Single secondary battery formation method

A technology of secondary battery and formation method, which is applied in the direction of secondary battery, secondary battery charging/discharging, secondary battery repair/maintenance, etc. Reduced equipment types and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

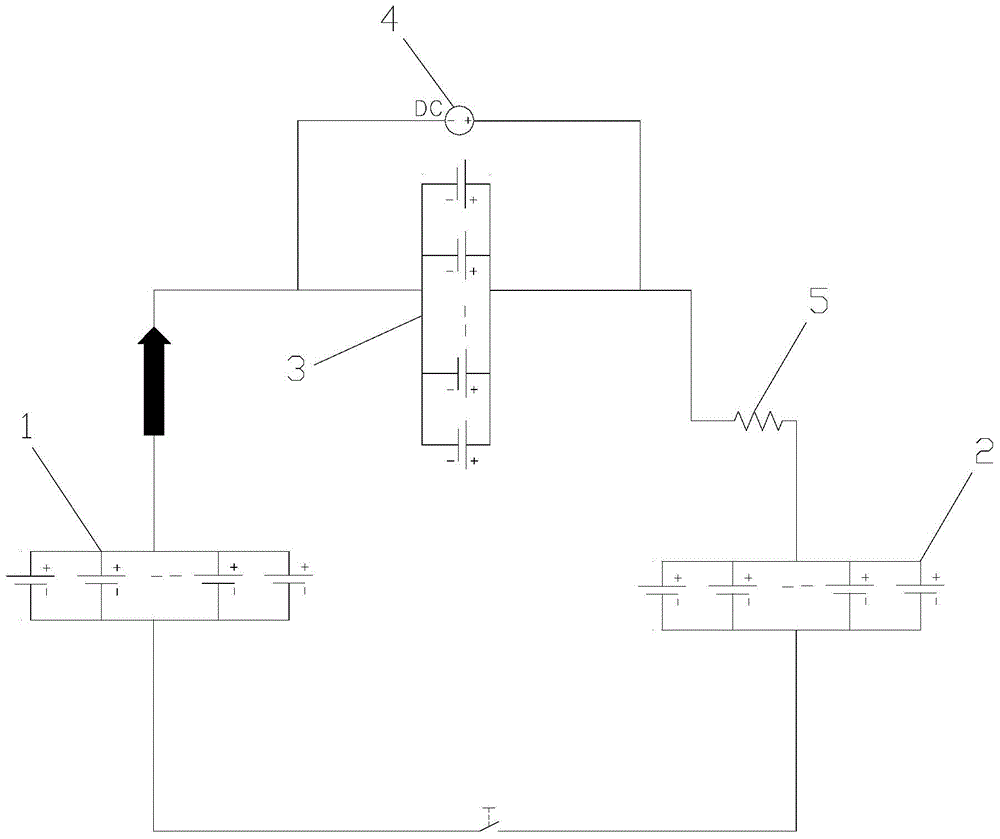

[0029] refer to figure 1 , the formation method of a single secondary battery, first connect a plurality of single secondary batteries that need to be discharged and formed in parallel to form a discharge battery module 1, and connect a plurality of single secondary batteries that need to be charged and formed in parallel to form a The rechargeable battery module 2, there is a voltage difference between the discharge battery module 1 and the rechargeable battery module 2, after the discharge battery module 1 is connected in series with a boost energy storage battery module 3, it is connected in parallel with the rechargeable battery module 4 to form a charge-discharge circuit, the boosted energy storage battery module 3 is connected with a charging circuit 4 that keeps the voltage of the boosted energy storage battery module 3 stable, and when the single secondary battery in the discharged battery module 1 is discharged, the voltage is maintained at a stable voltage. The boost...

Embodiment 2

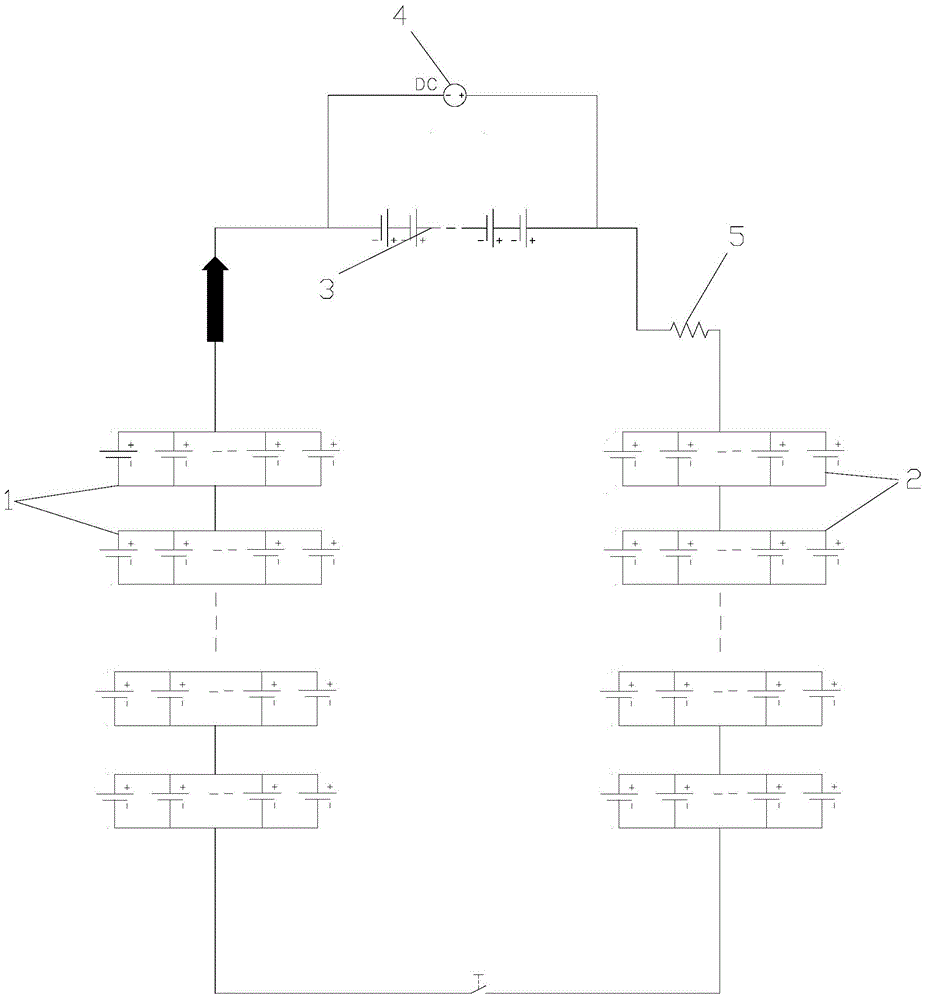

[0037] refer to figure 2 The difference between this embodiment and the first embodiment is that the discharge battery module 1 is composed of a plurality of discharge battery modules 1 connected in series. The rechargeable battery module 2 is also composed of multiple rechargeable battery modules 2 connected in series. It can realize the formation of larger batches of single secondary batteries and improve efficiency. The rest of the structures and functions are the same as those in Embodiment 1.

Embodiment 3

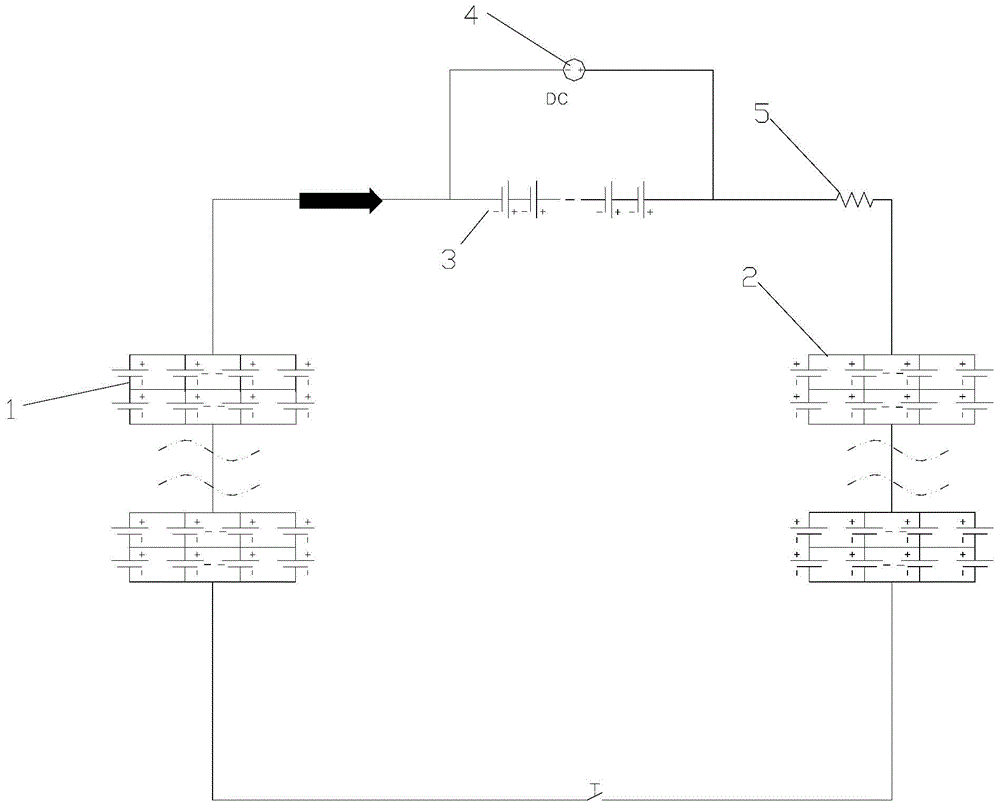

[0039] refer to image 3 , Figure 4 The difference between this embodiment and the first embodiment is that the discharge battery module 1 is a single secondary battery lattice structure composed of a plurality of single secondary batteries mixed and connected in series. The rechargeable battery module 2 is a lattice structure of single secondary batteries composed of a plurality of single secondary batteries mixed and connected in series. It can realize the formation of more batches of single secondary batteries and improve efficiency. The rest of the structures and functions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com