Finite element grid automatic generation method of profiling cylindrical gear

A cylindrical gear, automatic generation technology, applied in image data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

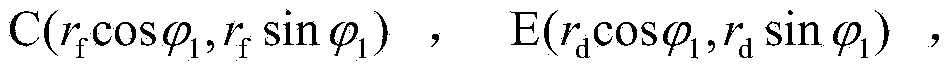

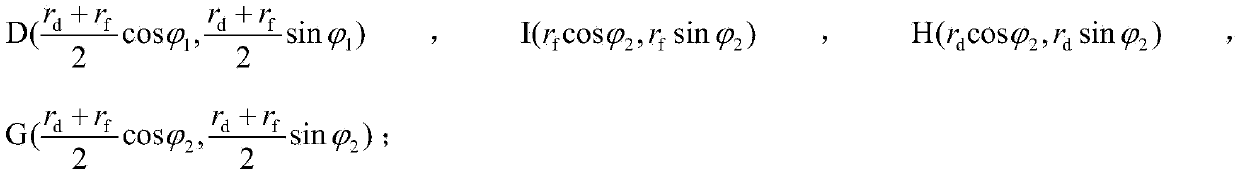

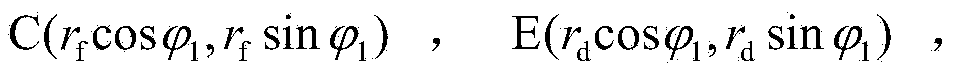

[0054] The present invention is a rapid modeling method designed for finite element modeling of cylindrical gears. Taking a gear with a modulus of 5 as an example, the modeling flow chart is shown in the figure. This implementation example takes the small wheel in the table parameters as the object, and the implementation steps of the modeling are as follows:

[0055] Step (1): given the basic parameters

[0056]

[0057] Step (2): Calculate the pitch circle, addendum circle, and dedendum radius of the gear according to the basic parameters and installation parameters, combined with the tooth height coefficient and head clearance coefficient.

[0058] h a * = 1

[0059] c * =0.25

[0060] r p = m t · ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com