Clamping fixture

A clamping and clamping technology, which is applied in the direction of clamping devices, clamps, clamps, etc., can solve problems such as hindering the precise positioning of the workpiece pallet and hindering the correct operation of the clamping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

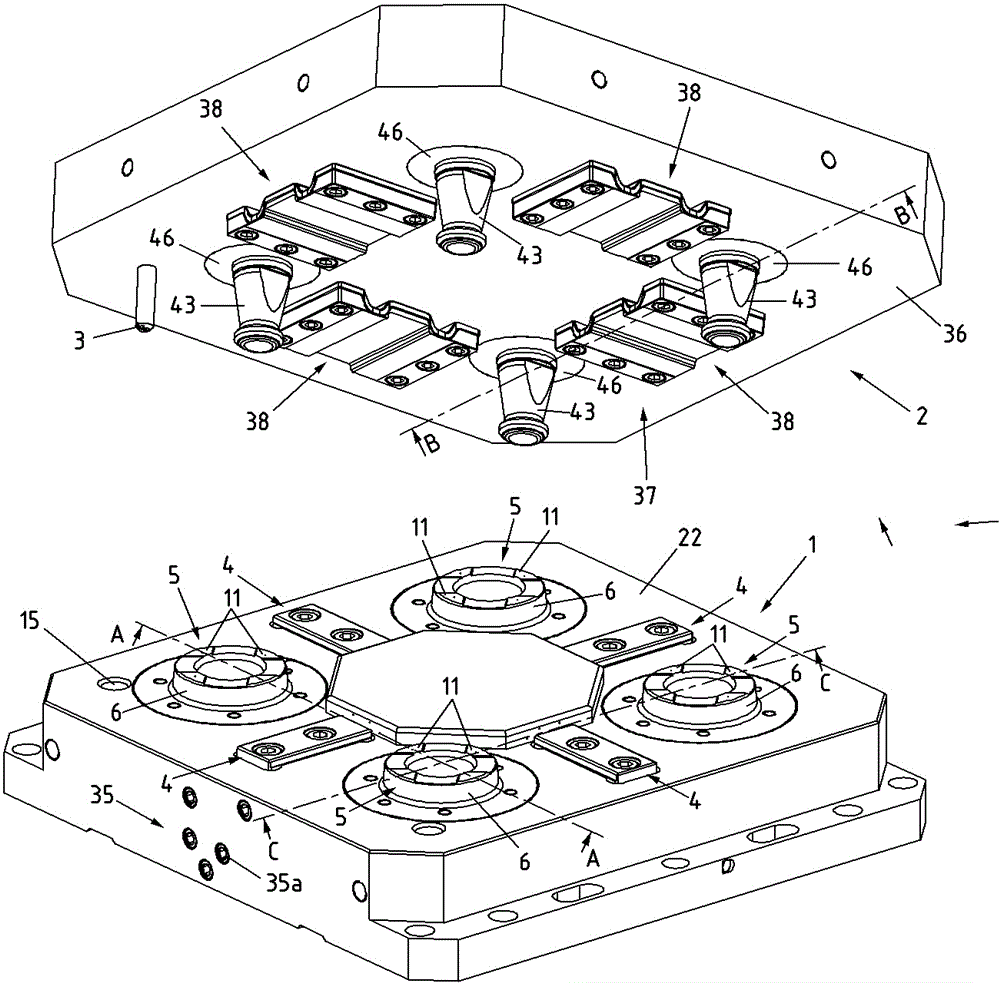

[0019] Reference now figure 1 , the main components of the clamping fixture are illustrated in a perspective view. The clamping fixture comprises a clamping base member 1 and a workpiece pallet 2 fixed in position in the area of the machine tool. As shown, the clamping fixture is used in particular to clamp large and / or heavy workpieces fixedly in place in the work area of a machine tool (eg, a milling machine, a grinding machine or an EDM machine or a lathe). In this context, large and heavy is understood as a workpiece as large as about 500x500x500 mm and weighing several hundred kilograms.

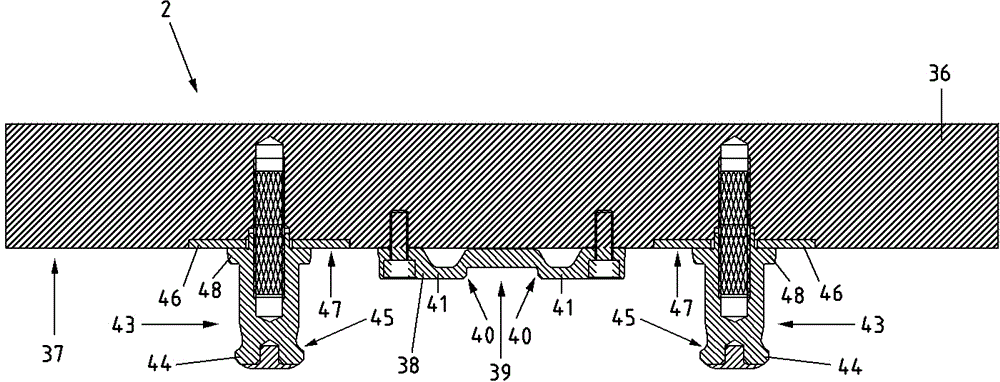

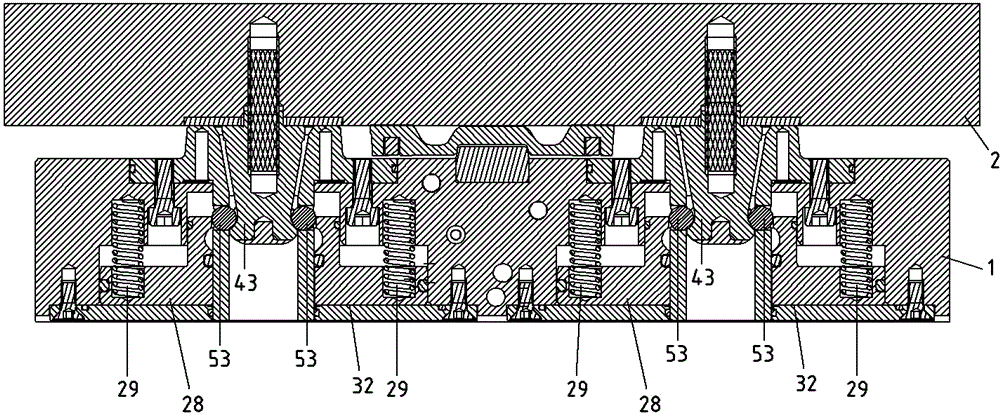

[0020] The clamping base member 1 features a basic element 22 fitted with four clamping devices 5, while the workpiece pallet 2 comprises a main element 36 adapted to four clamping pins 43, which clamp The latch 43 is arranged corresponding to the clamping device and can be fixedly clamped in place in the clamping device 5 . In order to achieve precise positioning of the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com