Pixel unit and preparation method thereof, oled array substrate and display device

A pixel unit, pixel technology, applied in electrical components, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc., can solve the problems of low life and efficiency, narrow color range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

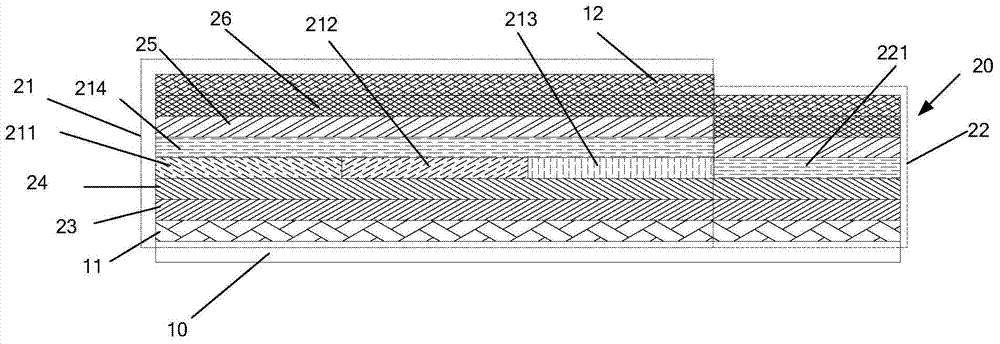

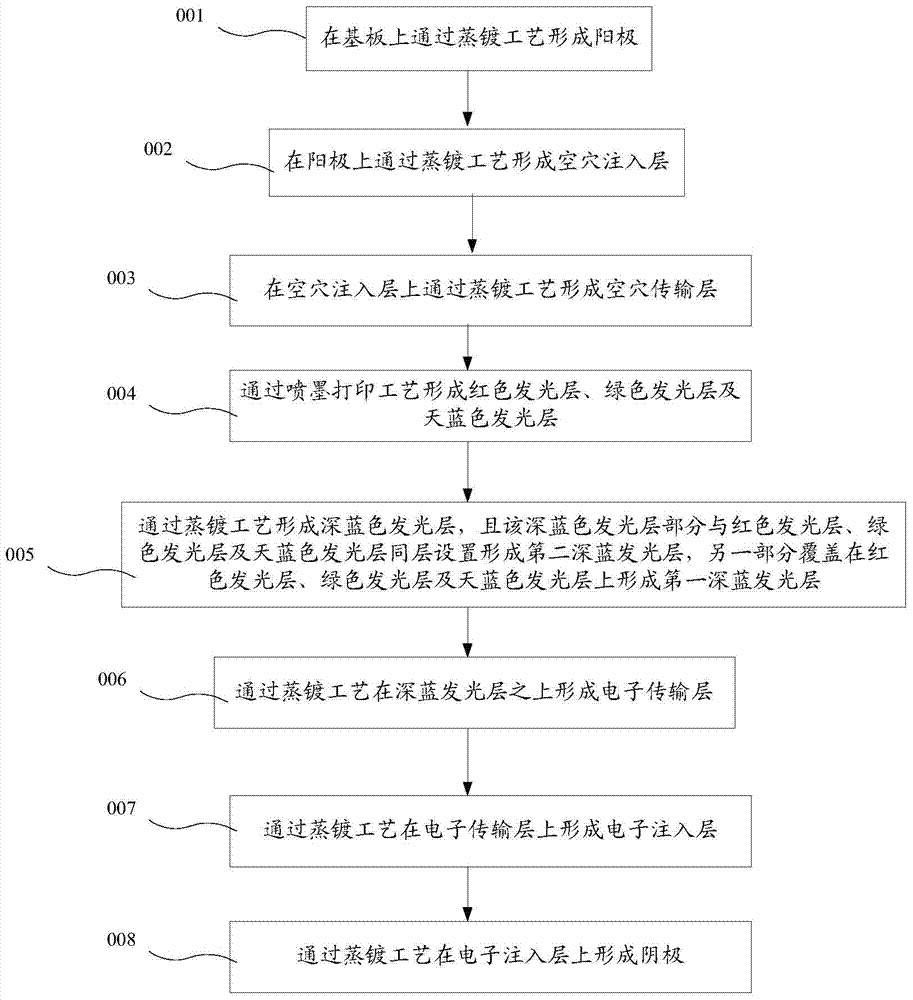

[0047] In addition, an embodiment of the present invention also provides a method for preparing a pixel unit, which is the method for preparing a pixel unit mentioned in the above embodiments, such as figure 1 As shown, the pixel unit includes: red, green and blue sub-pixels 21 and dark blue sub-pixels 22; wherein,

[0048] The red, green and blue sub-pixels 21 include: an anode and a cathode arranged opposite to each other, and a light-emitting layer located between the anode and the cathode. Layer 213, covering the red light emitting layer 211, the green light emitting layer 212 and the first dark blue light emitting layer 214 of the sky blue light emitting layer 213;

[0049] The dark blue sub-pixel 22 includes an anode and a cathode disposed opposite to each other, and a second dark blue light emitting layer 221 disposed between the anode and the cathode.

[0050] The method includes the following steps:

[0051] Forming a red light emitting layer 211, a green light emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com