Light source comprising a saturated colour appearance

A light source, light color technology, applied in the field of fluorescent lamps, can solve the problems of discomfort, low heat resistance of filter film, inability to color saturation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

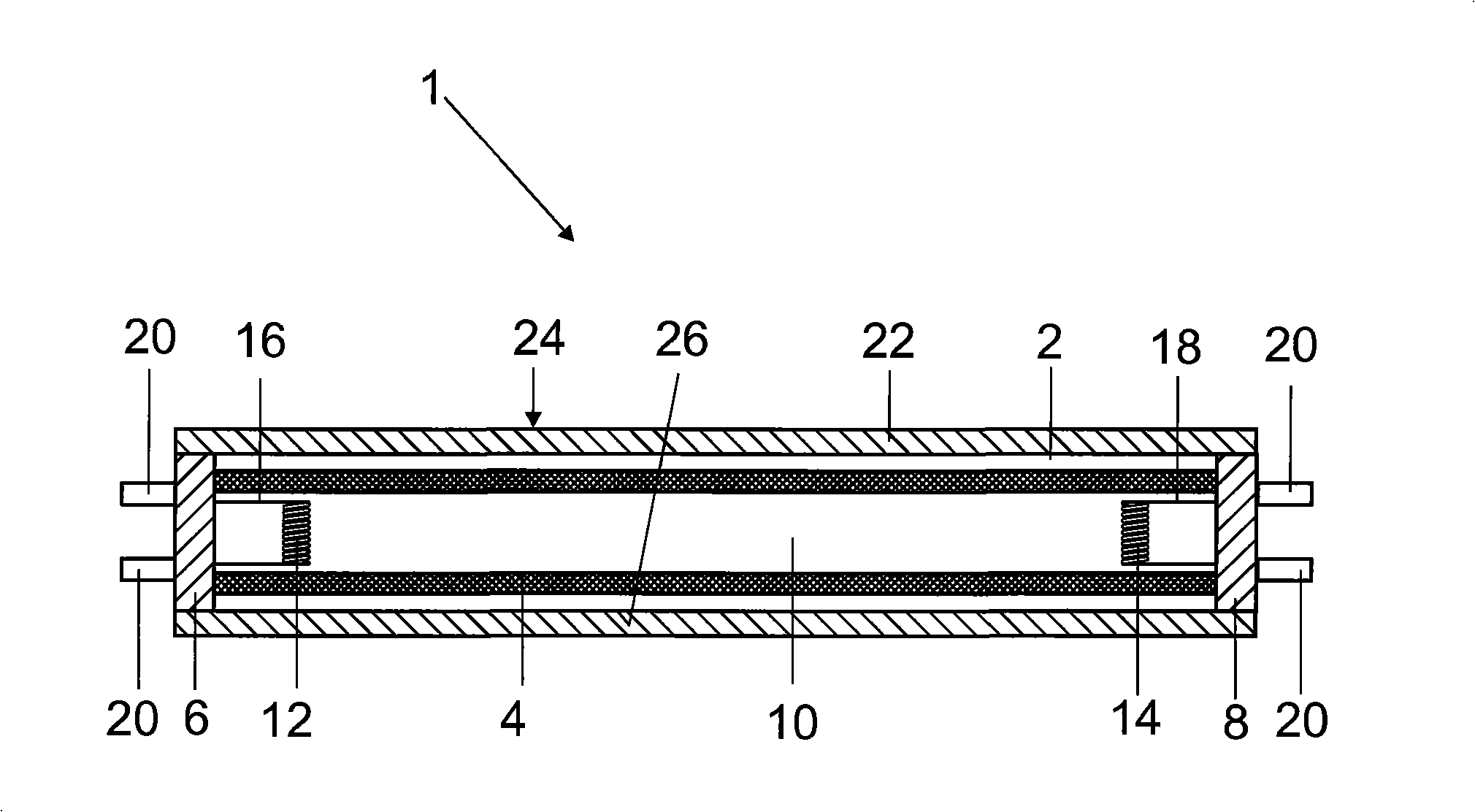

[0015] figure 1 A schematic diagram of a light source according to the invention embodied as a fluorescent lamp 1 is shown. The light source has, for example, a rod-shaped or tubular lamp vessel 2 made of glass, which is provided with a phosphor layer 4 . The lamp vessel 2 has an inner space 10 sealed on both sides by cap parts 6 , 8 , into which two diametrically opposed electrodes 12 , 14 (incandescent filaments) protrude, between which a gas forms during lamp operation. discharge. The electrodes 12, 14 are connected for electrical contact via feeders 16, 18 respectively to contact rods 20, which pass through the base parts 6, 8 and are connected to corresponding sockets (not shown) of the illuminants to enable Stable mechanical holding and reliable electrical contacting of the fluorescent lamp 1 . An ionizable filling, which essentially consists of one or more noble gases and a small amount of mercury, is contained in the interior 10 of the lamp vessel 2 . High temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com