550 MPa-grade low-compression-ratio high-toughness steel plate for ocean engineering platform and production method

A low compression ratio, marine engineering technology, applied in the field of iron and steel materials, can solve the problems of difficult to guarantee the austenite deformation of the core structure, difficult to achieve large reduction in the rolling stage, high cost of heat treatment process, etc., to achieve the optimization of TMCP Process, optimization of tempering heat treatment temperature, optimization of cooling process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

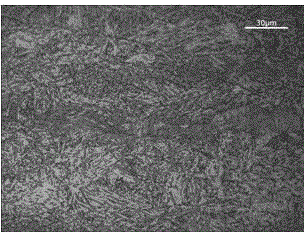

Image

Examples

Embodiment Construction

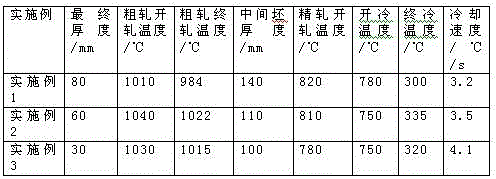

[0023] The technical solutions of the present invention will be described in detail below through specific examples.

[0024] The steel plate for marine engineering with low compression ratio and high toughness described in the present invention, in the smelting process, molten iron desulfurization ≤ 0.003%; billet P ≤ 0.010%, soft blowing for not less than 20 minutes after RH degassing, and calcium treatment after vacuum treatment , the target temperature of the continuous casting tundish is 1540°C, which is the liquidus temperature plus 15-25°C, and the casting speed is stable; the test results of the slab require that the center segregation C class ≤ 1.5, the center porosity ≤ 0.5, [N] ≤ 30ppm, [O ]≤25ppm, [H]≤1.5ppm, the molten steel is cast into 250mm thick slabs, and the off-line stacking is slowly cooled for 48 hours.

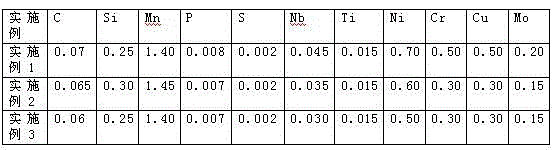

[0025] According to the production technique of the present invention, the actual chemical composition of the steel grade of the present invention for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com