Workpiece deformation correction method based on support vector machine

A technology of support vector machine and workpiece, applied in the field of workpiece correction, can solve problems such as complex deformation mechanism of workpiece, save test cost and time, improve efficiency and accuracy, and realize the effect of remote operation monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

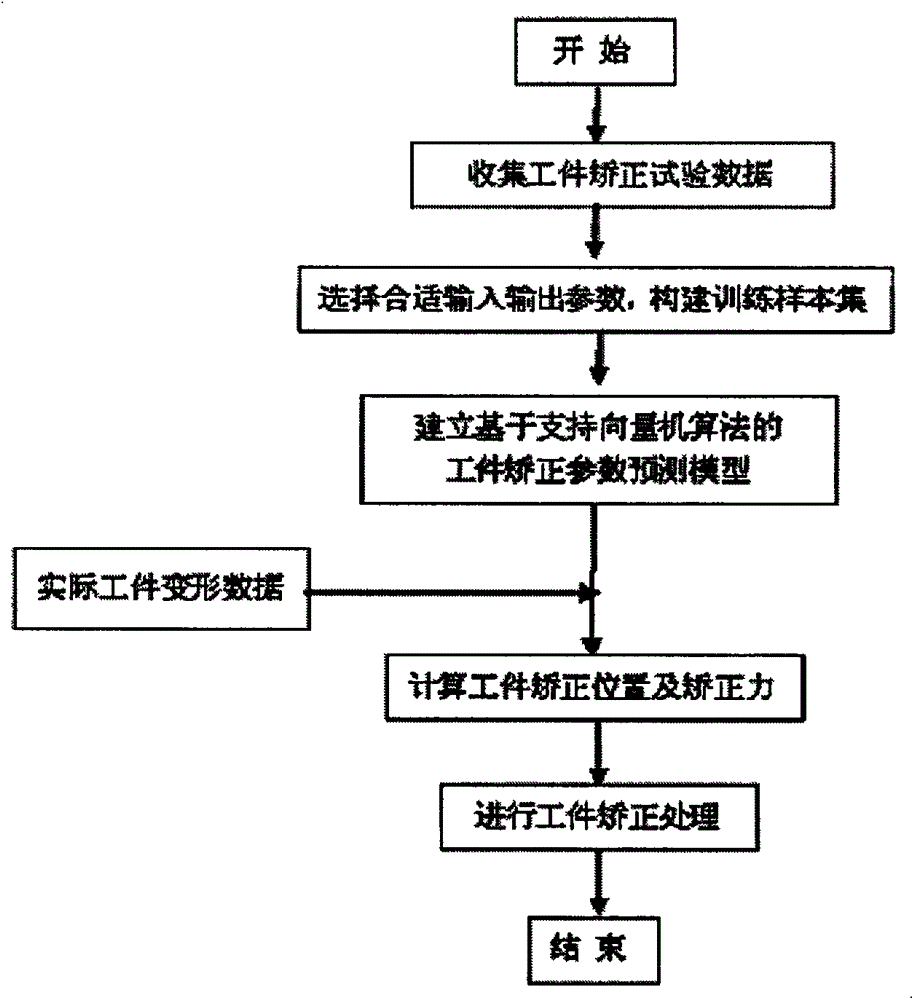

[0012] Collect workpiece deformation correction data: conduct correction tests on workpieces in different materials, different sizes, different deformation positions, and different deformation degrees, and collect data on the position and size of the correcting force. If conditions are not met, past experience data can be collected.

[0013] Process the test data and create training samples. The input parameters include material parameters, workpiece size, deformation position, and deformation amount, and the output parameters are correction position and correction force. The parameters are normalized.

[0014] The training samples are input into the support vector machine algorithm, the kernel function adopts the radial basis function, and the relevant parameters are automatically optimized through the cross-validation method. Through calculation, a prediction model of workpiece correction parameters based on support vector machine algorithm is established.

[0015] The ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com