Capacity grading method for specially-shaped lithium ion batteries

A lithium-ion battery, ion battery technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery charging/discharging, etc. problems, to achieve the effect of improving market competitiveness, simplifying the capacity distribution process, and shortening the capacity distribution time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

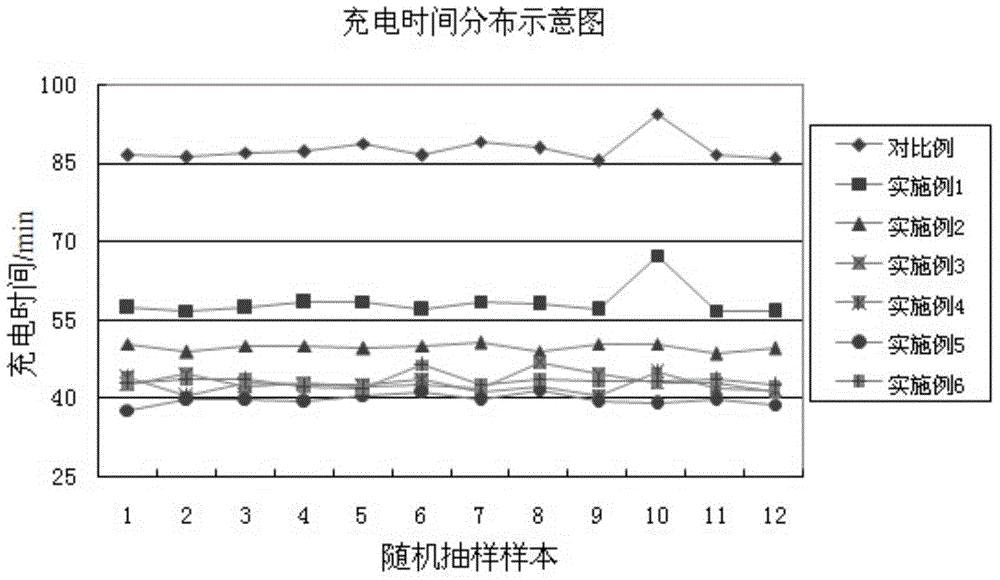

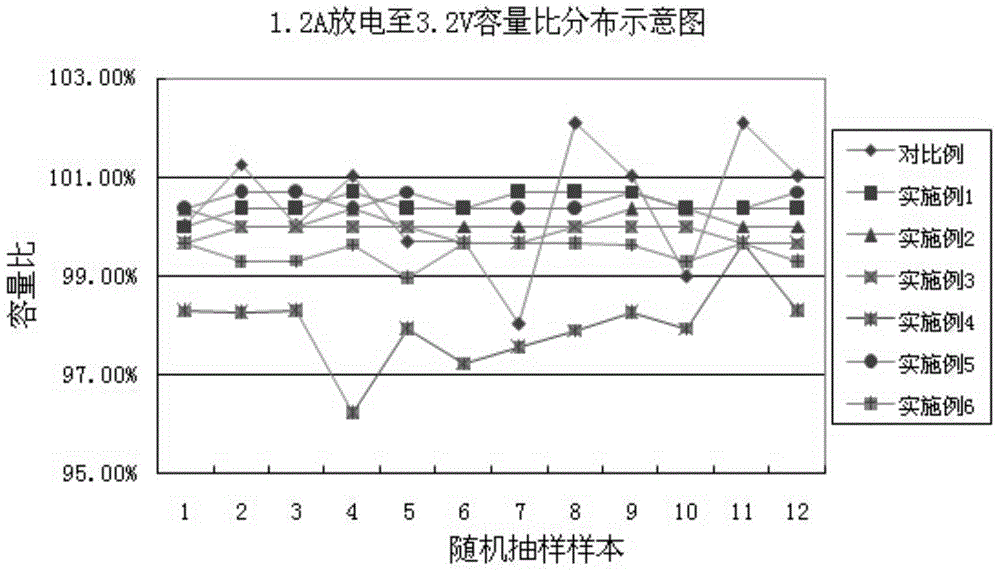

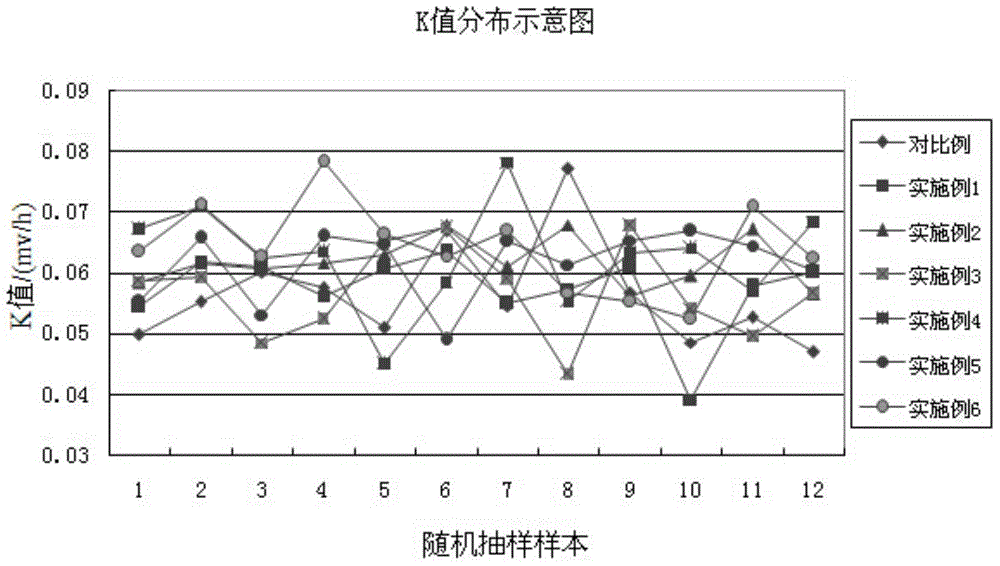

[0020] For the heat-sealed special-shaped lithium-ion battery, the capacity is divided at room temperature. When dividing the capacity, it is not necessary to discharge first, but to charge directly. The specific capacity division steps are as follows:

[0021] First, carry out the first charging stage, charge at 2.0C constant current and constant voltage, cut-off current 0.02C to 4.2V, and put it aside for 5 minutes;

[0022] Then carry out the second discharge stage, discharge to 3.2V at 1200mA, and leave for 5min;

[0023] Carry out the second charging stage again, charge to 4.2V with 2.0C constant current and constant voltage, cut-off current 7mA, and put it aside for 5min;

[0024] Carry out the third charging stage again, charge to 4.2V with 0.02C constant current and constant voltage, cut-off current 7mA, and complete the capacity division.

[0025] Among them, 12 special-shaped lithium-ion batteries were randomly selected to record their charging time, and at the same...

Embodiment 2

[0027] For the heat-sealed special-shaped lithium-ion battery, the capacity is divided at room temperature. When the capacity is divided, it is not necessary to discharge first, but directly to the charging stage. The specific capacity division steps are:

[0028] First, carry out the first charging stage, charge at 3.0C constant current and constant voltage, cut-off current 0.02C to 4.2V, and put it aside for 5 minutes;

[0029] Then carry out the second discharge stage, discharge to 3.2V at 1200mA, and leave for 5min;

[0030] Carry out the second charging stage again, charge to 4.2V with 3.0C constant current and constant voltage, cut-off current 7mA, and put it aside for 5min;

[0031] Carry out the third charging stage again, charge to 4.2V with 0.02C constant current and constant voltage, cut-off current 7mA, and complete the capacity division.

[0032] Among them, 12 special-shaped lithium-ion batteries were randomly selected to record their charging time, and at the s...

Embodiment 3

[0034] For the heat-sealed special-shaped lithium-ion battery, the capacity is divided at room temperature. When the capacity is divided, it is not necessary to discharge first, but directly to the charging stage. The specific capacity division steps are:

[0035] First, carry out the first charging stage, charge at 4.0C constant current and constant voltage, cut-off current 0.02C to 4.2V, and put it aside for 5 minutes;

[0036] Then carry out the second discharge stage, discharge to 3.2V at 1200mA, and leave for 5min;

[0037] Carry out the second charging stage again, charge to 4.2V with 4.0C constant current and constant voltage, cut-off current 7mA, and put it aside for 5min;

[0038] Carry out the third charging stage again, charge to 4.2V with 0.02C constant current and constant voltage, cut-off current 7mA, and complete the capacity division.

[0039] Among them, 12 special-shaped lithium-ion batteries were randomly selected to record their charging time, and at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com