Pneumatic vehicle tyre

A technology for pneumatic tires and tires, applied to vehicle parts, tire parts, tire sidewalls, etc., can solve the problem of exhaust gas, reduce the service life of shadow patterns, side shell pollution, etc., and achieve the effect of improving frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

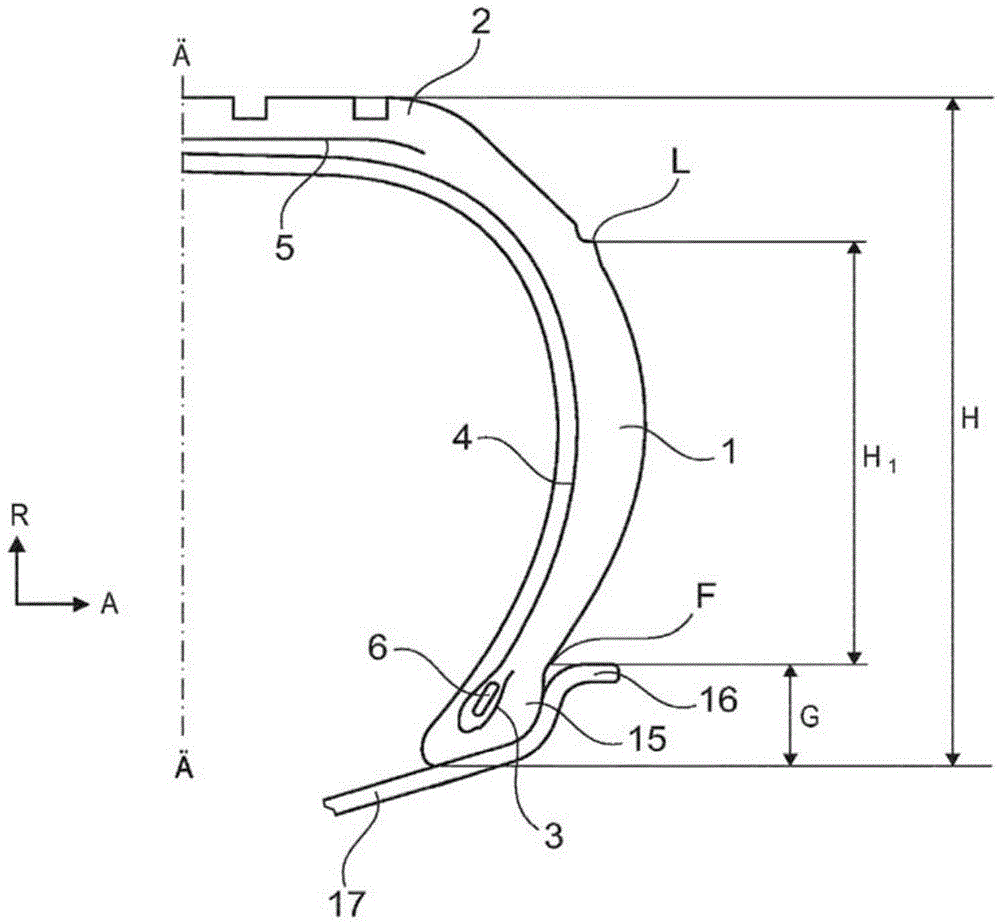

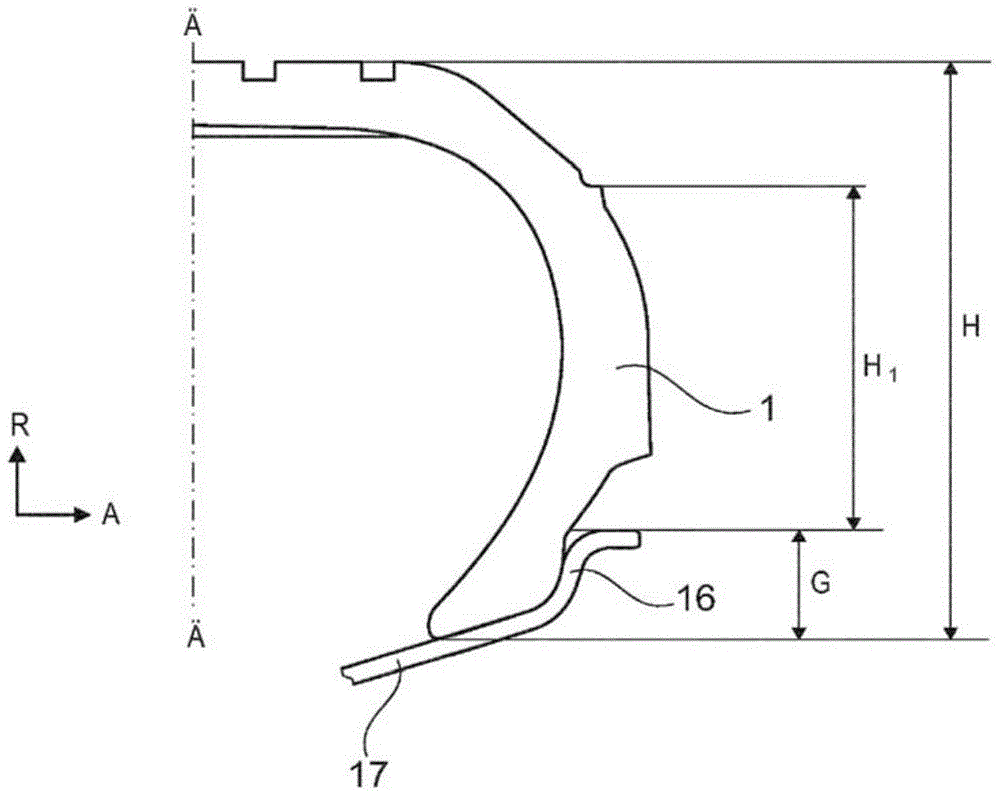

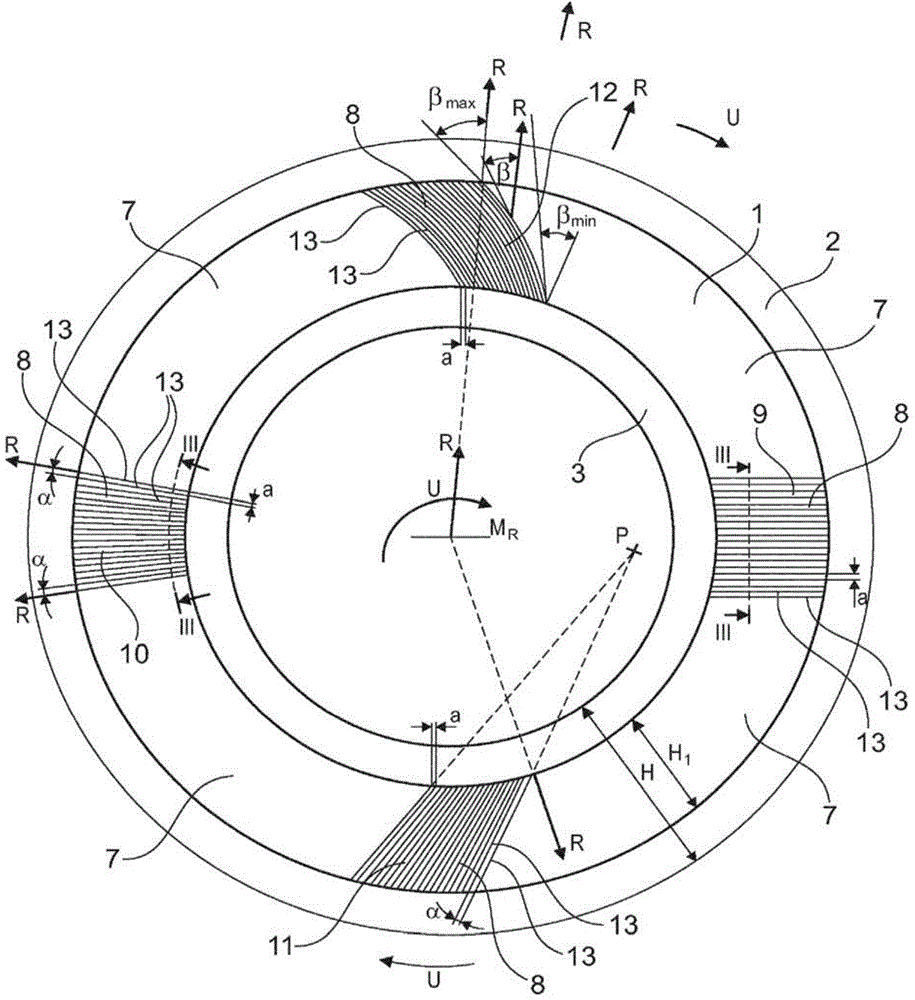

[0027] figure 1By way of example, a construction of a pneumatic vehicle tire for passenger cars mounted on a rim 17 is shown, in which a bead core 6 (not shown) with a core profile is surrounded by a bead core 6 consisting of one or more layers. The carcass 4 of radial construction is surrounded in a conventionally known manner by carcass layers arranged one above the other starting from the bead core 6 between an inner layer of a known type formed particularly airtight extends inwardly through the shoulder area shown on the right (equatorial plane of the vehicle's pneumatic tire ), the shoulder area on the left (not shown) and up to the bead core with the core profile on the left (not shown), so that it is surrounded in a conventional manner.

[0028] For simplicity, in figure 1 Only the construction half on its right side is shown in Pneumatic tires for vehicles in , the construction halves go all the way to the equatorial plane These carcass plies consist in a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com