Stamping die and vulnerable part informatization management system

A technology of information management and stamping dies, which is applied in the field of management systems, can solve problems such as the lack of timely maintenance or replacement of the wearing parts of stamping equipment, the high shutdown rate of stamping equipment, and the high mobility of technical personnel, etc., to achieve improvement Production efficiency, ensuring normal production, and reducing stamping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

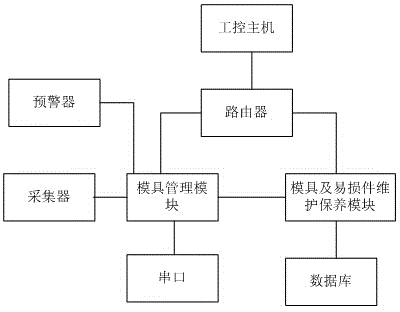

[0010] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0011] Such as figure 1 As shown, the information management system for stamping dies and wearing parts of the present invention includes an industrial control host, a router, a database, a mold management module, and a maintenance module for molds and wearing parts, and an industrial control host, a mold management module, and a maintenance module for molds and wearing parts. The modules are all connected to the router, and the maintenance module for molds and wearing parts is also connected to the database. The mold management module is connected with a serial port, which is convenient for driving. The mold management module is connected with a collector, so that it is convenient to collect the data of each pair of molds. The mold management module and the mold and wearing parts main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com