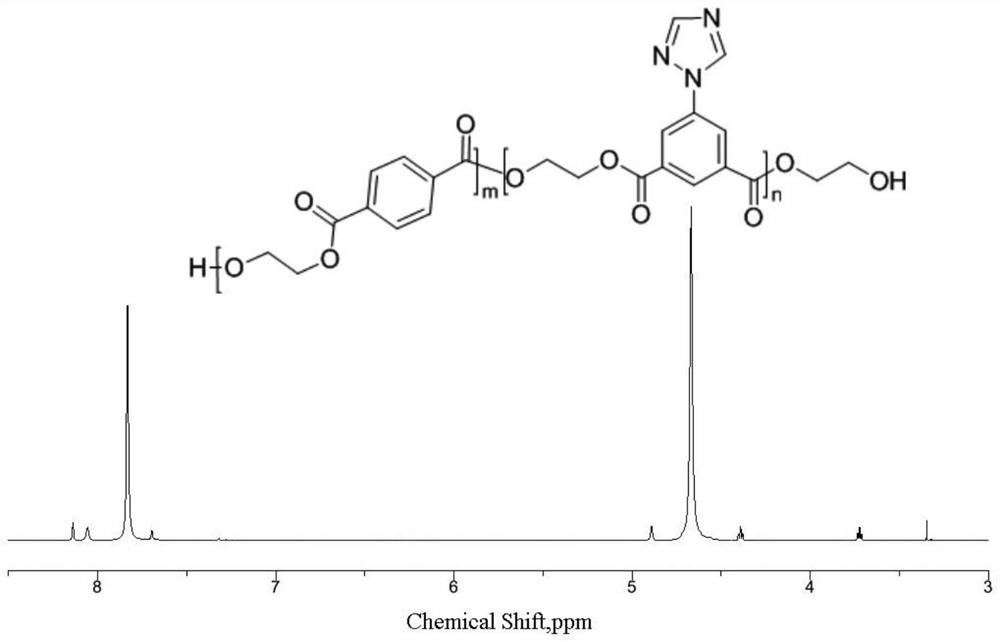

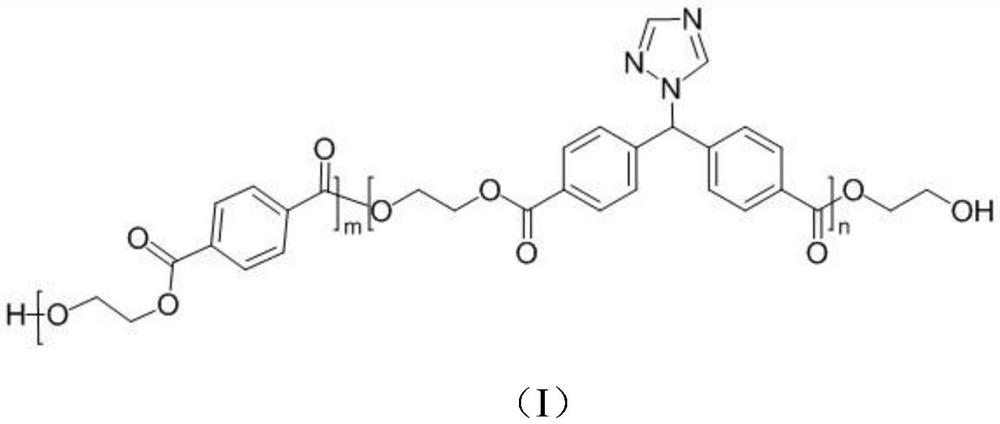

[0025] The first step: Weigh 5-(1H-1,2,4-triazol-1-yl) isophthalic acid, ethylene glycol, and antimony acetate into the reaction kettle, and feed N 2 , control the reaction pressure at 0.40MPa, carry out the esterification reaction at 200°C, stop the reaction when the esterification rate reaches 82%, and obtain 5-(1H-1,2,4-triazol-1-yl)isophthalic acid Ethylene formate.

[0026] Step 2: Weigh 5-(1H-1,2,4-triazol-1-yl)ethylene isophthalate, benzoic acid, ethylene glycol, antimony acetate and trimethyl phosphate into the reaction kettle , into N 2 , when the temperature rises to 240°C, start the vacuum pump, control the vacuum degree within 1000Pa, carry out the transesterification reaction for 1h, raise the temperature to 270°C, and the vacuum degree is lower than 50Pa, start the polycondensation reaction for 2h, release the vacuum with nitrogen and exit material to obtain copolyester.

[0027] The third step: use chloroform: trifluoroacetic acid volume ratio of 3:1 as the s...

Embodiment 2

[0033] The difference from Example 1 is:

[0034] In the second step, the feed ratio of benzoic acid, 5-(1H-1,2,4-triazol-1-yl) ethylene isophthalate, ethylene glycol is 150:20:180, antimony acetate and The quality of trimethyl phosphate is 0.05% (mass) of benzoic acid.

Embodiment 3

[0036] The difference from Example 1 is:

[0037] In the second step, the feeding ratio of benzoic acid, ethylene glycol 5-(1H-1,2,4-triazol-1-yl)isophthalate and ethylene glycol is 100:9:120.

[0038] In the third step, the electrospinning parameters are: spinning voltage 24kV, receiving distance 10cm, spinning solution flow rate 0.5mL / h, and spinning speed 40μm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com