Steel plate for ultra-low temperature and high pressure service delivery pipe and manufacturing method thereof

A manufacturing method and high-pressure technology, which is applied in the field of hot-rolled thick-walled steel plate and its manufacturing, can solve the problems that the mechanical properties cannot meet the design requirements, etc., so as to improve the low-temperature drop weight performance and welding performance, reduce grain growth, and high The effect of low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091]In Example 1 and Example 4, the CTOD test results of the steel plate at -40°C are shown in Table 8.

[0092] Table 8

[0093] Example δ 1 2 3 temperature, ℃ Example 1 δ m (mm)

2.265 1.933 2.105 -40 Example 4 δ m (mm)

2.119 2.207 1.825 -40

[0094] Figure 1a-Figure 1c Shown is the metallographic diagram of the 30 mm thick steel plate prepared in Example 4 (near surface × 500; thickness 1 / 4, × 500; thickness 1 / 2, × 500).

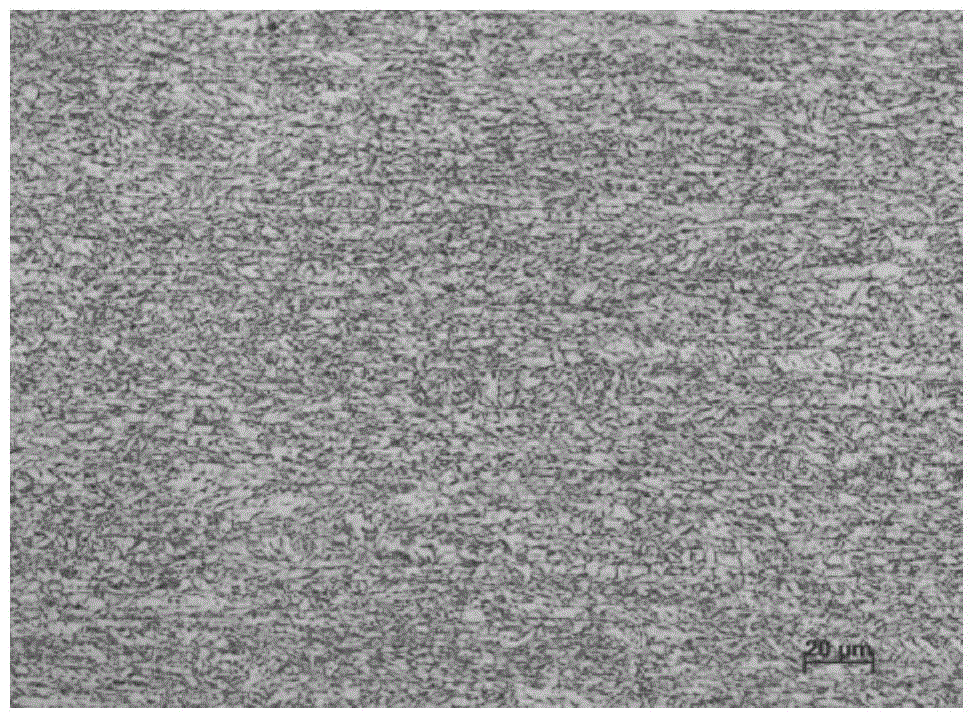

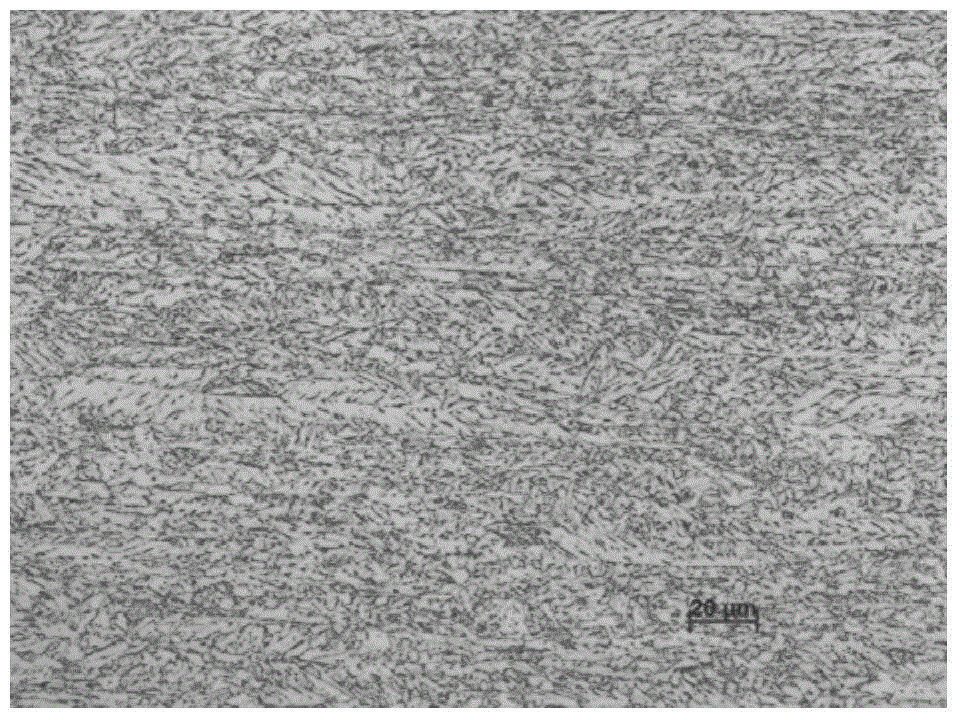

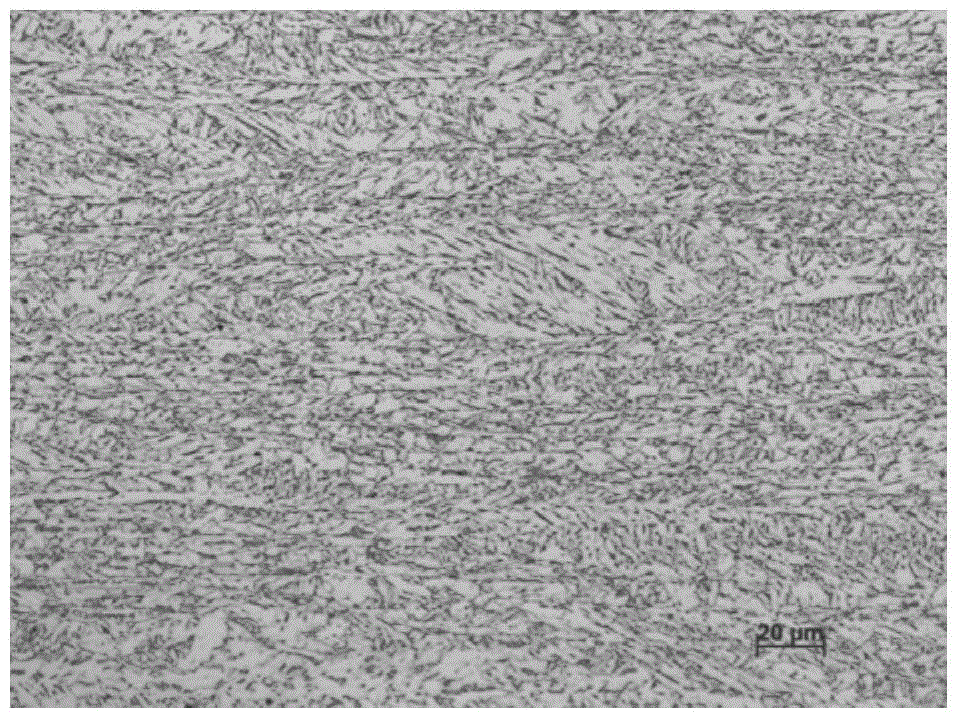

[0095] Figure 2a-Figure 2c Shown is the metallographic diagram of the 34 mm thick steel plate prepared in Example 1 (near surface × 500; thickness 1 / 4, × 500; thickness 1 / 2, × 500).

[0096] image 3 Shown is the ductile-brittle transition curve of the Charpy V-type impact test of the steel plate in Example 4.

[0097] Figure 4 Shown is the ductile-brittle transition curve of the Charpy V-type impact test of the steel plate in Example 1.

[0098] Figure 5 Shown is the PV curve of the CTOD load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com