Milling machine waste collector

A waste collection and milling machine technology, which is applied to milling machine equipment, milling machine equipment details, maintenance and safety accessories, etc., can solve the problems of low efficiency and poor collection effect of iron filings, so as to prevent iron filings from hurting people's feet and ensure Cleanliness and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

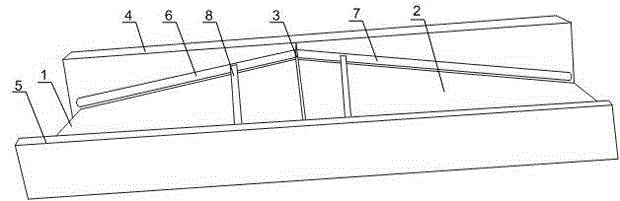

[0023] Such as figure 1 As shown, this embodiment includes a plurality of sequentially connected collecting units, and the collecting units are arranged at the bottom of the external milling machine, and also include a conveying mechanism arranged under the collecting units. A large number of iron chips produced by the milling machine processing of large workpieces. The multiple collection units connected in sequence at the bottom of the milling machine can collect waste from one or more milling machines, which greatly improves the efficiency of the overall processing process of the milling machine; The transmission mechanism under the unit can transfer a small amount of iron filings and engine oil splashed on the ground to the recovery pool for recycling, ensuring a clean operating environment and preventing iron filings from hurting people's feet or preventing workers from slipping and falling. Described collecting unit comprises the left base plate 1 of inclined setting, th...

Embodiment 2

[0026] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the transmission mechanism includes a groove, a spiral and a fence, the spiral is placed at the bottom of the groove, and the fence is arranged on the groove. When the iron filings and engine oil on the left bottom plate 1 or right bottom plate 2 flow into the groove, the screw installed in the groove is driven, and the iron filings or engine oil start to move in a fixed direction under the drive of the screw blade until Arriving in the recovery pool specially for iron filings, it solves the problem that the remaining iron filings are difficult to clean up; when the screw is driven, there is also a fence above the groove, which can ensure the safety of personnel and avoid safety problems caused by falling into the groove.

Embodiment 3

[0028] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the angle formed between the left bottom plate 1 and the right bottom plate 2 is 120° to 150°. Within the angle range of 120-150°, the operator can quickly collect iron filings and engine oil by using the inclined plane. When it is higher than the range of 120-150°, the inclination of the left bottom plate 1 and the right bottom plate 2 is not obvious, and the iron filings and engine oil slide down slowly during collection, and the collection efficiency is low; when it is lower than the range of 120-150°, the generated iron filings and Engine oil is easy to be scattered directly on the ground, which is not conducive to collection.

[0029]The cleaning mechanism 8 includes a cleaning rod and bristles arranged on the cleaning rod, and the length of the cleaning rod is equal to the width of the left bottom plate 1 and the right bottom plate 2 . The cleaning rod is slidably arranged on the slideway A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com