Water taking and direct heat exchange system of sewage source heat pump

A sewage source heat pump and sewage technology, which is applied in the direction of heat pump, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems affecting the first-stage pump and the redundant setting of grit chambers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

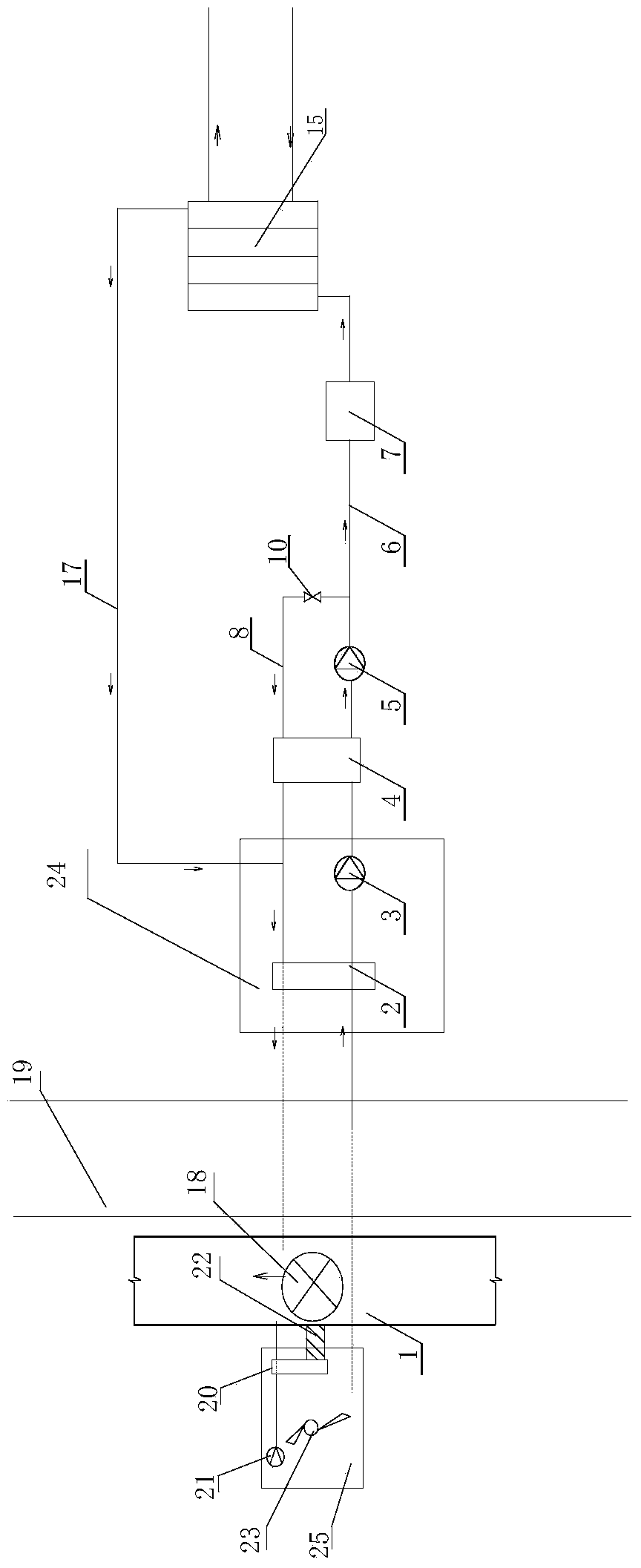

[0018] A sewage source heat pump water intake direct heat exchange system.

[0019] The technical solution adopted by the present invention to solve the technical problem is: including main sewage canal 1, water intake tank 24, automatic decontamination device 4, secondary pump 5, heat exchanger water inlet pipeline 6, hair filter 7, backwash pipeline 8. Sewage heat exchanger 15, heat exchanger return water pipeline 17, wherein the water intake pool 24 includes: secondary mechanical grille 2, primary pump 3;

[0020] Also includes municipal sewage well 18, road 19, drainage pipe 22, water diversion pool 25, primary mechanical grille 20, sewage pump 21, agitator 23;

[0021] The water diversion pool 25 and the water intake pool 24 are on both sides of the road 19 respectively. The municipal sewage well 18 of the main sewage canal 1 is connected to the water diversion pool 25 through the drainage pipe 22 and the first-level mechanical grille 20. The drainage pipe 22 takes water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com