Formula and production process for high strength-toughness traction bar bracket steel casting

A technology with high strength and toughness and production process, which is applied in the field of metal casting, can solve the problems that the thrust rod bracket is not strong enough, the mechanical properties cannot meet the needs of heavy trucks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

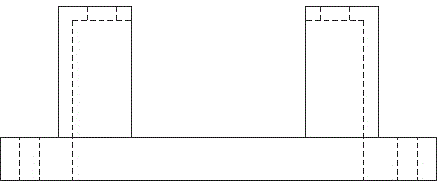

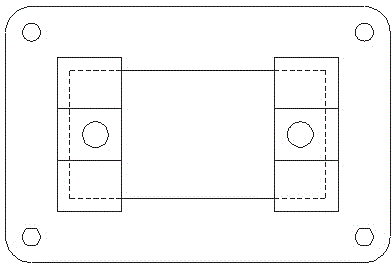

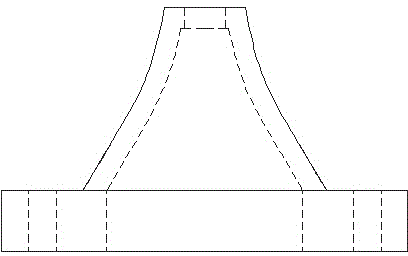

Image

Examples

Embodiment Construction

[0024] The preferred technical solution of the present invention will be described in detail below.

[0025] A high-strength and toughness thrust rod bracket casting steel casting formula according to the present invention, its chemical composition contains C: 0.3-0.45%, Si: <1.0%, Mn: ≤1.0%, P: 0.03%, S: 0.03%, Nb: 0.04 to 0.08%, and the balance is Fe. By appropriately reducing the carbon content of the material, the toughness of the core of the steel casting is improved, and a small amount of alloying element niobium is added to the material to refine the grain and strengthen the precipitation, and improve the mechanical properties of the material.

[0026] The present invention also provides a production process of high-strength and toughness thrust rod bracket steel castings, comprising the following steps:

[0027] 1) Molten steel smelting: smelt qualified molten steel in the medium frequency induction furnace according to the weight ratio of chemical composition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com